Method for preparing visible-light responsive TiO2-doped high-temperature molten salt

A high-temperature melting and high-temperature molten salt technology, applied in chemical instruments and methods, luminescent materials, hydrogen production, etc., can solve the problems affecting the application performance of nano-photocatalytic materials, easy agglomeration, and instability of nano-photocatalytic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

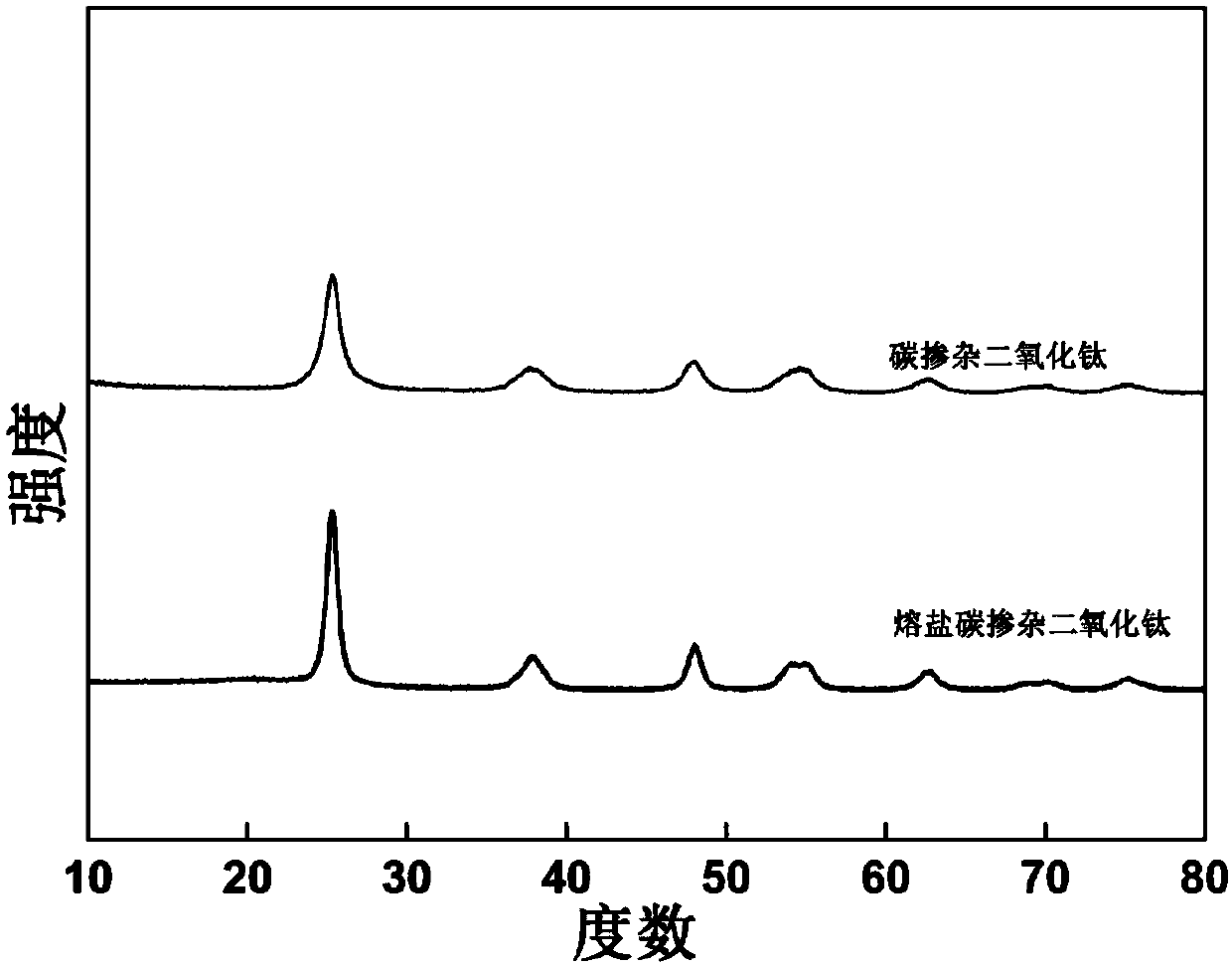

[0031] Weigh 500 g of LiCl, NaCl, and KCl (molar ratio 47.5:15:37.5) and mix them evenly, put them into a quartz crucible, raise the temperature at 5°C / min to 300°C and keep it for 24 hours to remove the moisture in the salt, then raise the temperature at 10°C / min To 520 ℃, keep warm for half an hour to completely melt the salt and form a uniform mixed salt. Weigh 2g of melamine powder, press it into a tablet with a tablet machine, wrap it with nickel foam and tie it to a molybdenum wire, put it in a high-temperature molten salt and react for 60min, and the reaction is carried out under an inert atmosphere of Ar. The nickel foam was taken out and soaked in deionized water for 24 hours, the nickel foam was peeled off, and the product was collected. The obtained product was washed by centrifugation with deionized water and ethanol four times each, at a rotation speed of 5000 r / min, for 3 minutes. Then the product was dried at 80° C. to obtain molten salt carbonized nitrogen nan...

Embodiment 2

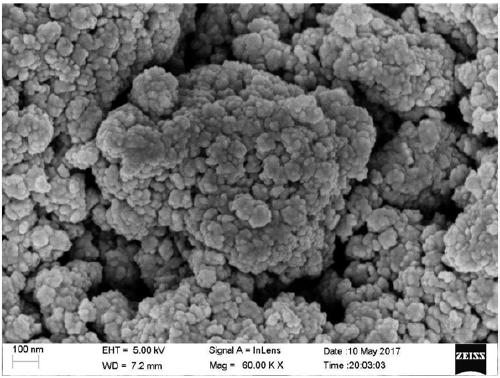

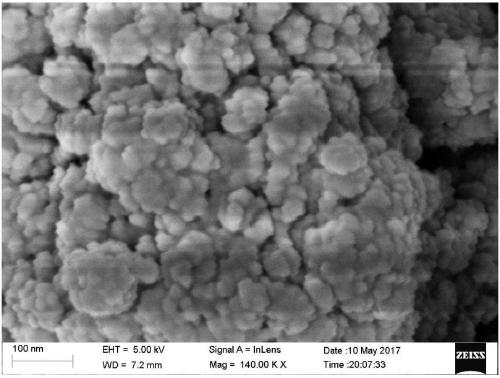

[0033] Weigh 500 g of LiCl, NaCl, and KCl (molar ratio 47.5:15:37.5) and mix them evenly, put them into a quartz crucible, raise the temperature at 5°C / min to 300°C and keep it for 24 hours to remove the moisture in the salt, then raise the temperature at 10°C / min Heat to 520°C, keep warm for half an hour until the salt is completely melted and a uniform mixed salt is formed. Weigh 2g metatitanic acid (TiO(OH) 2) powder, made into tablets with a tablet machine, wrapped with foamed copper and put into high-temperature molten salt to react for 60min, and the reaction was carried out under an inert atmosphere of Ar. The nickel foam was taken out and soaked in deionized water for 24 hours, and the copper foam was peeled off to collect the product. The obtained product was washed by centrifugation with deionized water and ethanol four times each, at a rotation speed of 5000 r / min, for 3 minutes. Then the product was dried at 80° C. to obtain molten salt titanium dioxide nanometer...

Embodiment 3

[0035] Weigh 500g of LiCl, NaCl, and KCl (molar ratio 47.5:15:37.5) and mix them evenly, put them into a quartz crucible, dry at 300°C for 24 hours to remove the moisture in the salt, and then raise the temperature to 520°C at 10°C / min , keep warm until the salt is completely melted. Weigh 2g metatitanic acid (TiO(OH) 2 ) powder and 100mg melamine powder were mixed evenly, pressed into tablets with a tablet machine, wrapped with foamed nickel and put into high-temperature molten salt to react for 60min, and reacted in N 2 in the atmosphere. The nickel foam was taken out and soaked in deionized water for 24 hours, the nickel foam was peeled off, and the product was collected. The obtained product was washed by centrifugation with deionized water and ethanol four times each, at a rotation speed of 5000 r / min, for 3 minutes. Then the product was dried at 80° C. to obtain molten salt titanium dioxide / nitrogen carbide composite nanometer photocatalytic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com