Device and method for producing a molded pulp part and molded pulp part

A technology for molding parts and control devices is applied in the field of devices for manufacturing fiber molding parts to achieve the effect of expanding the filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

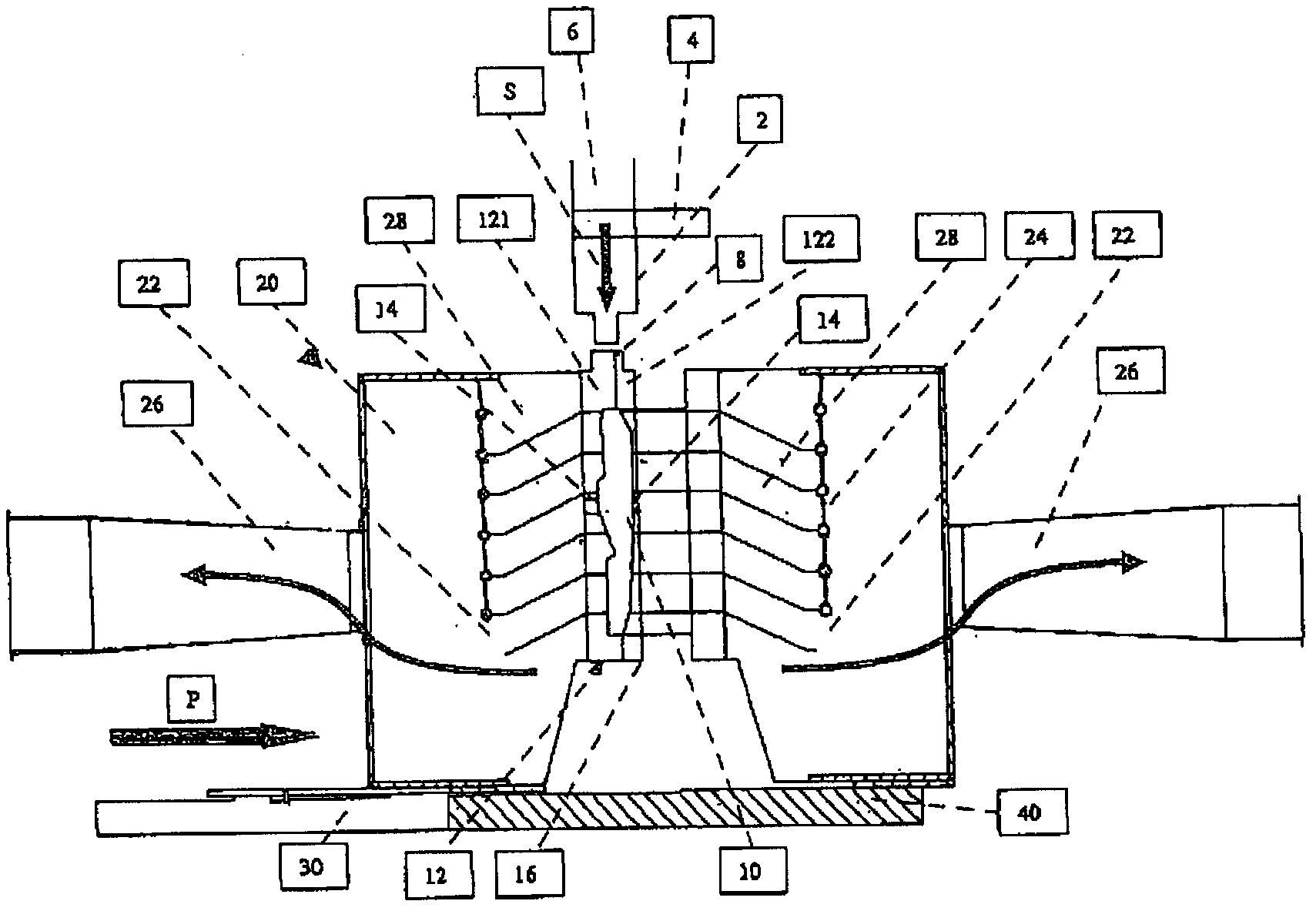

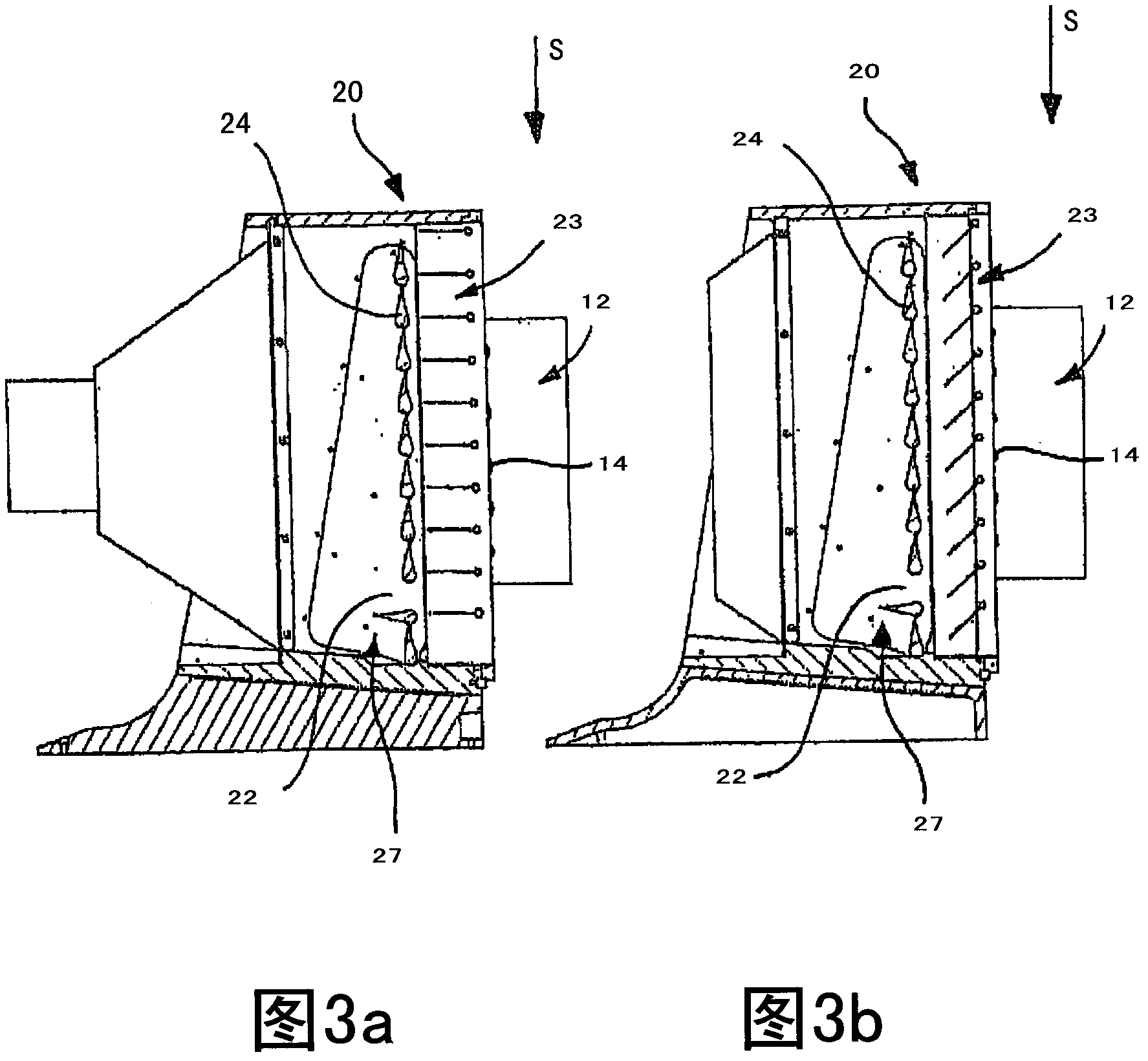

[0042] exist figure 1 A device for producing fiber moldings is shown in schematic cross-section in . The device has a fiber delivery device 2 in the form of a filler neck, which is equipped with a heating device and a heat exchanger 6 . The fibers to be introduced into the mold 12 are provided in the filling nozzle of the fiber feed device 2 and are introduced pneumatically via the introduction opening 8 shown schematically in the region of the parting line of the mold 12 Mold 12. The mold 12 consists of two mold parts 121 , 122 which are arranged on the tool receiver. There may also be more than two mold parts. The left mold part 121 and its associated tool holder are mounted displaceably on the slide 30 on the frame 40 . A pressure P can be applied via the slide 30 in order to displace the left mold part 121 in the direction of the right mold part 122 . It is likewise possible to move the mold parts 121 , 122 away from each other in order to increase the volume of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com