Manufacturing method of diamond wire drawing mould

A wire drawing die and manufacturing method technology, which are applied in the directions of wire drawing die, metal wire drawing, metal drawing forming tools, etc., can solve the problems of increasing the manufacturing cost of a single die, increasing the occupation time of a machine tool, increasing the processing and manufacturing time of a single die, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

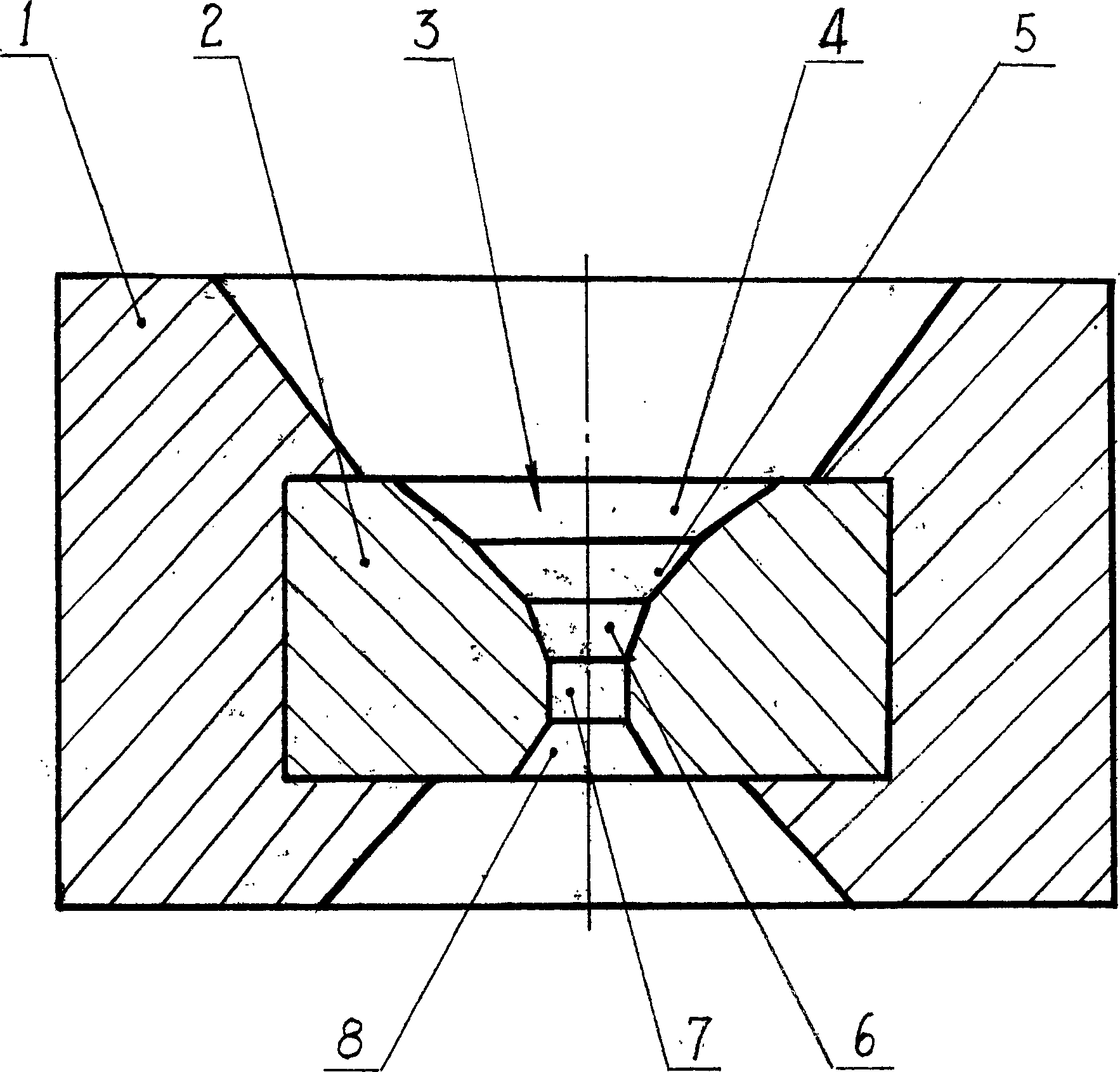

[0021] exist figure 1 , a diamond wire drawing die is shown in longitudinal section. The wire drawing die jacket 1 and the wire drawing die 2 are assembled together by cold pressing or hot pressing, and the wire drawing die 2 has a hole 3, which is composed of the entrance area 4, the lubrication area 5, the working area 6, The sizing area 7 and the outlet area 8 are composed.

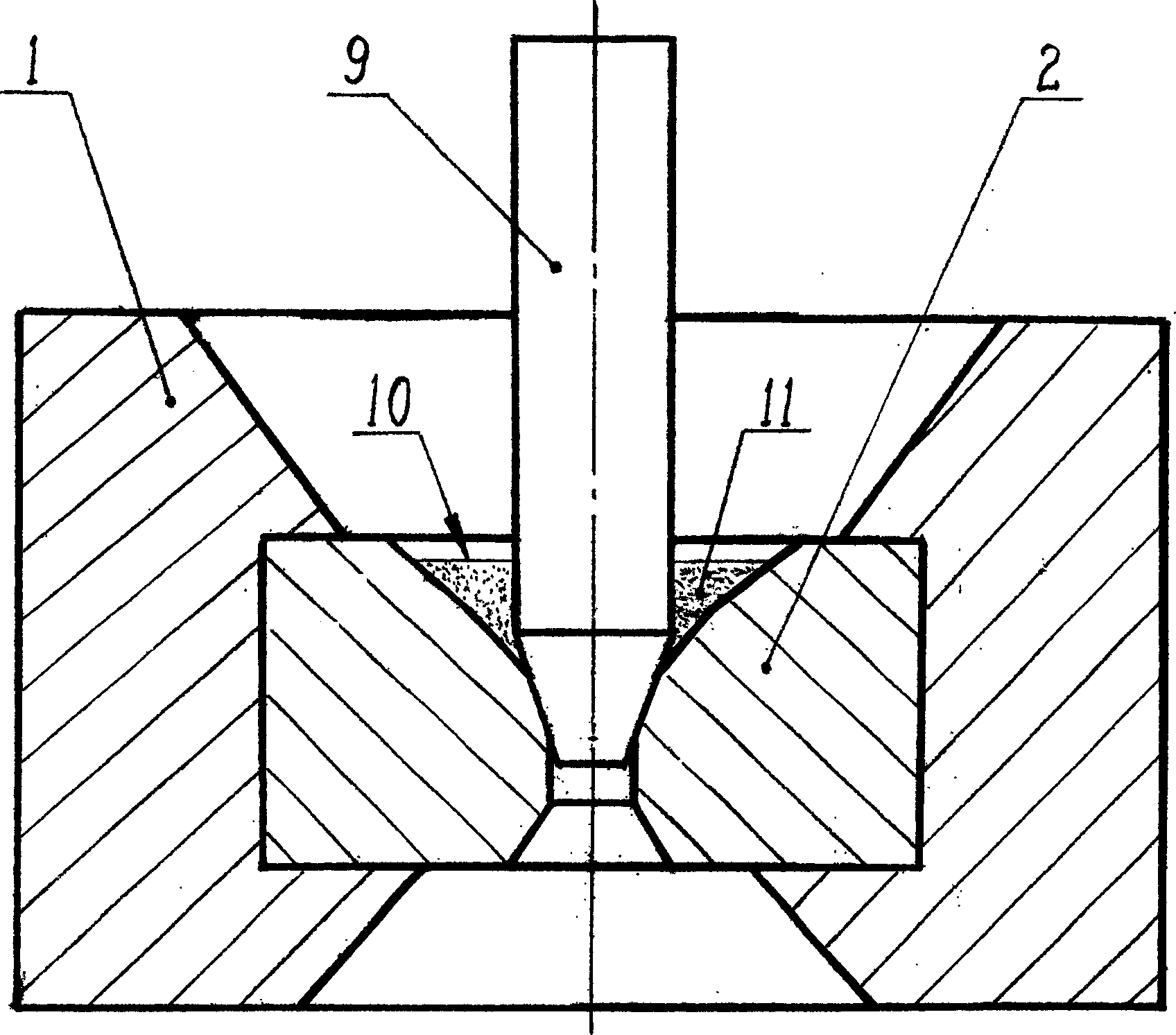

[0022] exist figure 2 In, the method of mechanical grinding of diamond wire drawing die is shown in the form of longitudinal sectional view. Wherein the number 9 is a grinding needle, the number 10 is a grinding powder, and the number 11 is a grinding additive. During the grinding process, grinding needles 9 of different specifications should be selected according to the different shapes and sizes of the processing areas. The selection of grinding powder and grinding additives should be selected according to different mechanical grinding. When coarsely grinding, grinding powder 10 can select No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com