Technological method and device for preparing biaxial orientation plastic pipe through one-step method

A biaxially oriented, plastic pipe technology, applied in the field of polymer molding and processing, can solve the problems of high pipe scrap rate, large energy consumption, large floor space, etc., and achieve the effects of precise control, energy saving and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

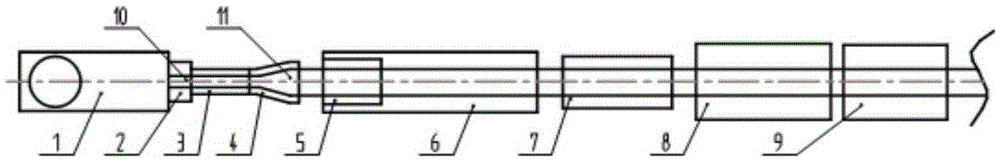

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings. The preferred embodiment of the invention is described in detail with reference to the accompanying drawings, wherein like reference numerals refer to like parts throughout.

[0016] Put the plastic raw material into the extruder 1, after melting and plasticizing in the extruder 1, extrude from the extrusion pipe die 2 behind the extruder 1 to form a tube embryo 10, and the tube embryo 10 passes through the tube embryo insulation section 3 Cooling and heat preservation in the high elastic state, heat preservation and heating to the stretchable temperature range of the high elastic state through the heating box in the biaxial stretching mold 4, under the traction force of the traction machine 7 and the adsorption force of vacuum, the tube embryo 10 The outer wall moves close to the inner wall of the biaxial stretching mold 4, realizing the radial and axial bidirectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com