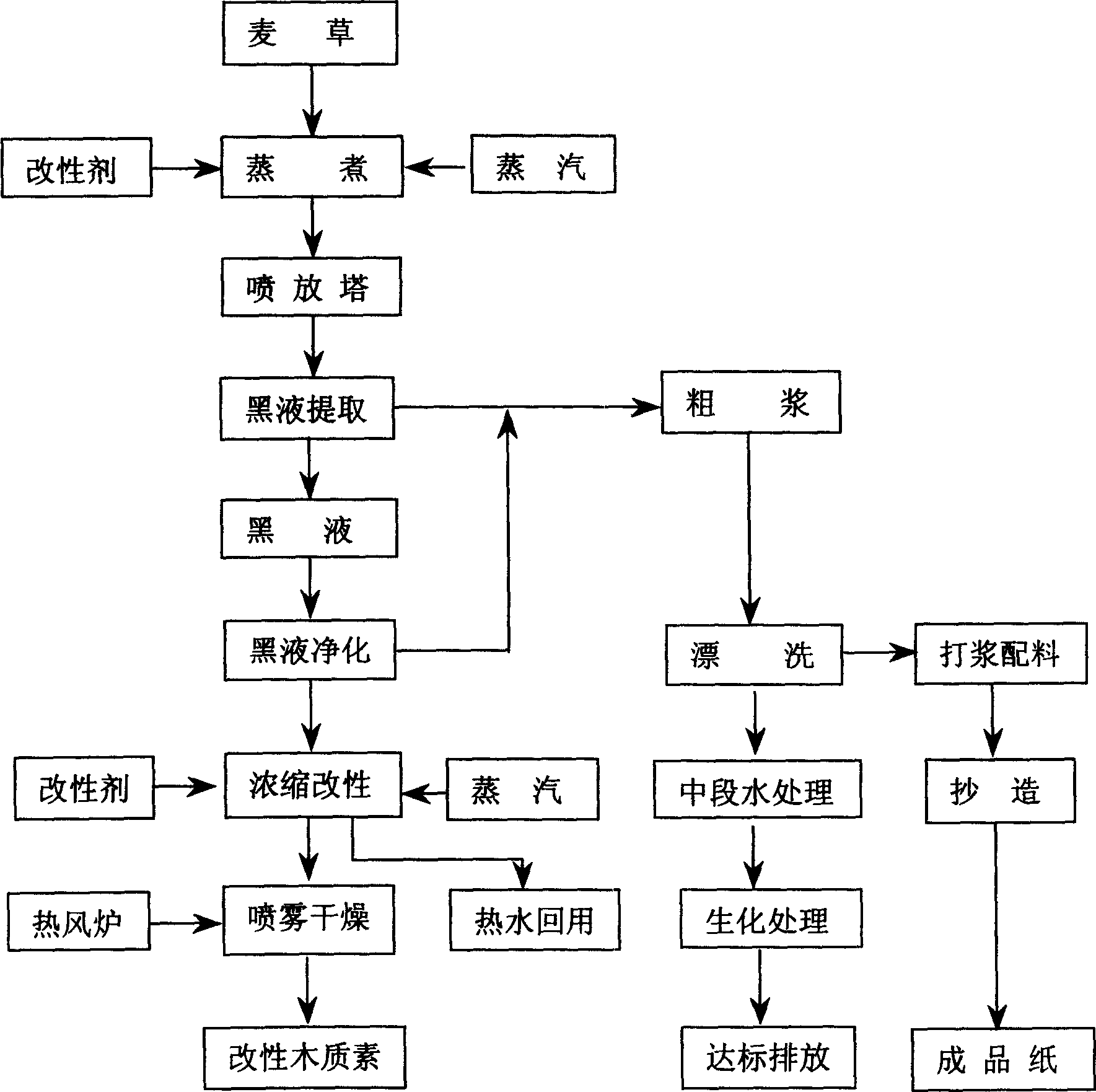

Cleaner production of paper by straw and lignin modification process

A clean production, agricultural and sideline product technology, applied in textiles and papermaking, chemical instruments and methods, paper, etc., can solve problems that do not meet the economic benefits pursued by enterprises, difficult to effectively combine environmental protection and production, low product quality and no way out, etc., to achieve The effect of enhancing the competitiveness of enterprises, reducing the trouble of concentrated scaling, and shortening the cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0014] Others are as in Example 1. When cooking and pulping wheat straw, the added cooking agent, modifier, molecular weight and performance regulator are caustic soda, dodecylaminobenzenesulfonic acid, polyoxyethylene ether, anthraquinone and its derivatives. substances, sodium sulfite, sodium formate, nitric acid, etc. The amount added is: 100 kg of caustic soda, 2.5 kg of dodecylaminobenzenesulfonic acid, 2.5 kg of polyoxyethylene ether, 5 kg of anthraquinone and its derivatives, 400 kg of sodium sulfite, and 8 kg of sodium formate. The modifiers added when the black liquor is concentrated by 30-50% are 200kg of acrylic acid and 100kg of chloroacetic acid. The cooking temperature is controlled at 160-170°C.

[0015] The lignin produced by this process can be used in cement admixtures, coal water slurry additives, windbreak and sand fixation agents, oil production aids, pesticide dispersants, etc., with remarkable economic, social and environmental benefits, and a good real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com