Thermal interface material and its production method

A technology of thermal interface material and manufacturing method, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high thermal conductivity of thermal interface materials, large thickness of thermal interface materials, and unordered arrangement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

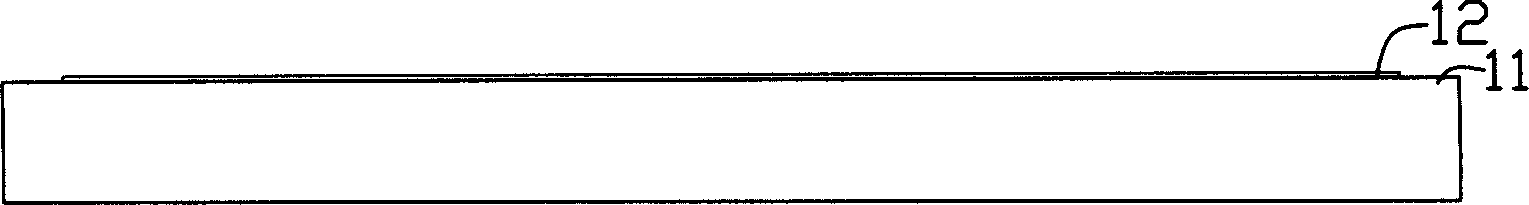

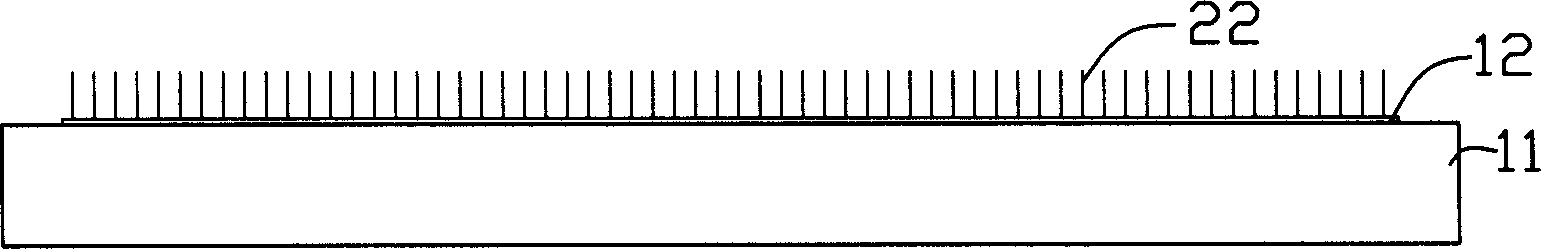

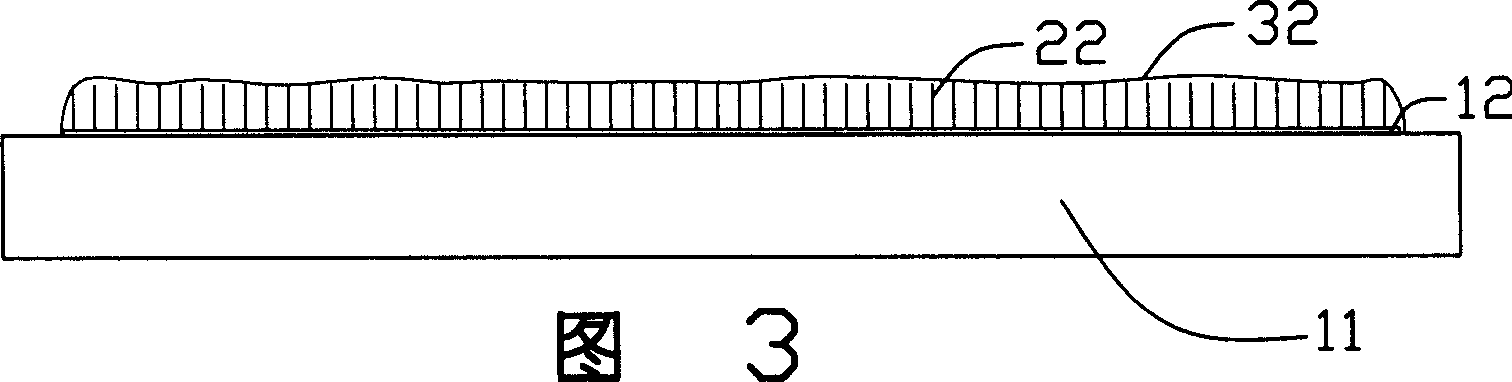

[0024] see figure 1 and figure 2 Firstly, a catalyst layer 12 is uniformly deposited on a substrate 11, and the method can be accomplished by thermal deposition, electron beam deposition or sputtering. The material of the substrate 11 can be glass, quartz, silicon or alumina. In this embodiment, porous silicon is used, the surface of which is a porous layer, and the diameter of the pores is extremely small, generally less than 3 nanometers. The material of the catalyst layer 12 can be iron, cobalt, nickel and alloys thereof, and iron is selected as the catalyst material in this embodiment.

[0025] Oxidize the catalyst layer 12 to form catalyst particles (not shown in the figure), and then place the substrate 11 distributed with the catalyst in a reaction furnace (not shown in the figure), and feed carbon source gas at 700-1000 degrees Ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com