Special polypropylene filament needle-punched drainage geotechnical cloth for tunnels, preparation method and preparation system

A polypropylene, soil-draining technology, used in needle punching machines, stretch spinning, non-woven fabrics, etc., can solve the problems of poor mechanical properties, hydraulic properties and chemical resistance of non-woven fabrics, loss of protective geomembrane It is difficult to achieve problems such as water permeability and drainage, and achieve good hydraulic performance, good drainage capacity and water permeability, and the effect of reducing monofilament breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

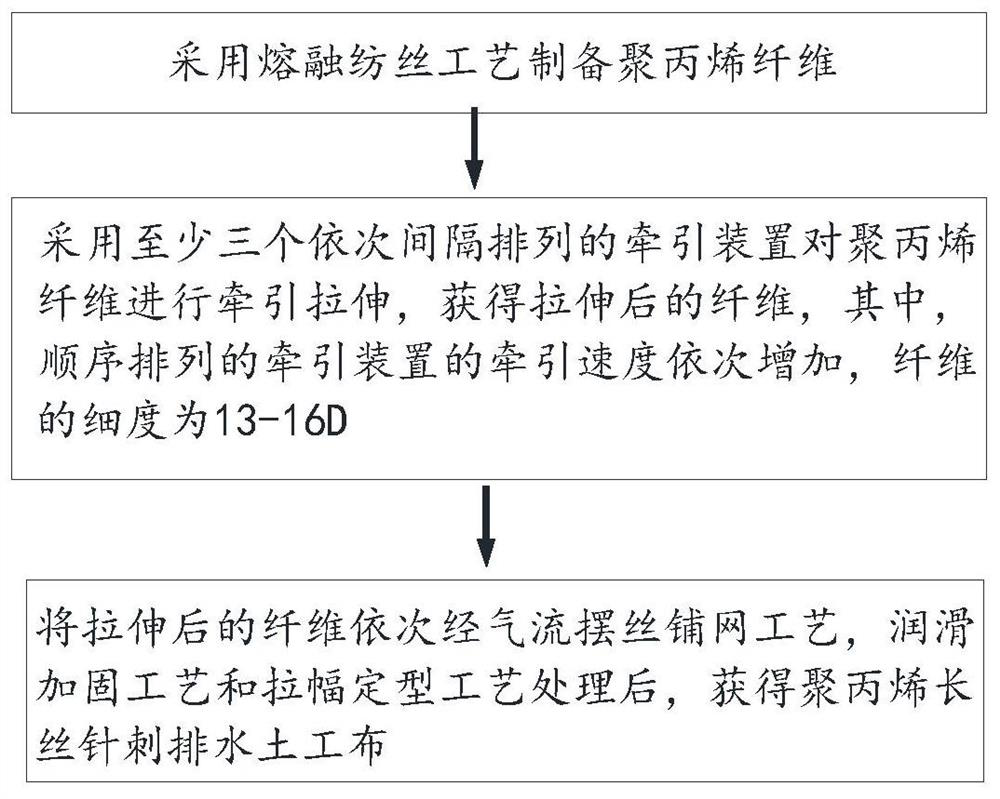

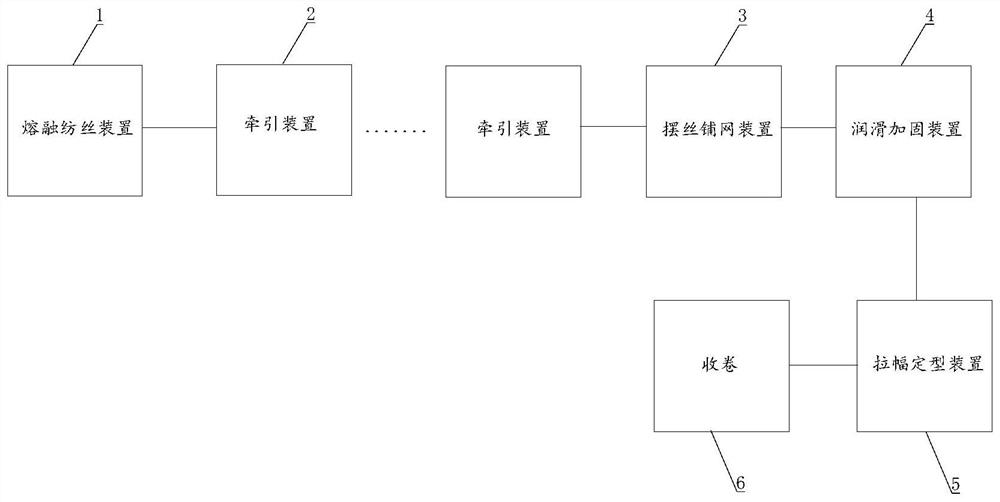

[0033] Such as figure 1 As shown, this embodiment provides a method for preparing a polypropylene filament needle-punched drainage geotextile for tunnels, including the following steps:

[0034] S1) preparing polypropylene fibers by melt spinning process;

[0035] S2) Pulling and stretching the polypropylene fiber by using at least three traction devices arranged in sequence at intervals to obtain stretched fibers, wherein the traction speeds of the sequentially arranged traction devices increase sequentially, and the fineness of the fibers is 13-16 dtex;

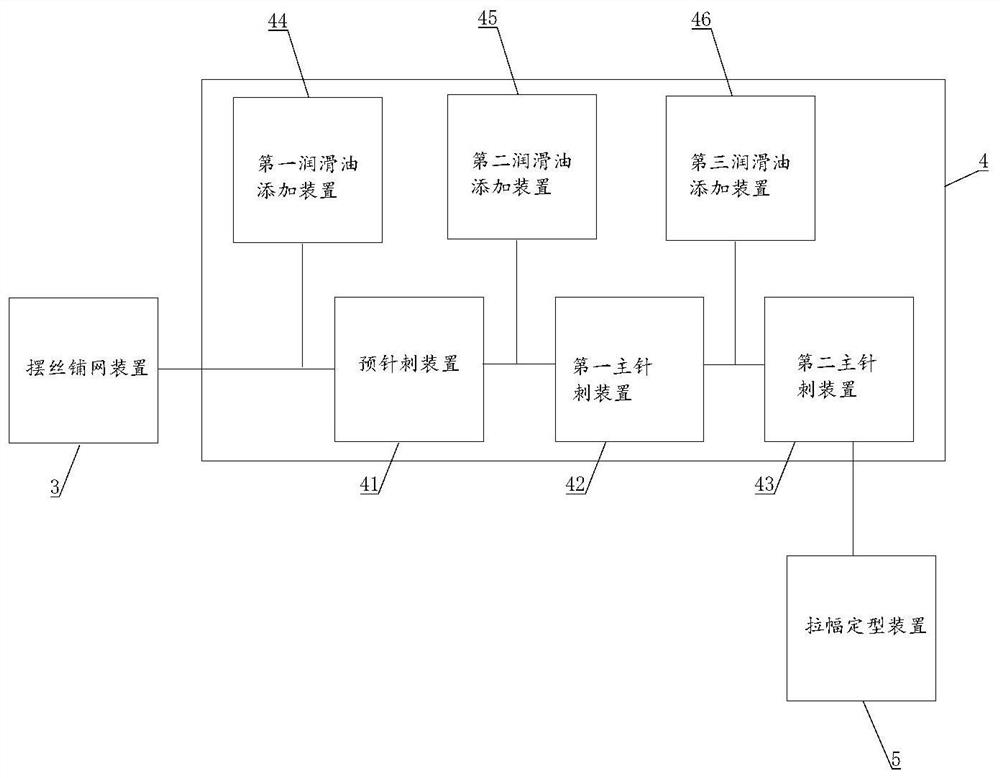

[0036] S3) After the stretched fibers are sequentially processed by an air-flow swing wire laying process, a lubrication reinforcement process and a tentering shaping process, a polypropylene filament needle-punched drainage geotextile is obtained.

[0037] Specifically, the pulling speed of the pulling device is 100-2000m / min.

[0038] Specifically, it includes arranging seven traction devices in sequence; the increasing...

Embodiment 1

[0056] Sample 1 preparation process is as follows: comprise the following steps:

[0057] 101) preparing polypropylene fibers by melt spinning process;

[0058] 102) Pulling and stretching polypropylene fibers by using seven sequentially arranged traction devices at intervals to obtain stretched fibers, wherein the increasing multiples of the traction speeds of the sequentially arranged traction devices decrease successively, and the fineness of the stretched fibers The degree is 15dtex;

[0059] Among them, seven traction devices are arranged in sequence, the traction speed of the first traction device, the second traction device, the third traction device, the fourth traction device, the fifth traction device, the sixth traction device and the seventh traction device is 100m / min, 400m / min, 800m / min, 1200m / min, 1600m / min, 2000m / min and 1950m / min; the temperature of the drafting rollers of the seven drawing devices is 120°C, 120°C, 120°C, 130°C, 130°C ℃, 130℃, 80℃;

[0060...

Embodiment 2

[0074] Sample 4, sample 5 and sample 6 described in the present invention are improvements on the basis of Example 1. The technical content disclosed in Example 1 will not be described repeatedly, and the content disclosed in Example 1 also belongs to the content disclosed in this Example.

[0075] Prepare sample 4, sample 4 only changes the concentration of lubricant added, the concentration of lubricant is 0g / L, the performance of the obtained geotextile is shown in Table 2.

[0076] Prepare sample 5, sample 5 only changes the concentration of lubricant added, the concentration of lubricant is 5g / L, the properties of the obtained geotextile are shown in Table 2.

[0077] Prepare sample 6, sample 6 only changes the concentration of lubricant added, the concentration of lubricant is 15g / L, the properties of the obtained geotextile are shown in Table 2.

[0078] Sample 4, Sample 5 and Sample 6 are based on Example 1, only changing the concentration of the lubricant, and it is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com