Solid state polymerization preparation method of liquid crystal copolyester

A solid-state polymerization and copolyester technology, applied in liquid crystal materials, chemical instruments and methods, etc., to achieve the effects of easy control of reaction conditions, improved quality, and reduced equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]This example illustrates the method for solid-state polymerization of poly(p-hydroxybenzoic acid\2,6-naphthalene dicarboxylic acid\terephthalic acid\hydroquinone) liquid crystal copolyester prepolymer according to the present invention. The molar ratio of p-hydroxybenzoic acid (HBA), 2,6-naphthalene dicarboxylic acid (NDA), hydroquinone (HQ) and terephthalic acid (TA) in the prepolymer is 50 / 25 / 15 / 10 , the I.V. of the prepolymer is 1.5dL / g, the melting point is 312.4°C, and the particle diameter is 1.1mm. After vacuum-drying the prepolymer at 110°C for 4 hours, take 10 g and place it in a tubular solid-state polymerization device, blow in nitrogen, raise the temperature to 300°C at a rate of 3°C / min, and then start the solid-state polymerization of the prepolymer. After reaching the set polymerization time, the solid-state polymerization device was cooled to room temperature in air under the condition of blowing nitrogen. In this embodiment, the flow rate of nitrogen ga...

Embodiment 2

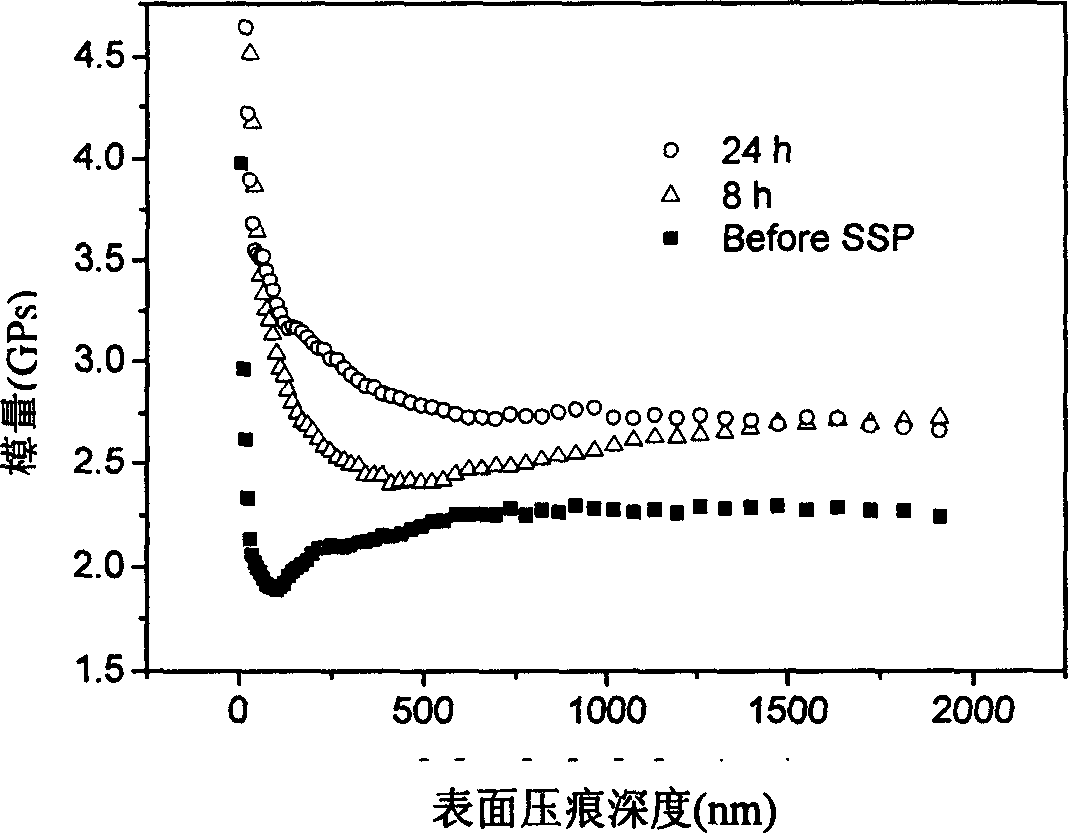

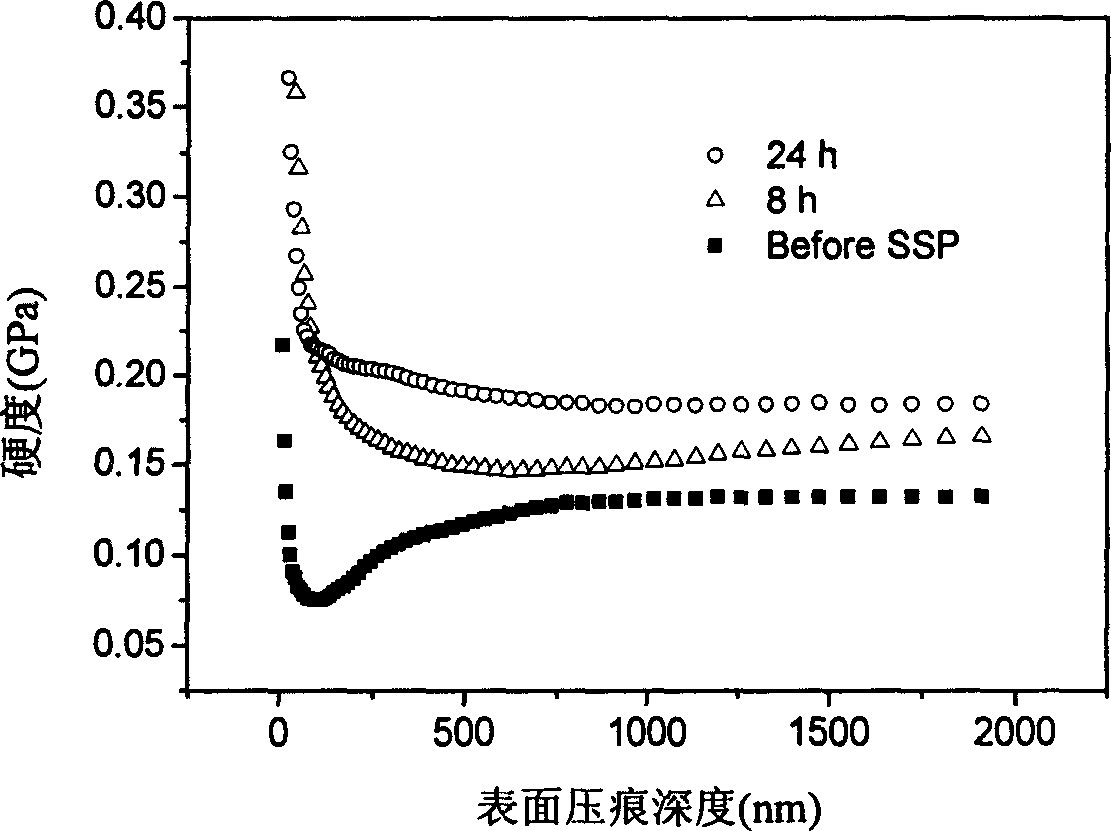

[0037] The experimental method is the same as in Example 1, but the solid state polymerization reaction temperature of this example is 280°C. Table 2 lists the melting points of polymer products after solid-state polymerization at different times under this temperature condition. The prepolymer and the products of solid state polymerization reaction for 8 hours and 24 hours were subjected to nanoindentation test, and the test results are shown in Table 3 and attached figure 1 , 2 .

[0038] Polymerization time (h)

[0039]

[0040] This embodiment shows that the solid-state polymerization method of the present invention can significantly improve the molecular weight of poly(p-hydroxybenzoic acid\2,6-naphthalene dicarboxylic acid\terephthalic acid\hydroquinone) liquid crystal copolyester, and its mechanical properties Properties (hardness and modulus) are also greatly improved.

Embodiment 3、4

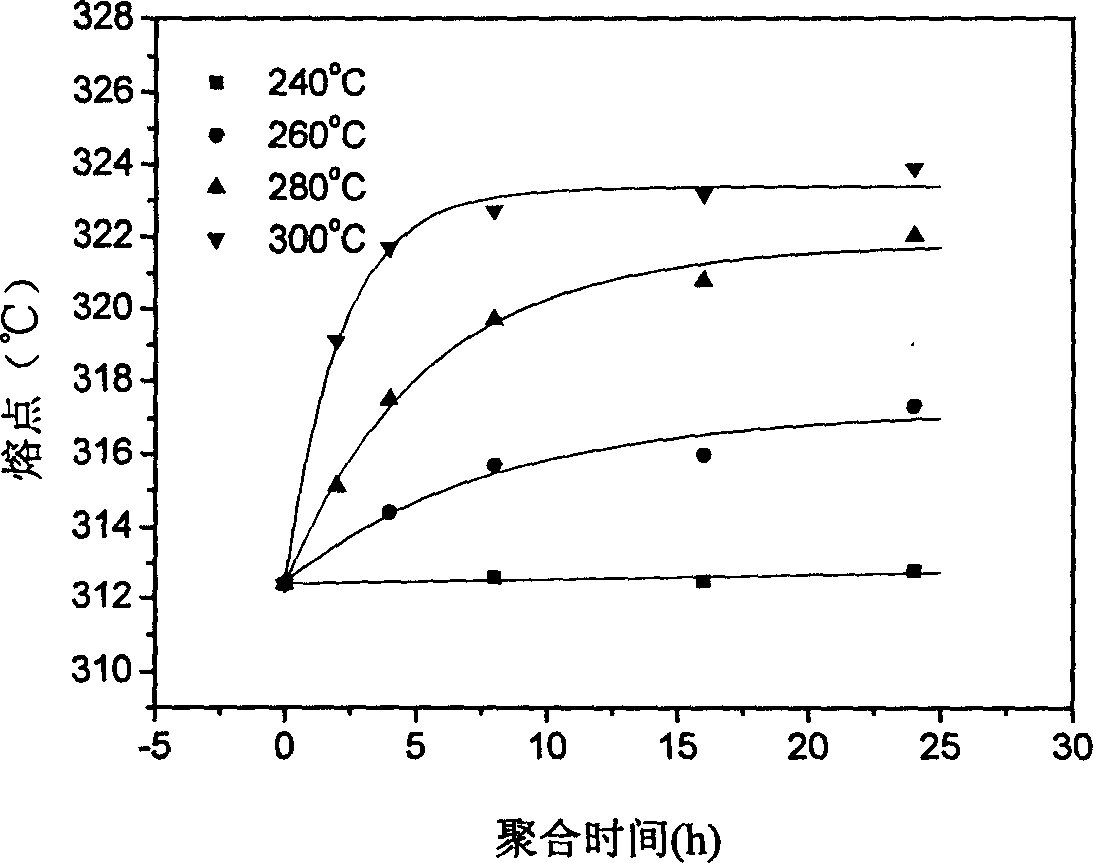

[0042] Experimental method is the same as embodiment 1. The change of the melting point of the polymerization product was investigated at 240℃ and 260℃ for solid-state polymerization. Together with Examples 1 and 2, under four different solid-state polymerization temperatures, the change of polymer melting point with solid-state polymerization time is shown in the appended image 3 middle. Depend on image 3 It can be seen that the melting point of the reaction at 240°C has not changed. With the increase of the solid-state polymerization temperature, the reaction rate increases, and the time required to reach the expected melting point product is shortened, so the melting point of the product rises rapidly. It can be seen that the temperature range for the solid-state polymerization of the prepolymer is 260-300°C, and 280-300°C is more suitable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com