Observing method of metallographic structure of equiatomic platinum-cobalt alloy

A technology of equal atomic ratio and metallographic structure, which is applied in the direction of measuring devices, preparation of test samples, material analysis through optical means, etc. Uniform and easy to control, optimize the effect of processing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

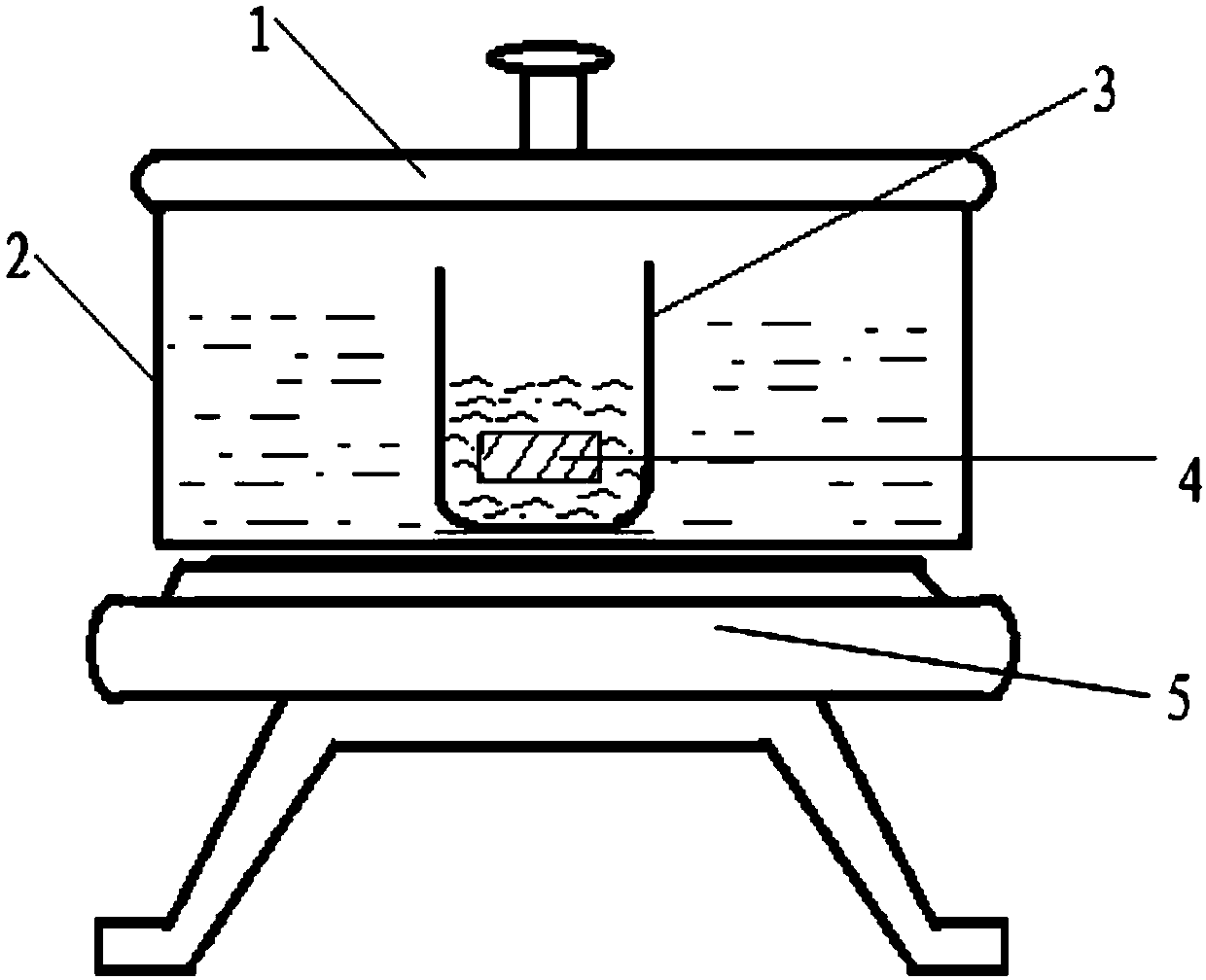

[0032] The observation method of the PtCo alloy metallographic structure of the present embodiment equiatomic ratio comprises the following steps:

[0033] Step 1. Cutting and inlaying of the PtCo alloy sample 4 of equal atomic ratio: Cut the PtCo alloy sample 4 of equal atomic ratio on the PtCo alloy plate of equal atomic ratio. Since the material is hard and brittle and the specification is a square bar, electric The wire spark cutting method is used to cut the sample. The molybdenum wire ≤φ0.12 is used for cutting. The cutting voltage is 70V, the current is 0.4A, and the pulse width is 0. The size of the sample taken is: length×width×height=9mm×8mm× 6mm, the weight of the PtCo alloy sample 4 of the equiatomic ratio taken by weighing is 5.76g, then the PtCo alloy sample 4 of the equiatomic ratio is placed in the mold, and the PtCo alloy sample of the equiatomic ratio is added to the PtCo alloy sample of the equiatomic ratio. Sample 4 is completely covered, and the thickness ...

Embodiment 2

[0040] The observation method of the PtCo alloy metallographic structure of the present embodiment equiatomic ratio comprises the following steps:

[0041] Step 1. Cutting and inlaying of the PtCo alloy sample 4 of equal atomic ratio: Cut the PtCo alloy sample 4 of equal atomic ratio on the PtCo alloy plate of equal atomic ratio. Since the material is hard and brittle and the specification is a square bar, electric The wire spark cutting method is used to cut the sample. The molybdenum wire ≤φ0.12 is used for cutting. The cutting voltage is 70V, the current is 0.4A, and the pulse width is 0. The size of the sample taken is: length×width×height=9.2mm×8.6 mm × 5.3mm, the weight of the PtCo alloy sample 4 of equiatomic ratio taken by weighing is 6.23g, then the PtCo alloy sample 4 of equiatomic ratio is placed in the mould, and toothbrush powder is added to make the equiatomic ratio The PtCo alloy sample 4 is completely covered, and the thickness of the covered denture base powde...

Embodiment 3

[0048] The observation method of the PtCo alloy metallographic structure of the present embodiment equiatomic ratio comprises the following steps:

[0049] Step 1. Cutting and inlaying of the PtCo alloy sample 4 of equal atomic ratio: Cut the PtCo alloy sample 4 of equal atomic ratio on the PtCo alloy plate of equal atomic ratio. Since the material is hard and brittle and the specification is a square bar, electric The wire spark cutting method is used to cut the sample. The molybdenum wire ≤φ0.12 is used for cutting. The cutting voltage is 70V, the current is 0.4A, and the pulse width is 0. The size of the sample taken is: length×width×height=8.9mm×7.8 mm × 6.2mm, the weight of the PtCo alloy sample 4 of equiatomic ratio taken by weighing is 5.49g, then the PtCo alloy sample 4 of equiatomic ratio is placed in the mould, and toothbrush powder is added to make the equiatomic ratio The PtCo alloy sample 4 is completely covered, and the thickness of the covered denture powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com