Carboxyl functional polymer/SiO2 composite nanometer particle and preparing method thereof

A functional polymer technology, applied in the field of polymer materials, carboxyl functional polymer/SiO2 composite nanoparticles and its preparation, can solve the problem that the coating layer is easy to fall off, so as to solve the problem of grafting rate and grafting efficiency Low, expand the application value, expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

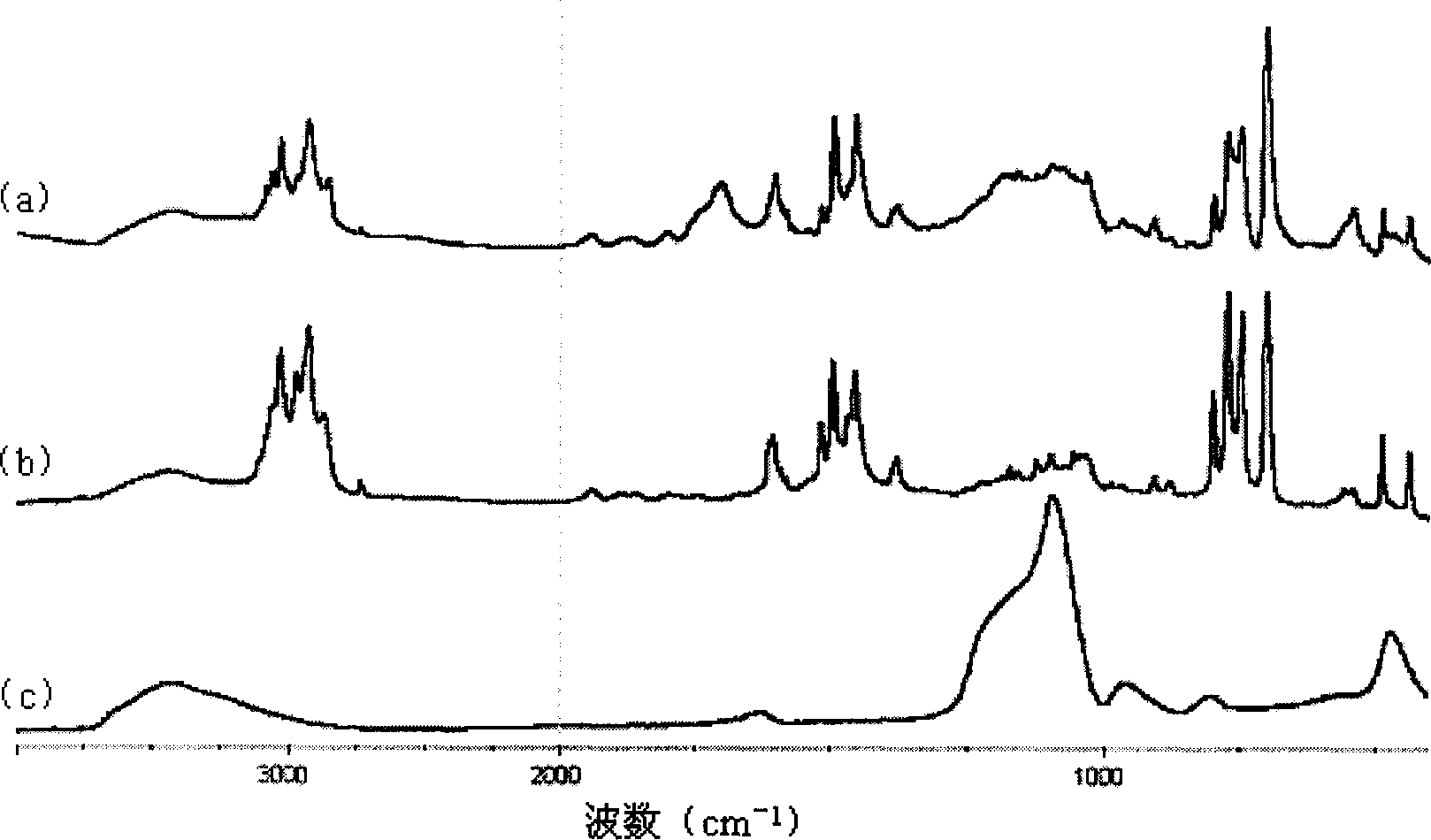

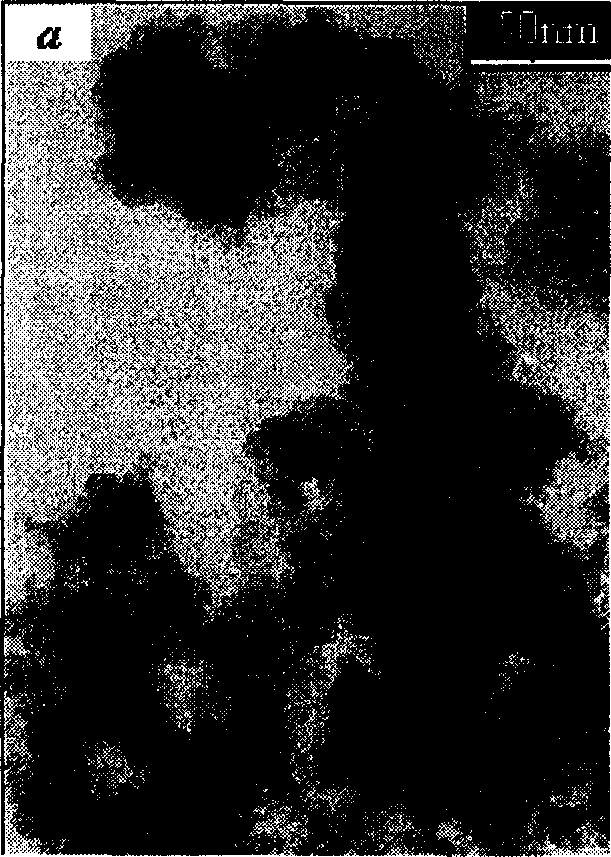

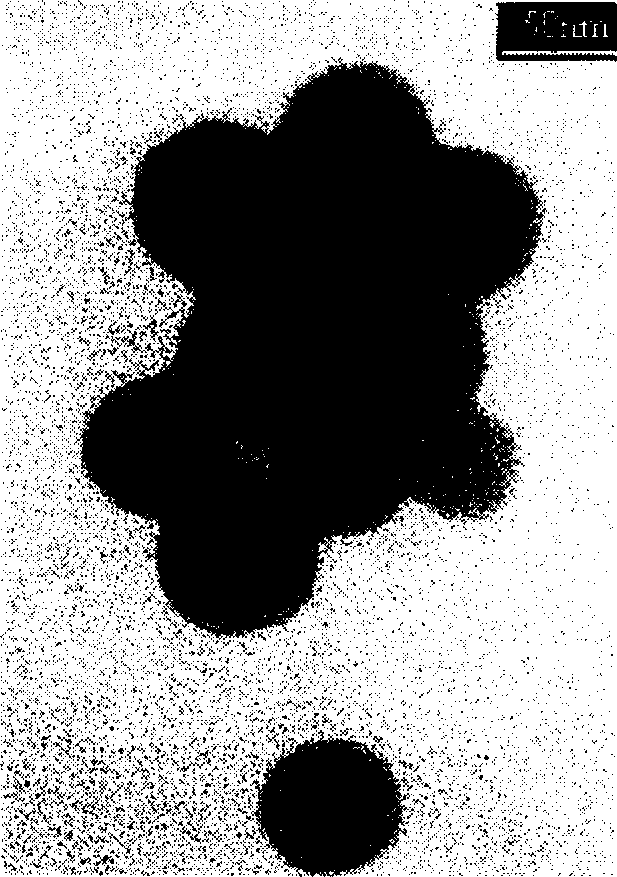

Image

Examples

Embodiment 1

[0058] Embodiment 1: the average particle diameter is 10 ± 5nm, and the specific surface area is 640m 2 / g nano-SiO 2 After being treated with 5wt% KH-570 silane coupling agent, weigh 4 parts and add it to 100 parts of styrene monomer, stir and ultrasonically disperse evenly. Add 370 parts of deionized water, 6 parts of sodium dodecylsulfonate and 0.75 part of nonylphenol polyoxyethylene ether (10) in the four-necked bottle equipped with mechanical stirring, reflux condenser, nitrogen protection and thermometer, and heat up After reaching 40°C and stirring to dissolve, add monomer and SiO at 50°C 2 mixture. Then, add 70% of the initiator aqueous solution made up of 0.5 parts of ammonium persulfate and 75 parts of deionized water, raise the temperature to 82 ° C for 1 hour, add 10 parts of sodium bicarbonate, and then add 1 drop of sodium bicarbonate in 5 seconds. Add 10 parts of methacrylic acid (MAA) dropwise at a high speed. After the dropwise addition, the reaction was ...

Embodiment 2

[0059] Embodiment 2: SiO 2 The addition amount of the compound is reduced from 4 parts to 0.1 part, and the KH-570 consumption is 1.5wt%, and the MAA addition amount is changed into 0.1 part simultaneously, and the buffering agent consumption is changed into 0.1 part, and all the other formulations are the same as Example 1. Monomer and SiO 2 The mixture was added to the system at 50°C, the reaction was carried out at 60°C for 8 hours, and MAA was added dropwise. The yield, grafting rate and grafting efficiency of the obtained product are 97.4%, 98325% and 98.3% respectively, and the particle size distribution is 60-70nm.

Embodiment 3

[0060] Embodiment 3: SiO 2 The addition of the compound increases to 40 parts by 4 parts, and the consumption of KH-570 is 30wt%, buffering agent changes 5 parts of sodium hydroxide into, and all the other formulas are identical with example 1. The MAA was reacted for 3 hours after the dropwise addition was completed. The yield, grafting rate and grafting efficiency of the obtained product are 89.7%, 254% and 92.1% respectively, and the particle size distribution is 60-70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com