Bucket type closed steel smelting furnace

A steel-making furnace and barrel-type technology, which is applied in the field of barrel-type closed-chamber steel-making furnaces, can solve the problems of poor environmental protection, complicated procedures, and low thermal efficiency, and achieve the effects of large recovery, reduced environmental pollution, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

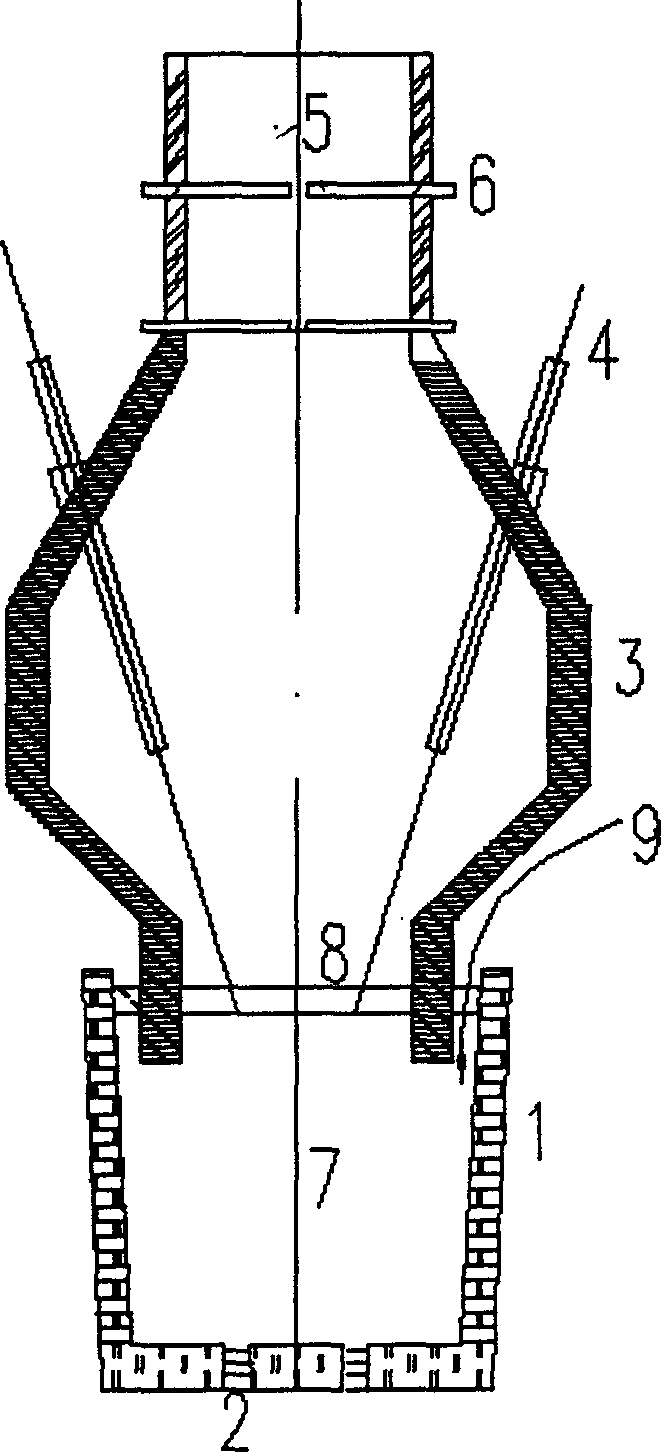

[0009] Barrel-type closed-chamber steelmaking furnace, the steel ladle is equipped with several argon or nitrogen gas-permeable bricks, and the upper edge is provided with a slag flow tank. The ladle is equipped with a lifting and lowering mechanism for receiving and transporting molten iron for blowing and transporting molten steel for refining or continuous casting.

[0010] The lower part of the plug-in furnace is straight cylindrical, both inside and outside are protected by refractory materials, and is used to insert molten steel for blowing; the middle part is determined according to the design principle of the top-bottom composite blowing converter, and its upper part is connected with the scrap steel preheating furnace body to Prevent air leaks. The function of the furnace is to provide a reaction space for the foamed molten steel and slag; there is a gap of 100-500 mm between the furnace and the ladle, and standing on the working platform around the furnace can contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com