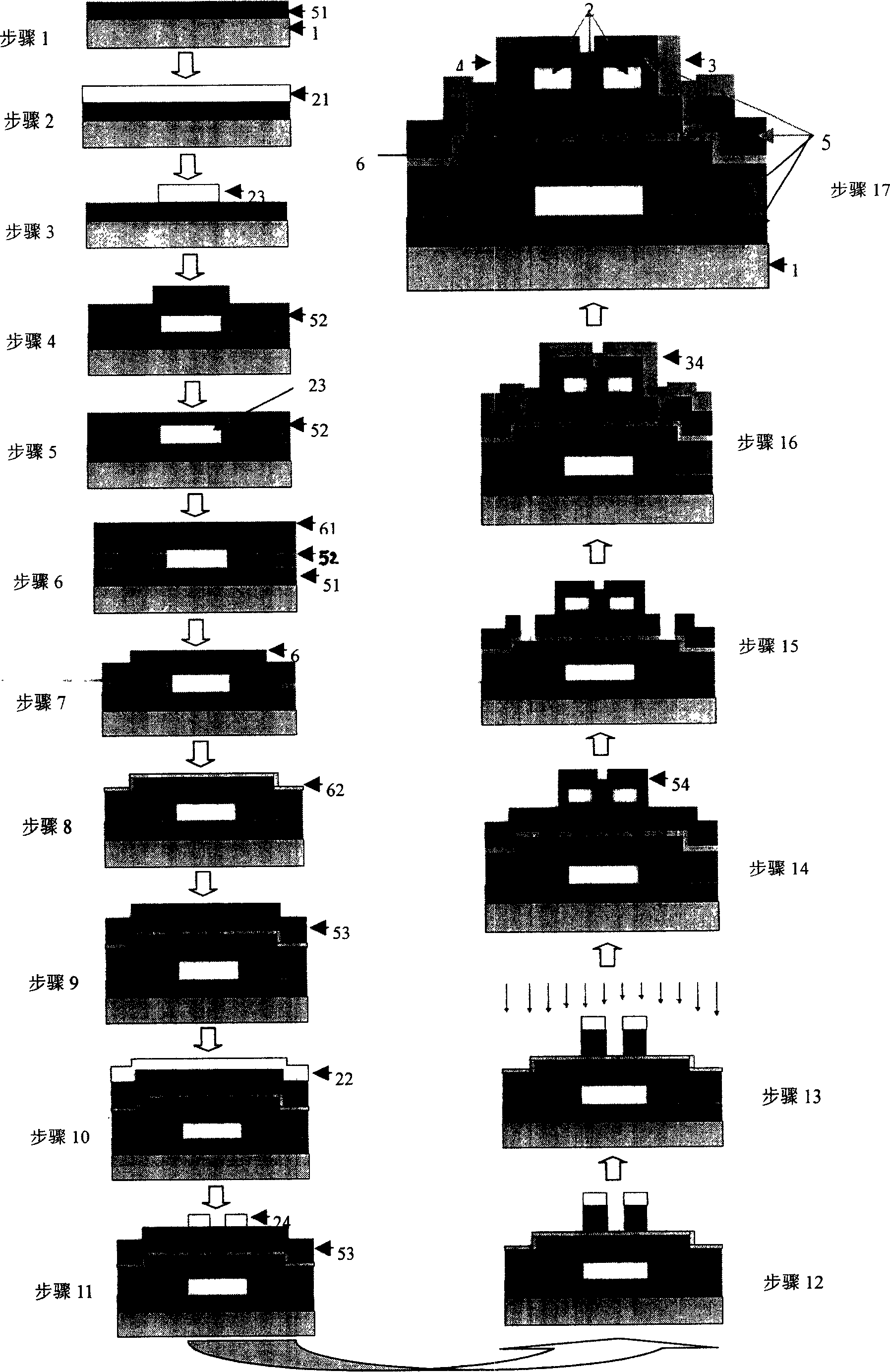

Polycrystalline SiTFT of multi-grid double-channel structure

A polysilicon thin film, dual-channel technology, applied in transistors and other directions, can solve problems such as increasing the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0048] 1) First, use PECVD method on the silicon substrate at 300°C to obtain 5000 Å of SiO 2 .

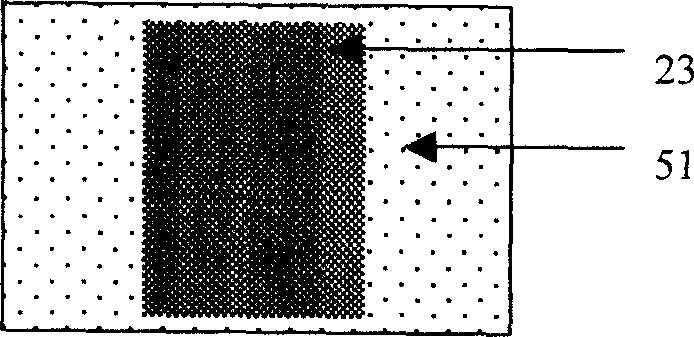

[0049] 2) Use LPCVD method on the substrate (atmospheric pressure 0.3Torr, SiH 4 60 sccm, the speed is 25 Å per second) to deposit 2000 Å of a-Si (amorphous silicon, SiH 4 Decomposed as a gas source to obtain a-Si, the substrate temperature during deposition is 200°C, and the background vacuum is 2×10 -4 Pa, reaction chamber pressure 80Pa) and ion implantation doping (energy 45KeV, concentration 5×10 15 cm -2 ), then use plasma etching process (dry etching) photolithography such as figure 2 The pattern shown forms the bottom gate 23;

[0050] 3) Precipitate 2500 Å of SiNx as the insulating layer of the bottom gate. The growth of this layer of film is also performed on SiH by PECVD 4 and NH 3 grow under a mixed atmosphere, the substrate temperature is kept at 270°C, and the reaction chamber pressure is 30Pa;

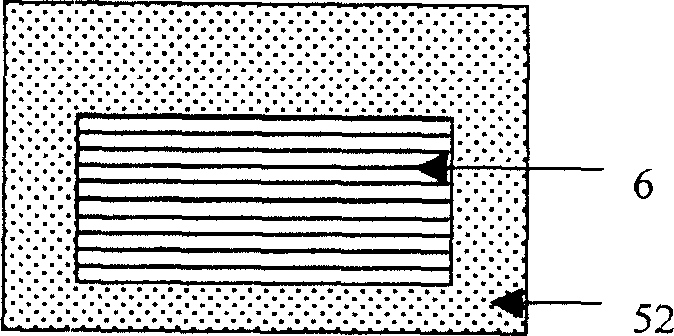

[0051] 4) Precipitating a 500 Å a-Si thin film by LPCVD technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com