Micro-liquid extracting method and apparatus on micro-analytic chip

A micro-analysis and extraction technology, which is applied in separation methods, analysis materials, solvent extraction, etc., can solve the problems of low concentration ratio and no application of microfluidic chips, and achieve simple channel configuration, easy operation, and chip structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

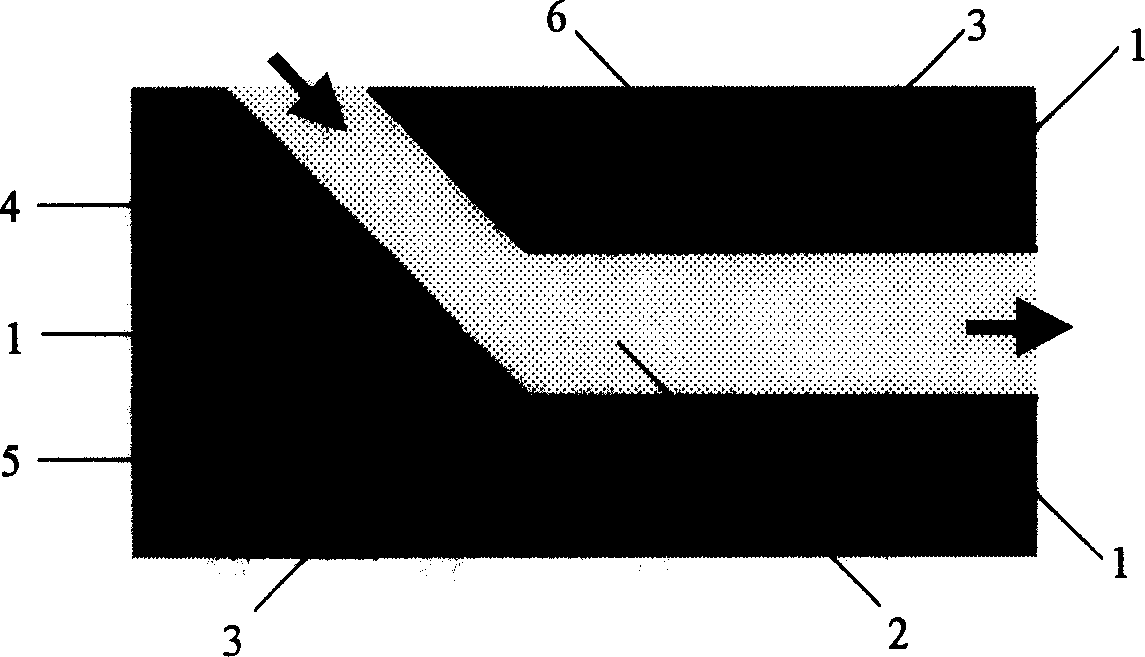

[0032] Reference figure 1 . Is a top view of a preferred embodiment 1 according to the present invention. The chip 1 channel configuration is a Y-shaped structure. The flowing liquid phase 2, the channel 4 and the fixed liquid phase 3, and the channel 5 present a cross-converging channel configuration, and a microstructure 6 that traps the fixed liquid phase 3 is processed on the flowing liquid phase channel 4 and the side walls. The fixed liquid phase 3 flow is introduced by the fixed liquid phase channel 5, and the mobile liquid phase 2 is introduced by the mobile liquid phase channel 4. During extraction, a certain volume of the fixed liquid phase 3 is trapped in the microstructure 6, or the flow of the fixed liquid phase 3 is stopped, and a fixed liquid phase 3 and a mobile liquid phase 2 are formed at the outlet of the fixed liquid phase channel 5. Interface; mobile liquid phase 2 maintains a flowing state, and the thick arrow indicates the flow direction of the mobile liqui...

Embodiment 2

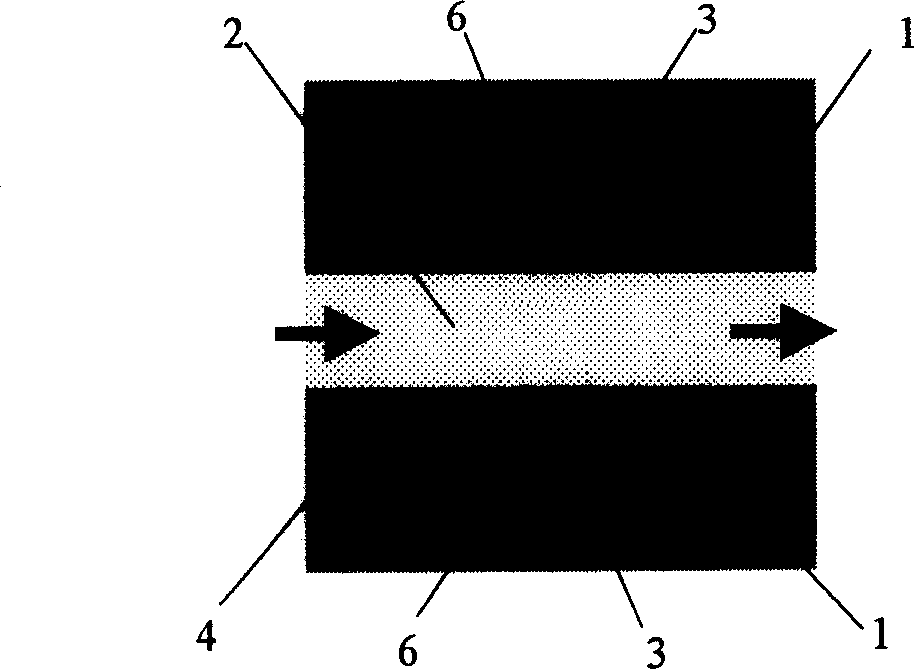

[0039] Refer to figure 2 Among them, two different configurations of concave microstructures 6 for trapping the fixed liquid phase 3 are processed on the sidewalls of the flowing liquid phase 2 channel 4 of the chip 1, and the sidewall microstructures 6 on the channel in the figure are rectangular structures; The sidewall microstructure 6 under the channel is a narrowed structure, which is beneficial to form a stable and reproducible interface between phases. When the extraction is in progress, a certain volume of the fixed liquid phase 3 is trapped in the microstructure 6, and the mobile liquid phase 2 remains in a flowing state, and the thick arrow indicates the flow direction of the mobile liquid phase.

Embodiment 3

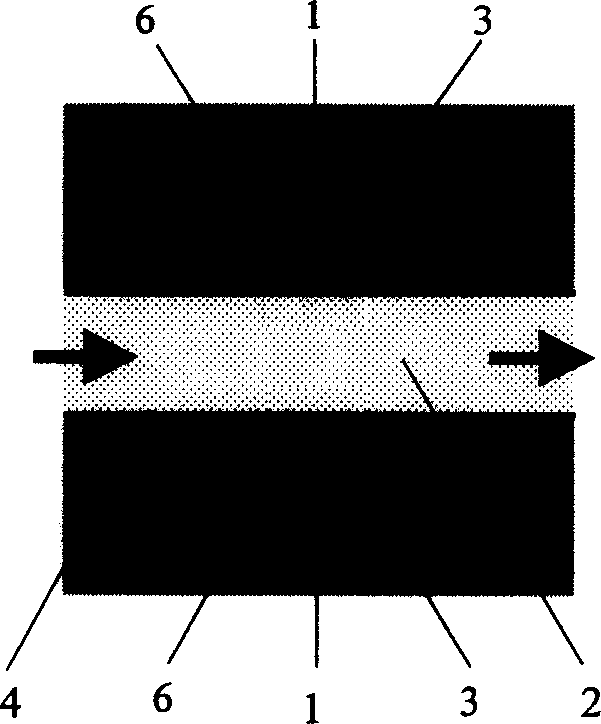

[0041] Refer to image 3 Among them, two other concave microstructures 6 with different configurations for trapping the fixed liquid phase 3 are processed on the sidewalls of the flowing liquid phase 2 of the channel 4 of the chip 1. The sidewall microstructures 6 on the channel in the figure are divided into four parts. The third round structure; the microstructure 6 of the lower side wall of the channel is a constricted triangular structure, and the use of constriction is conducive to forming a stable and reproducible interface between phases. When the extraction is in progress, a certain volume of the fixed liquid phase 3 is trapped in the microstructure 6, and the mobile liquid phase 2 remains in a flowing state, and the thick arrow indicates the flow direction of the mobile liquid phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com