Steeping and rubbing type washing machine

A washing machine and clothing technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of insufficient performance such as washing action reliability, water saving, etc., and achieve easy promotion, high washing quietness, and no wear and tear The effect of clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

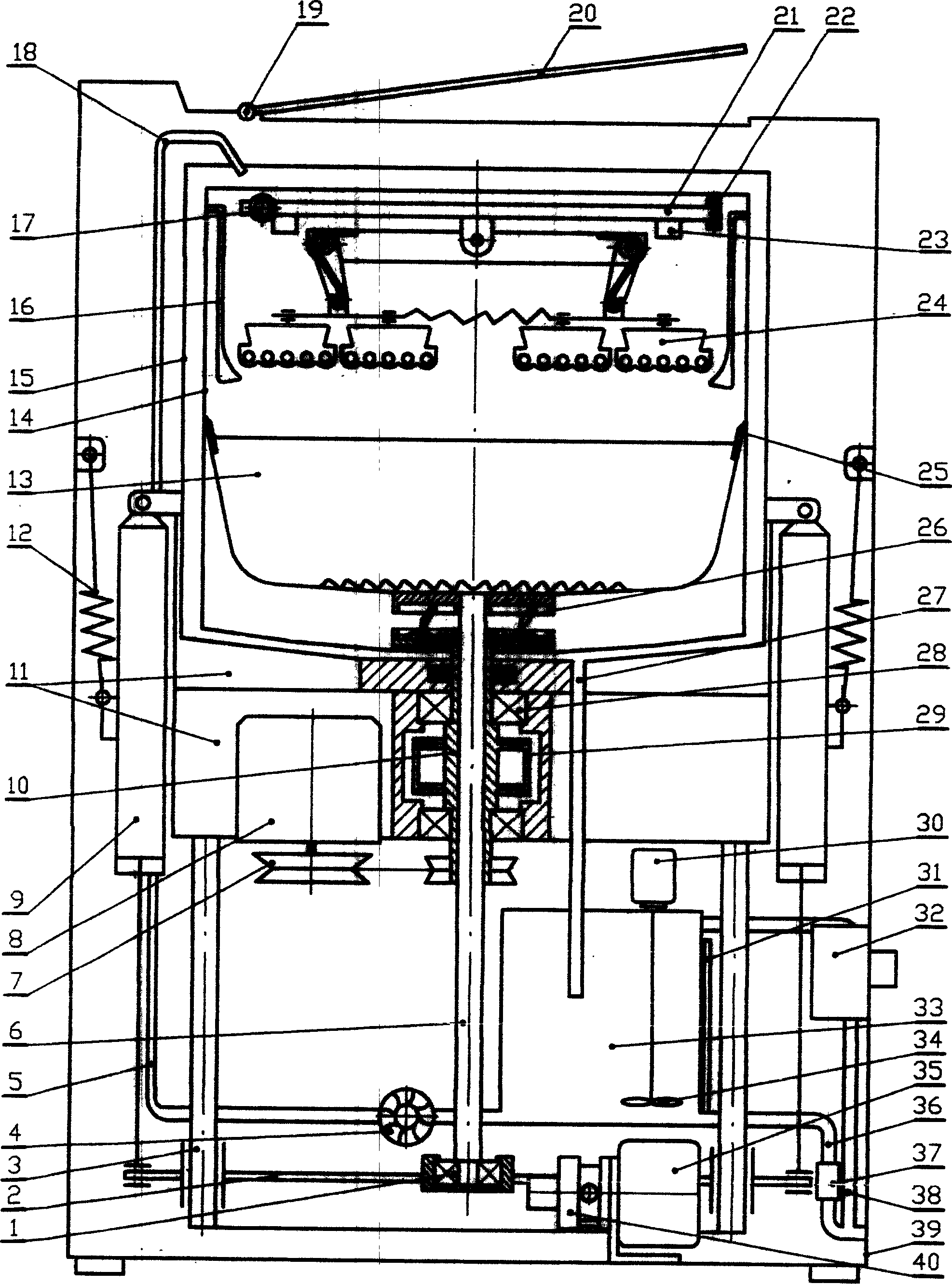

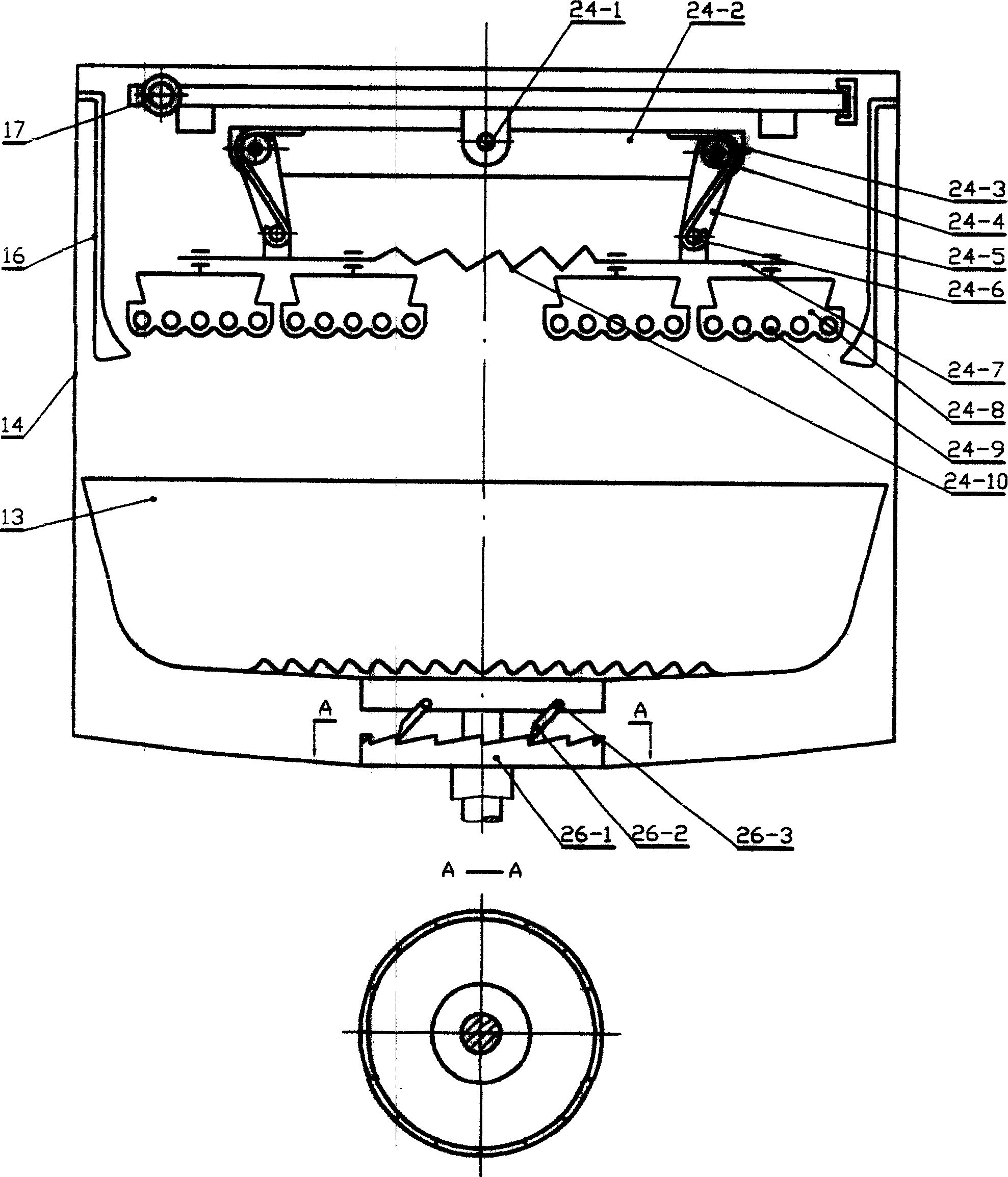

[0019] Such as Figure 1 As shown, the mechanical structure of the present invention is composed of an isolation bearing 1, a crossbeam 2, a guide rod 3, a water guide pipe 5 under a circulating water pump 4k, a lifting mandrel 6, a belt transmission pair 7, a dehydration motor 8, a hydraulic cylinder 9, and a washing inner cylinder Shaft assembly 10, washing outer cylinder frame assembly 11, elastic support 12, washing basin 13, washing inner cylinder 14, washing outer cylinder 15, flexible lever 16, upper gland hinge 17, upper water guide pipe 18, machine cover shaft 19, Machine cover 20, upper gland 21, upper gland lock 22, balance ring 23, floating washing head 24, circlip 25, axial ratchet mechanism 26, lower return pipe 27, support bearing 28, brake disc 29, Stirring motor 30, water level controller 31, pressure control valve 32, water storage tank 33, water stirrer 34, hydraulic motor 35, drain pipe 36, drain valve 37, overflow pipe 38, casing 39, hydraulic pump 40 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com