Composite microballoon of monodisperse SiO2 and TiO2 and its prepn process

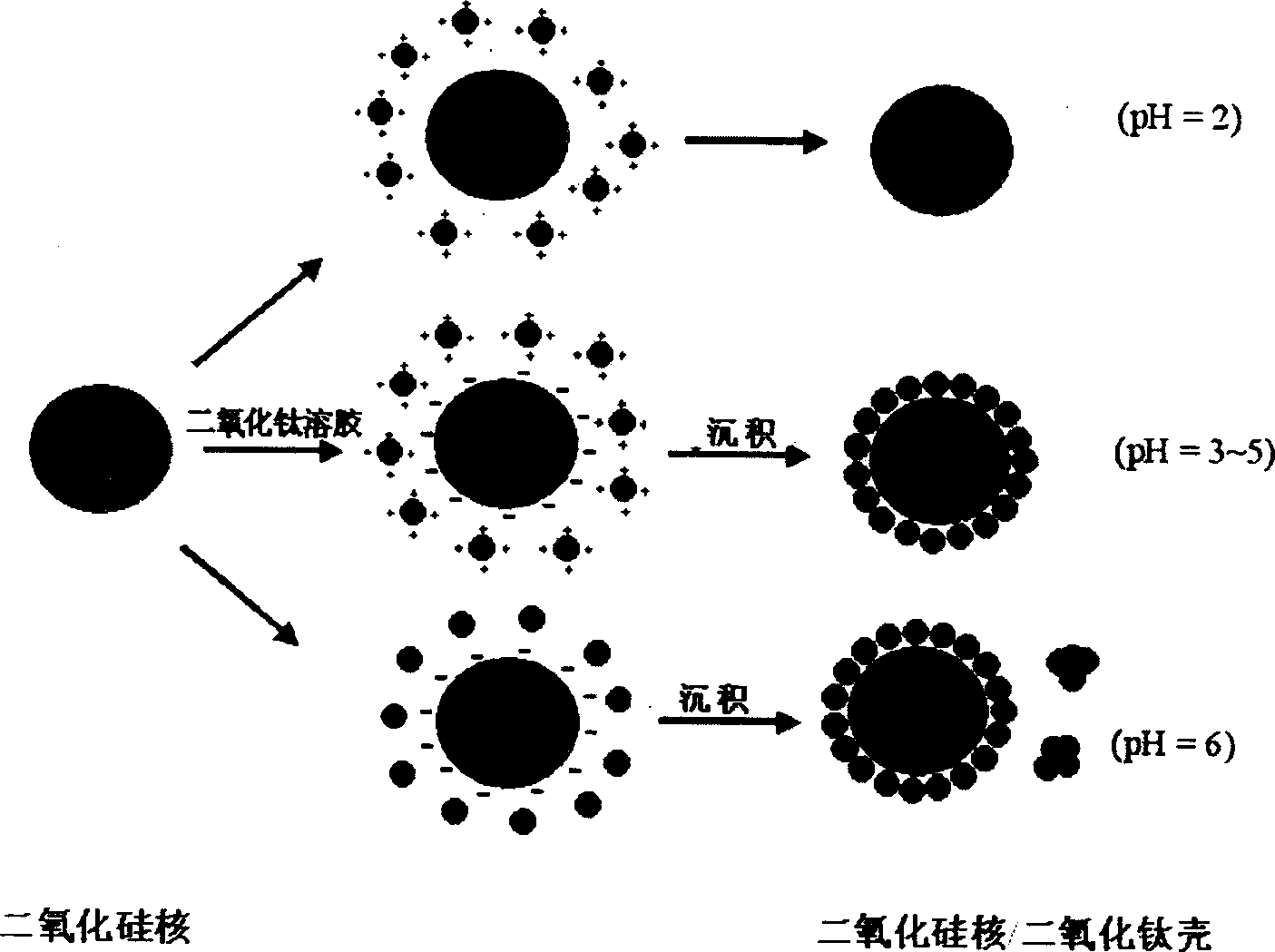

A titanium dioxide and silicon dioxide technology, applied in the field of monodisperse silicon dioxide and titanium dioxide composite microspheres and their preparation, can solve the problems of easy bonding, poor photocatalytic activity and adsorption capacity, and difficulty in obtaining pure titanium dioxide microsphere particles. , to achieve the effect of high specific surface area and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

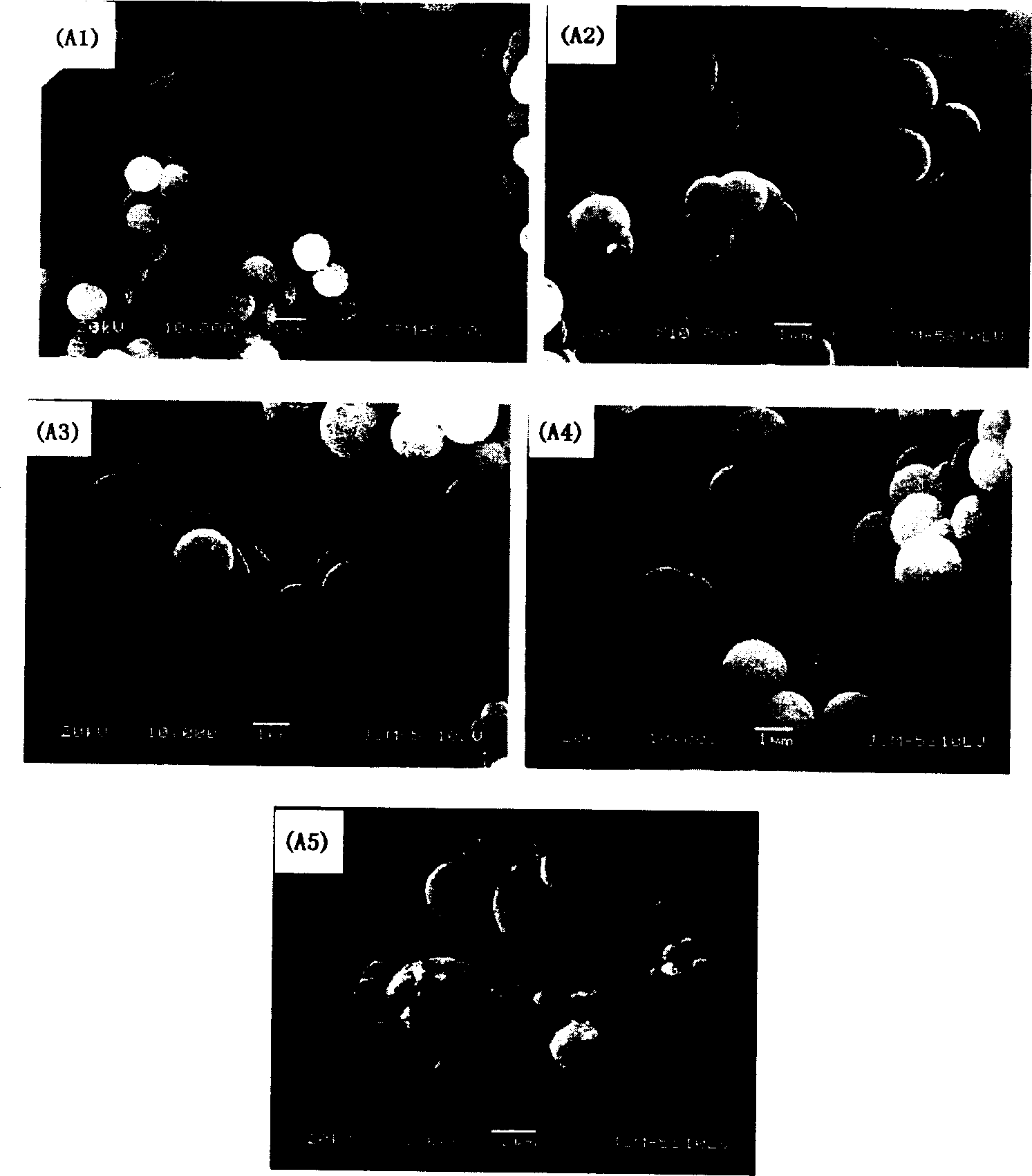

[0035] Dissolve dodecylamine in a mixed solution composed of 160 milliliters of ethanol and 100 milliliters of distilled water under the action of magnetic stirring. After the dodecylamine is completely dissolved, add tetraethyl orthosilicate dropwise to the above mixed solution. The molar concentrations of dodecylamine and ethyl tetrasilicate are respectively 0.024 and 0.18 mol / liter; after reacting for 4 hours, a white precipitate is obtained; the white precipitate obtained is filtered, then dried in a vacuum oven at 80°C for 6 hours, Finally, it is calcined at 600° C. for 6 hours in a muffler furnace to obtain monodisperse silica microsphere raw material with high specific surface area. figure 2 It shows the SEM photo of the prepared silica microspheres. It can be seen from the figure that the particles of the silica microspheres are about 600nm, and the particle distribution is uniform and monodisperse. Table 1 shows the prepared SiO 2 The specific surface area and pore ...

Embodiment 2

[0037] Dissolve 11 ml of butyl titanate in 100 ml of distilled water to generate a white precipitate of titanium hydroxide, then filter, redisperse the resulting white precipitate in 100 ml of distilled water under magnetic stirring, and adjust the pH of the suspension with concentrated nitric acid value to 0.7, and finally the mixed solution was kept at 60°C. After 4 hours of degumming, the titanium hydroxide precipitate was completely dissolved to form a light blue transparent titanium dioxide sol, and the molar concentration of titanium dioxide was 0.3 mol / liter.

Embodiment 3

[0039] Weigh 2 grams of the silica microsphere powder obtained in Example 1, ultrasonically disperse it in 80 ml of distilled water, adjust the pH value of the silica suspension to 0.7 with concentrated nitric acid, and then mix 2 ml of the silica microsphere powder in Example 1 with magnetic stirring. 2 Add the obtained titanium dioxide sol to the silica suspension, then adjust the pH value of the mixture to 4 with 0.5 mol / L sodium hydroxide solution, and stir and react at room temperature 25°C for 3 hours to obtain a white turbid suspension solution , filtered, and then washed with absolute ethanol to obtain a white precipitate 4 times. Finally, the obtained white precipitate was dried in a vacuum drying oven at 80°C for 6 hours, and heat-treated at a high temperature of 600°C for 4 hours to obtain SiO containing anatase phase. 2 with TiO 2 Composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com