Low-temperature region sewage treatment equipment and method

A technology of sewage treatment equipment and sewage treatment methods, which is applied in the fields of water/sewage multi-stage treatment, biological water/sewage treatment, heating water/sewage treatment, etc., which can solve the problems of poor sewage treatment effect, unsatisfactory discharge, and high operating costs. , to achieve good thermal insulation effect, improve utilization rate, and good purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

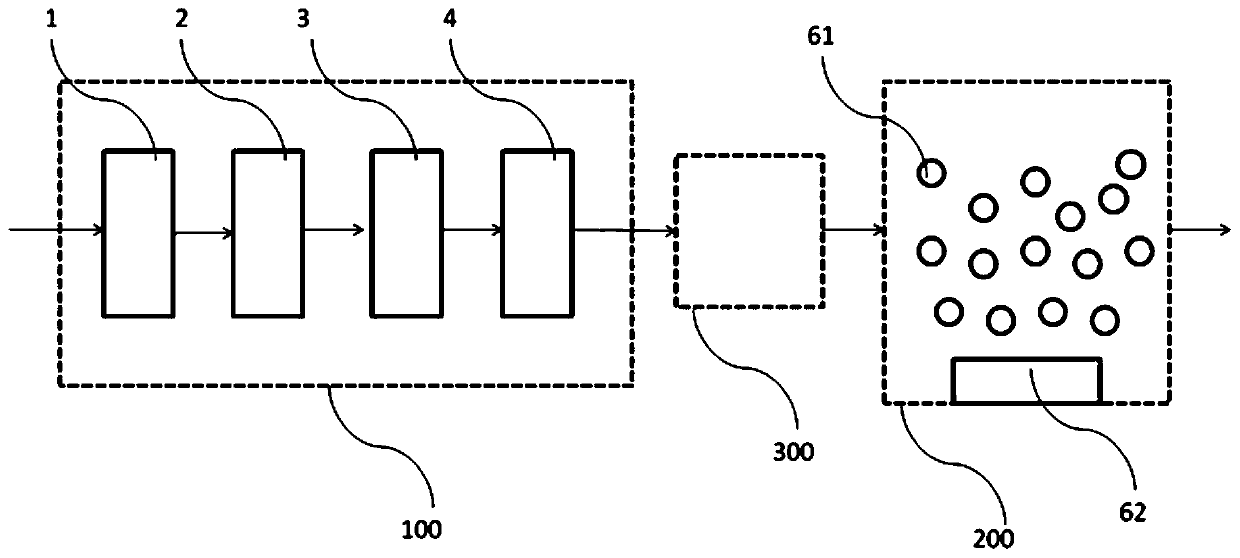

[0039] According to a preferred embodiment of the present invention, the primary treatment unit includes a water distribution well 1 , a fine grid 2 and a regulating tank 3 arranged in sequence.

[0040] In the present invention, after the sewage is treated in the grit chamber, it enters the water distribution well, so as to reduce the impact of flow changes on the subsequent treatment system.

[0041] Further, a water pump is provided between the distribution well 1 and the fine grid, and between the fine grid and the regulating tank.

[0042] Furthermore, the gap between the bars of the fine grid 2 is 4-8mm, so as to intercept suspended matter and floating matter.

[0043] Among them, the sewage removes larger floating and suspended solids in the fine grid, and then enters the regulating tank to uniform the water quality and water quantity.

[0044] According to a preferred embodiment of the present invention, the primary treatment unit further includes an air flotation dev...

Embodiment 1

[0219] The sewage treatment equipment in the low temperature area described in this embodiment is specifically as follows:

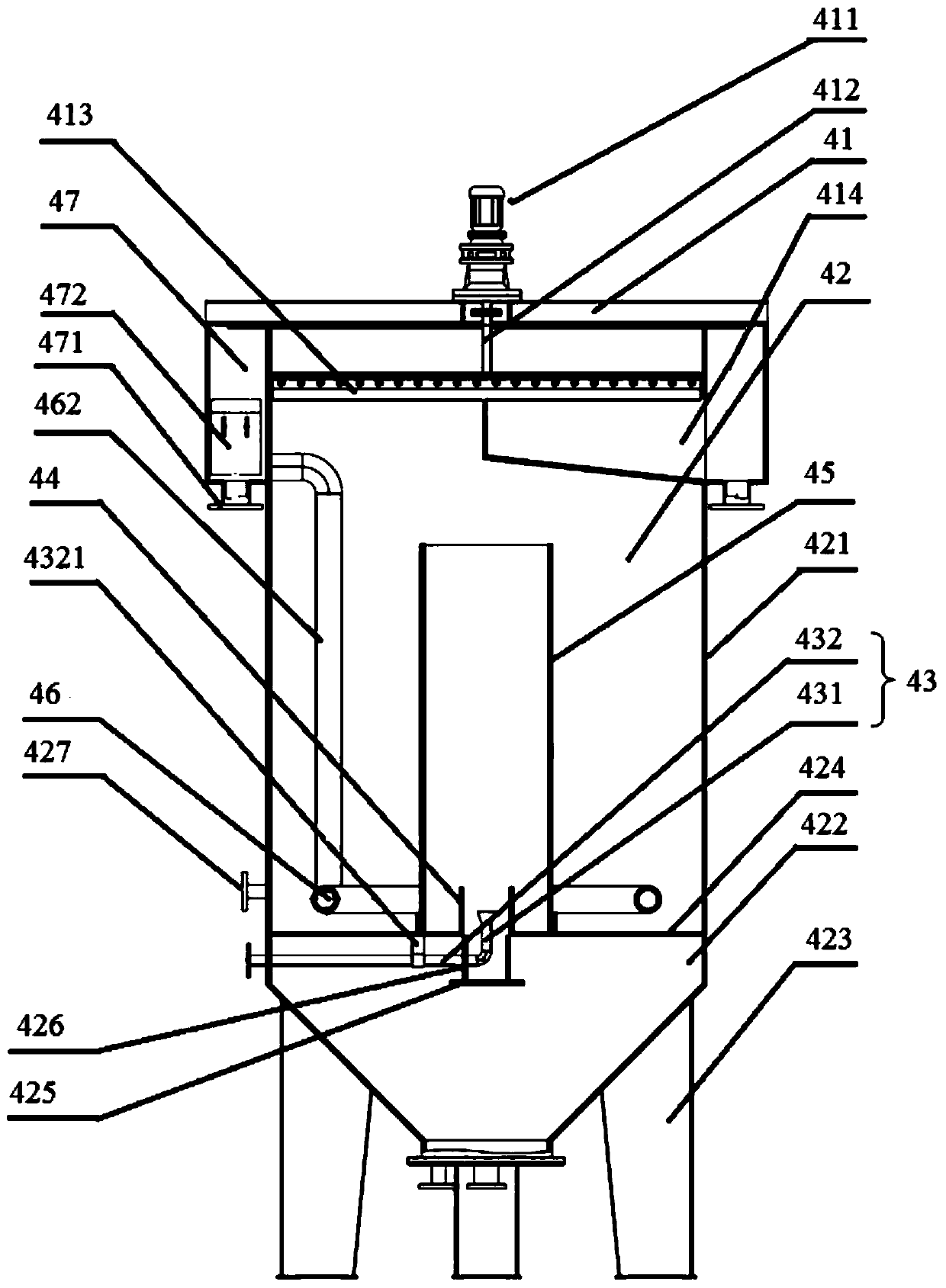

[0220] In the primary treatment unit, the water distribution well, the fine grid, the adjustment tank and the air flotation device are connected in sequence, and the gap between the grids of the fine grid is 6mm.

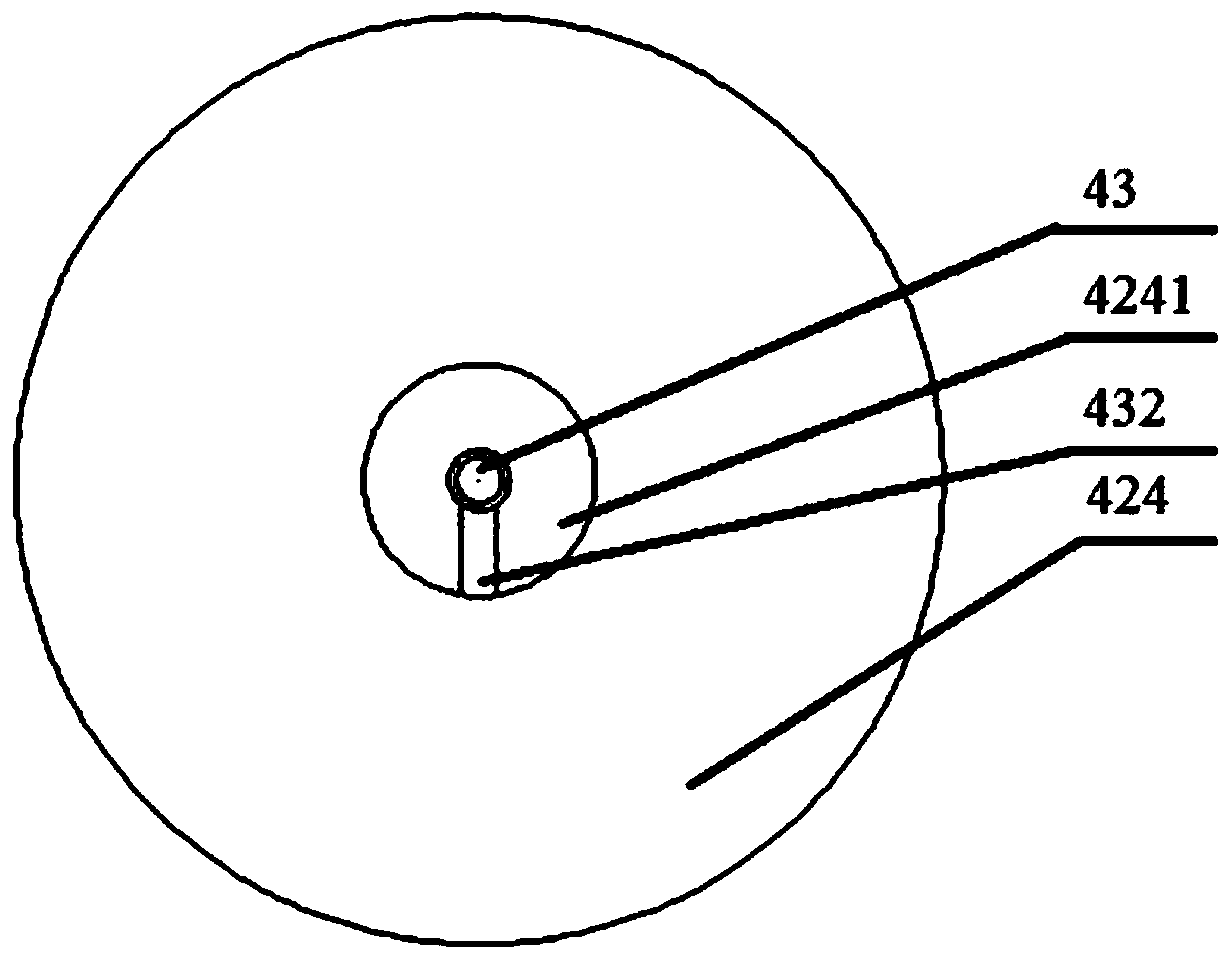

[0221]In the air flotation device: the ratio of the vertical height of the water baffle to the top of the tank and the vertical height of the water baffle to the bottom of the tank is 13:1; the diameter of the water passing hole and the diameter of the water baffle The ratio is 1:9; the diameter ratio of the circular deflector to the water baffle is 1:6; the vertical height of the fixed bracket is 1 / 4 of the vertical height from the water baffle to the bottom of the tank; the vertical pipe The vertical height from the top to the water barrier is 100mm; the ratio of the vertical height of the steady flow release part to the vertical height of t...

Embodiment 2

[0233] This embodiment is similar to Embodiment 1, the difference is that in the air flotation device: the ratio of the vertical height of the water-repelling baffle from the top of the tank to the vertical height of the water-repelling baffle from the bottom of the tank is 6:1; The diameter ratio of the diameter of the round water hole to the water baffle is 1:6; the diameter ratio of the circular deflector to the water baffle is 1:4; the vertical height of the fixing bracket is the distance from the water baffle to the bottom of the tank 1 / 3 of the vertical height of the vertical pipe; the vertical height of the top of the vertical pipe from the water barrier is 80mm; the ratio of the vertical height of the steady flow release part to the vertical height of the tank is 3:40; The cross-sectional diameter is 1 / 4 of the cross-sectional diameter of the columnar tank; the vertical height of the guide cylinder is 3 / 5 of the vertical height of the columnar tank; there are two rows o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com