Open type spinning device having coupling device used for supply conduit

A coupling device, an open technology, used in textiles and papermaking, continuous winding spinning machines, spinning machines, etc., can solve the problem of high cost and achieve the effect of sealing and good alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

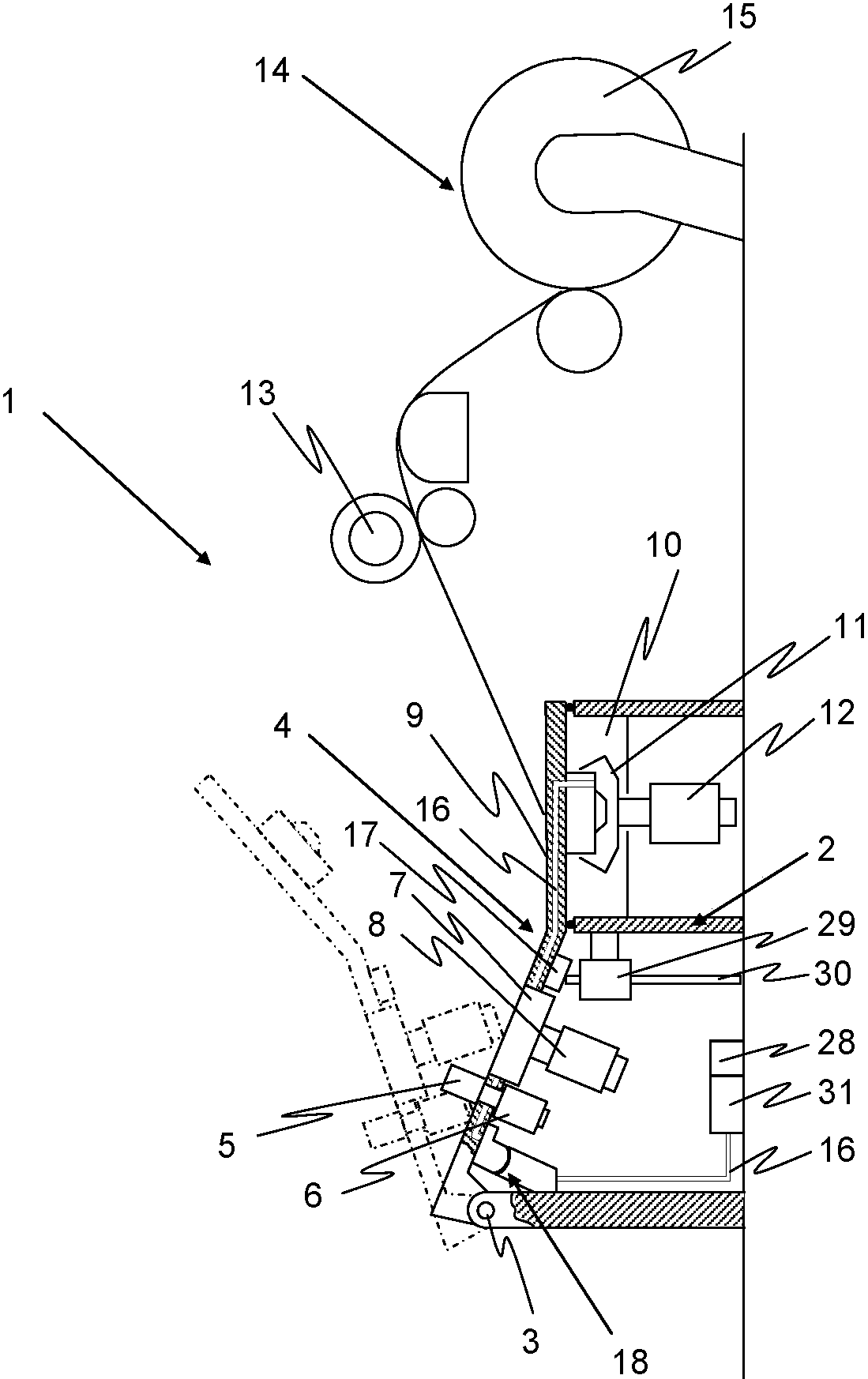

[0061] figure 1 A schematic sectional view of an open textile device 1 is shown. The open weaving device 1 here generally has different components or mechanisms for producing the yarn and comprises a feed device 5 and a carding device 7 through which fiber material (not shown) is drawn in and carded into The individual fibers are then supplied to a spinning rotor 11 in which the fiber material is spun into a yarn. In addition, a withdrawal device 13 and a winding device 14 are shown here, which are used to withdraw the spun yarn by means of which the finished yarn can be wound onto a bobbin 15 . The feed device 5 , the opening device 7 and the spinning rotor 11 are arranged here in the spinning box housing 2 , in which at the same time the rotor housing 10 for the spinning rotor 11 is also integrated.

[0062] According to this view, the essential components for producing the yarn are each driven by means of separate drives in order to form an essentially independent open we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com