Antibacterial austenitic stainless steel

An antibacterial stainless steel and austenite technology, which is applied in the field of austenitic antibacterial stainless steel and nickel and chromium antibacterial stainless steel, can solve the problems of decreased corrosion resistance of materials, difficulty in controlling the amount of addition and particle size, and no environmental protection sterilization effect. To achieve the effect of improving antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

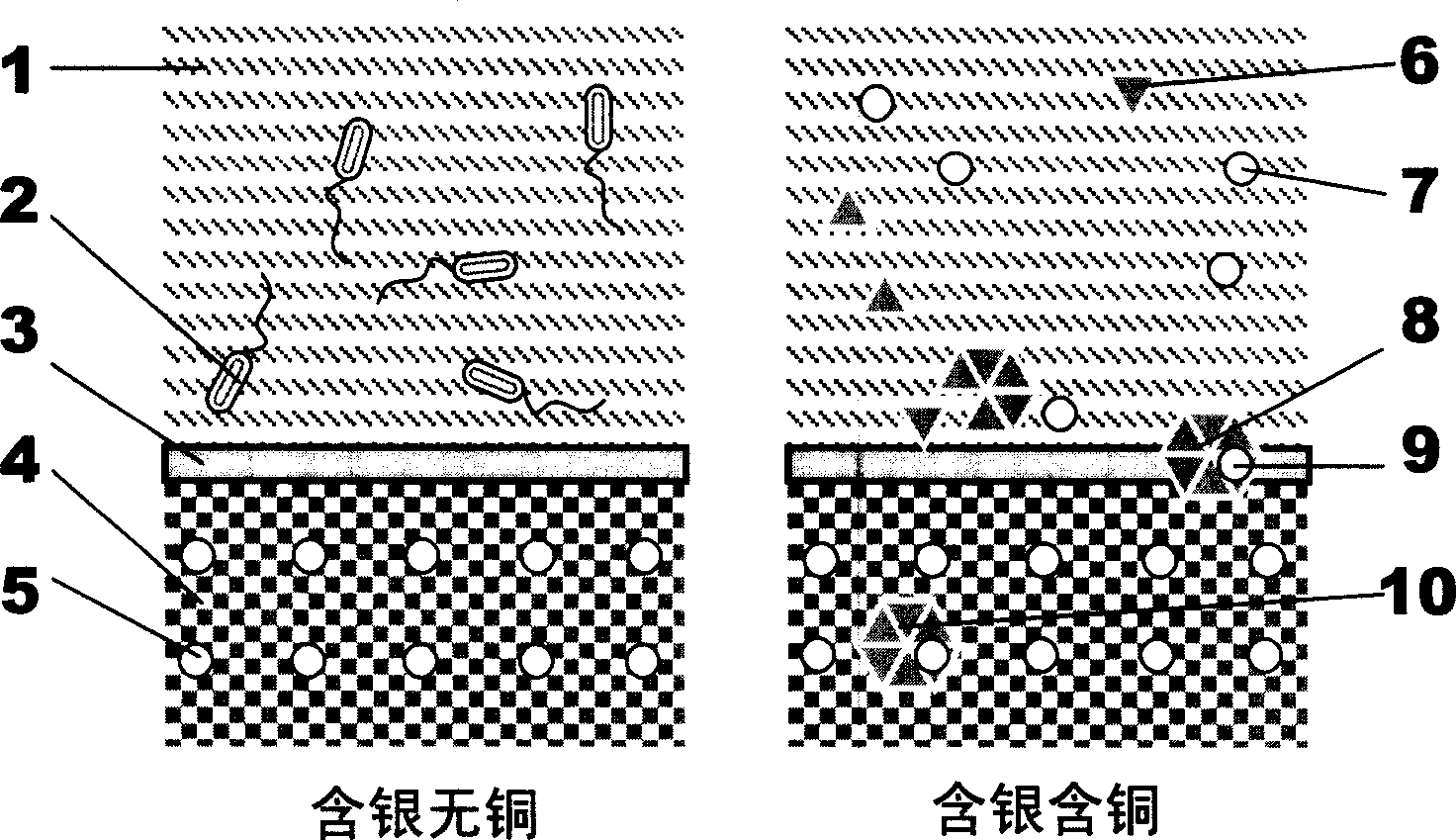

[0013] figure 1 .Comparison of silver with copper and silver without copper in the alloy. 1. Transport liquid, 2. Bacteria, 3. Passive film, 4. Stainless steel, 5. Silver atom, 6. Copper ion, 7. Silver ion, 8. Surface ε-Cu, 9. Dissolved into silver, 10. Internal ε-Cu.

[0014] Use vacuum induction furnace or electric furnace-AOD duplex to smelt stainless steel, cast billets, quench in solution water at 1150°C after forging, aging treatment at 400-700°C, pickling and rust removal, cold rolling to 1mm, annealing, pickling, polishing surface.

[0015] Evaluate the corrosion resistance of stainless steel through the cycle of the following three steps: (1) Spray 5% NaCl aqueous solution at 35°C for 0.5 hours; (2) Store at 60°C and 40% humidity for 1 hour; (3) Store at 40°C and 95% humidity for 1 hour. The three stages are one cycle, and after 30 cycles, the area ratio of the corrosion of the test piece is measured.

[0016] Assess the antibacterial test, according to the Pharm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com