Leather-like sheet and production method thereof

A kind of swatch and leather technology, applied in the field of napped leather swatches, the preparation of the above-mentioned leather swatches, can solve the problems of soft hand feeling and structural changes, etc., and achieve excellent stretchability and drape, good appearance, shape stability and shape Excellent recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

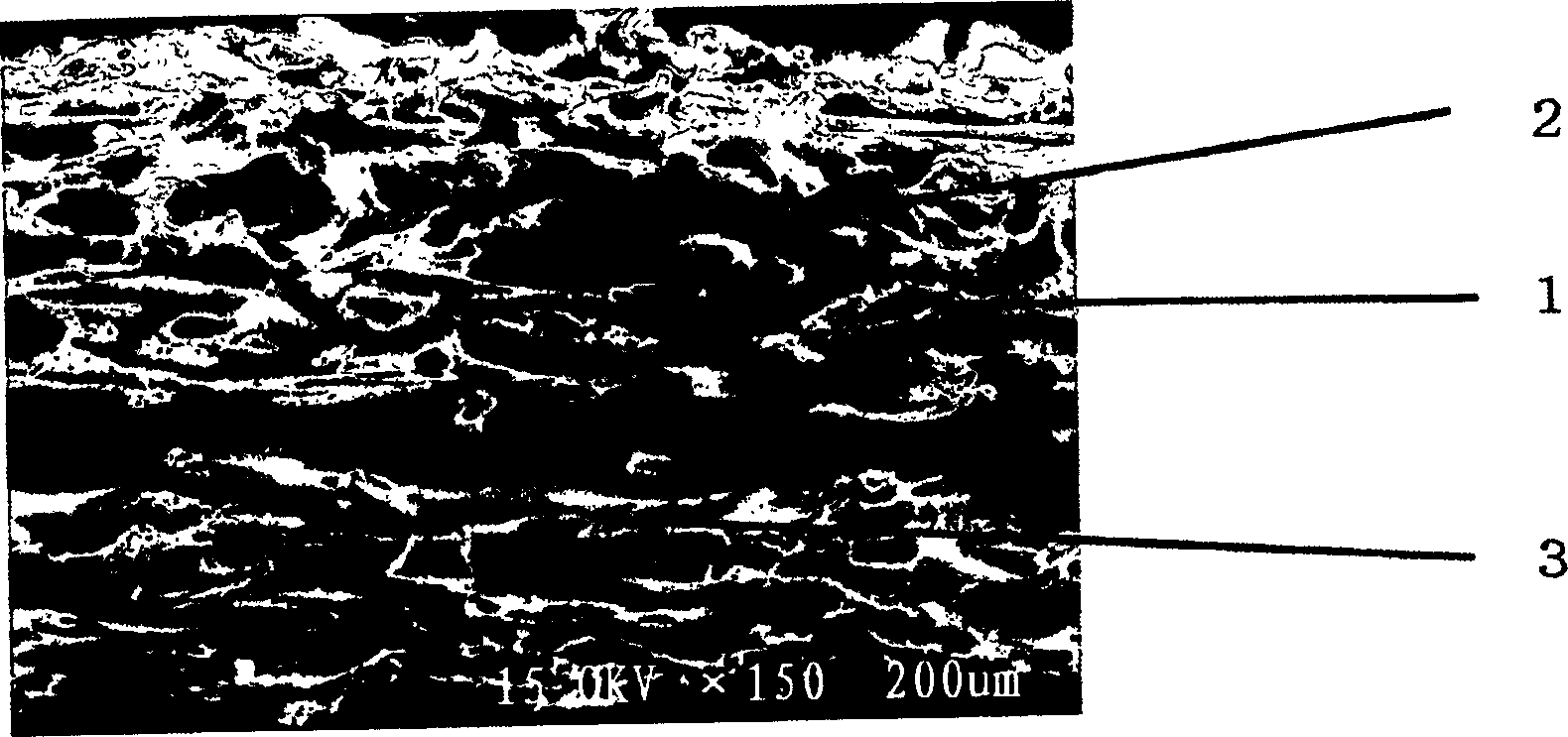

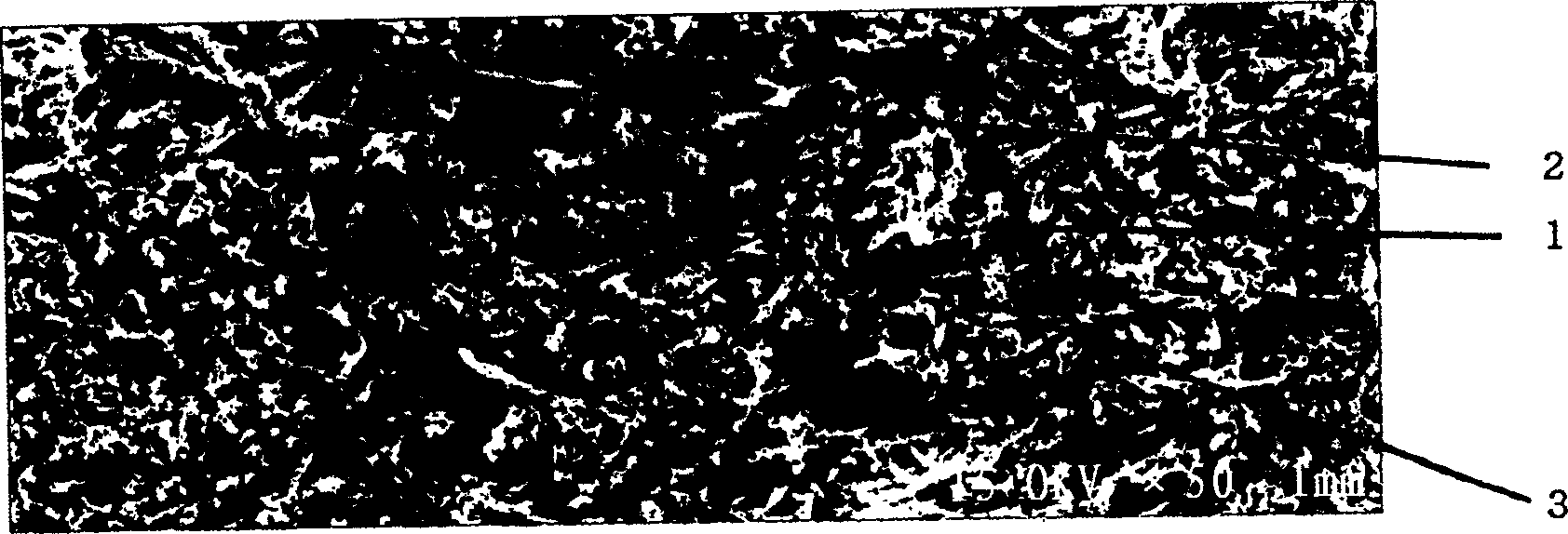

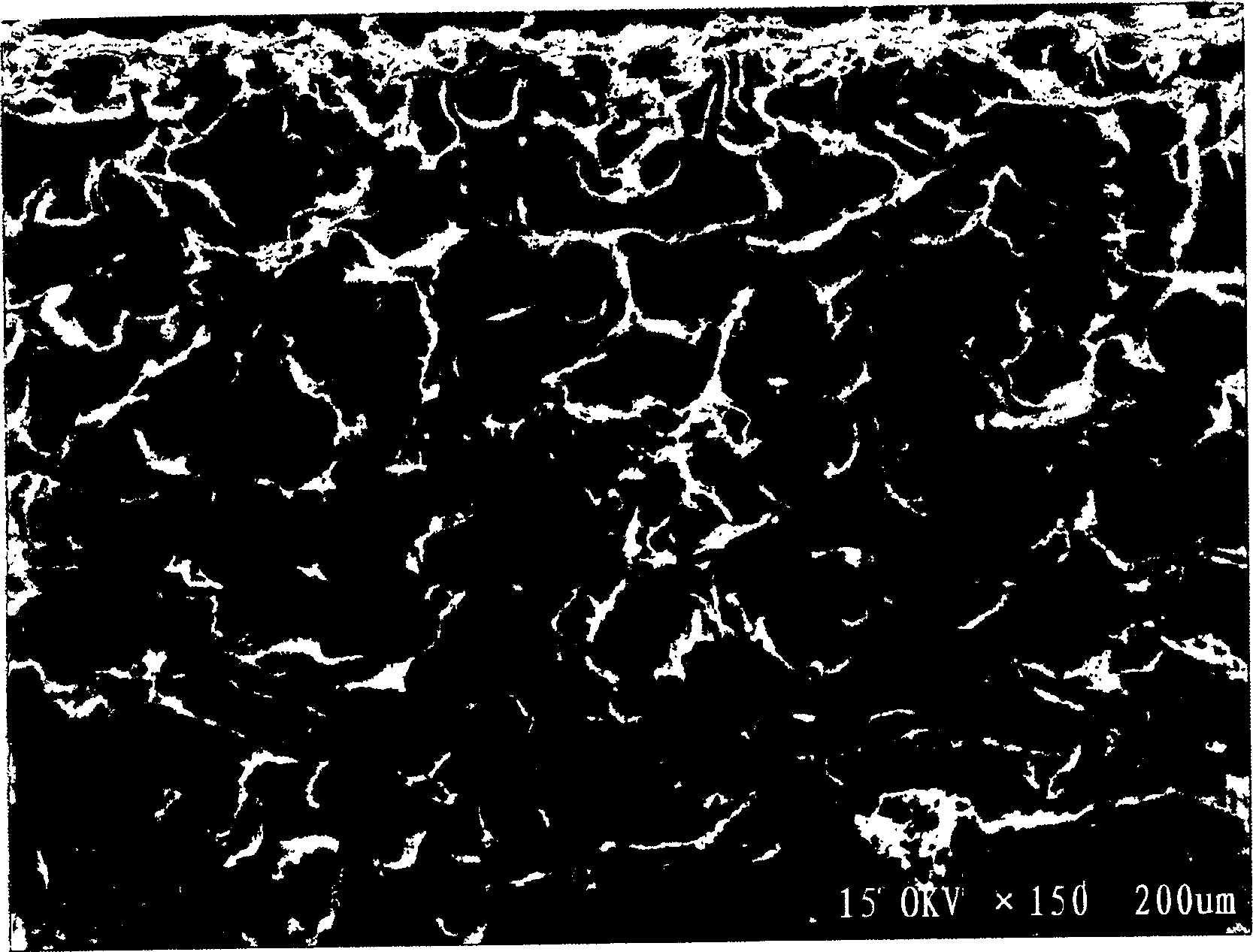

Image

Examples

Embodiment 1

[0070] Poly-3-methyl-1,5-pentane adipate glycol, 4,4'-diphenylmethane diisocyanate, polyethylene glycol and 1,4-butanediol with an average molecular weight of 2000, by The isocyanate was melt-polymerized with 43% nitrogen to obtain a polyester-based polyurethane. Melt viscosity 5000 poise. 50 parts of the above-mentioned polyester-based polyurethane powder (island component elastic polymer) and 50 parts of low-density polyethylene powder (sea component) having a dry moisture content of 50 ppm or less were melt-kneaded with a screw kneader at 230°C to obtain Sea-island type hybrid spun fibers with a melt spinning fineness of 14 dtex having polyurethane on a part of the surface (A 0 ). In addition, 50 parts of nylon-6 powder (island component inelastic polymer) and 50 parts of polyethylene powder (sea component) were melt-kneaded with a screw kneader, and then melt-spun at 280°C to obtain sea islands with a fineness of 10 dtex. Type blended spinning fiber (B 0 ). fiber (A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com