Making process of mold composite material tray

A technology of composite materials and manufacturing methods, which is applied in the field of composite material tray manufacturing, can solve the problems of plastic trays such as easy deformation, poor durability, and self-heavyness, and achieve the effect of overcoming perishable deterioration, easy deformation, and self-heaviness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

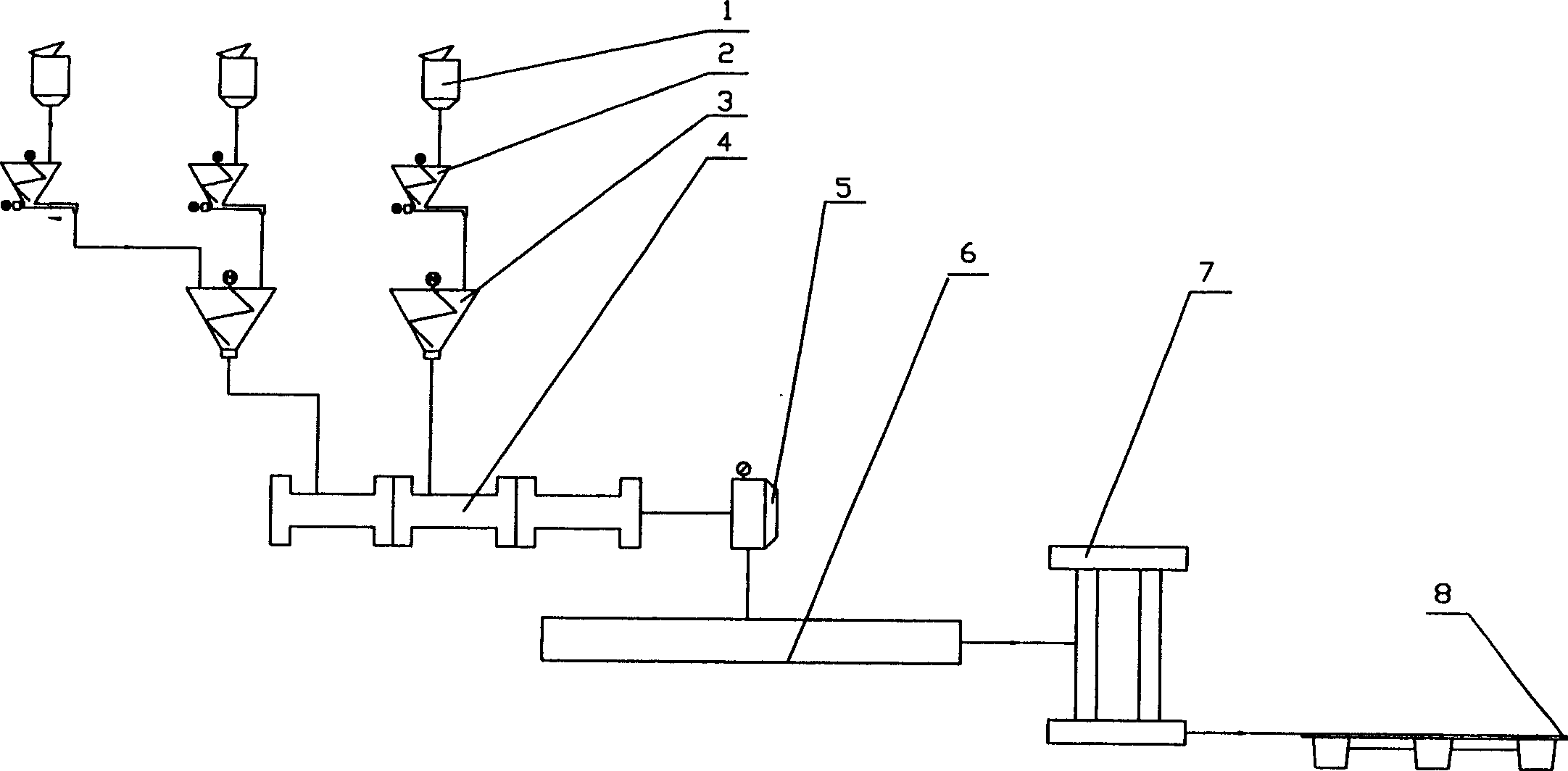

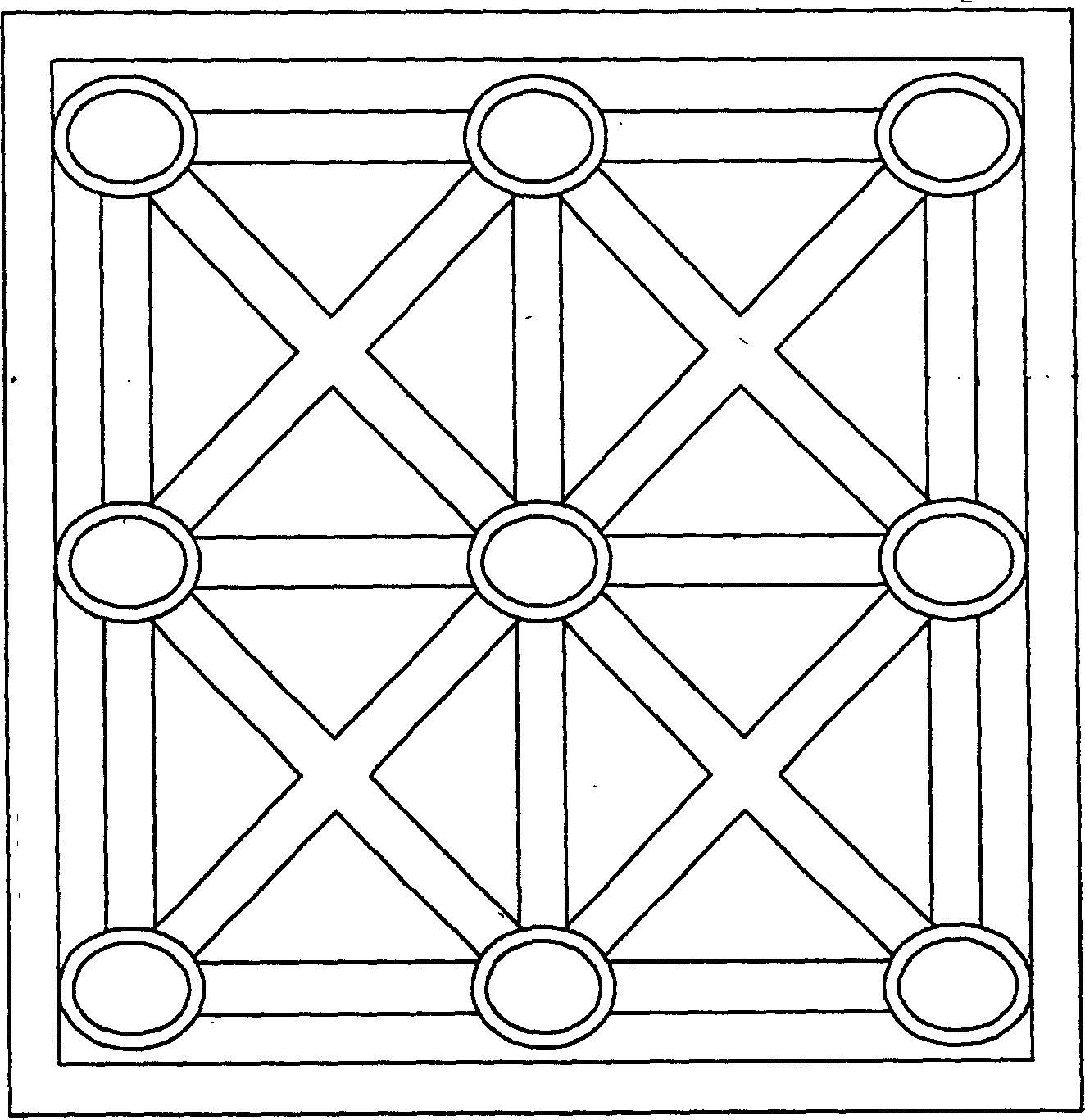

[0010] Such as figure 1 As shown, under the process conditions of molding temperature 80-140°C, pressure 200-500 tons, and holding time 2-6 minutes, plastics, wood chips, glass fibers, and polymer additives are measured from the stocker 1 through the weighing device 2, Enter the homogenizer 3 and the screw extruder 4 for further mixing and homogenization to form a uniform mixture, then measure 5, enter the mold 6 to lay layers, and press 7 for hot pressing, demoulding and trimming to form a product 8 (shape Such as figure 2 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com