New technology for flashing speed activation flotation of Carin type gold mine

A new process, Carlin-type technology, applied in flotation, solid separation, grain processing, etc., can solve the problems of no substantial progress and poor flotation effect, and reduce the flotation operation and the total recovery rate of gold selection. The effect of improving and promoting the differentiation of medium and ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

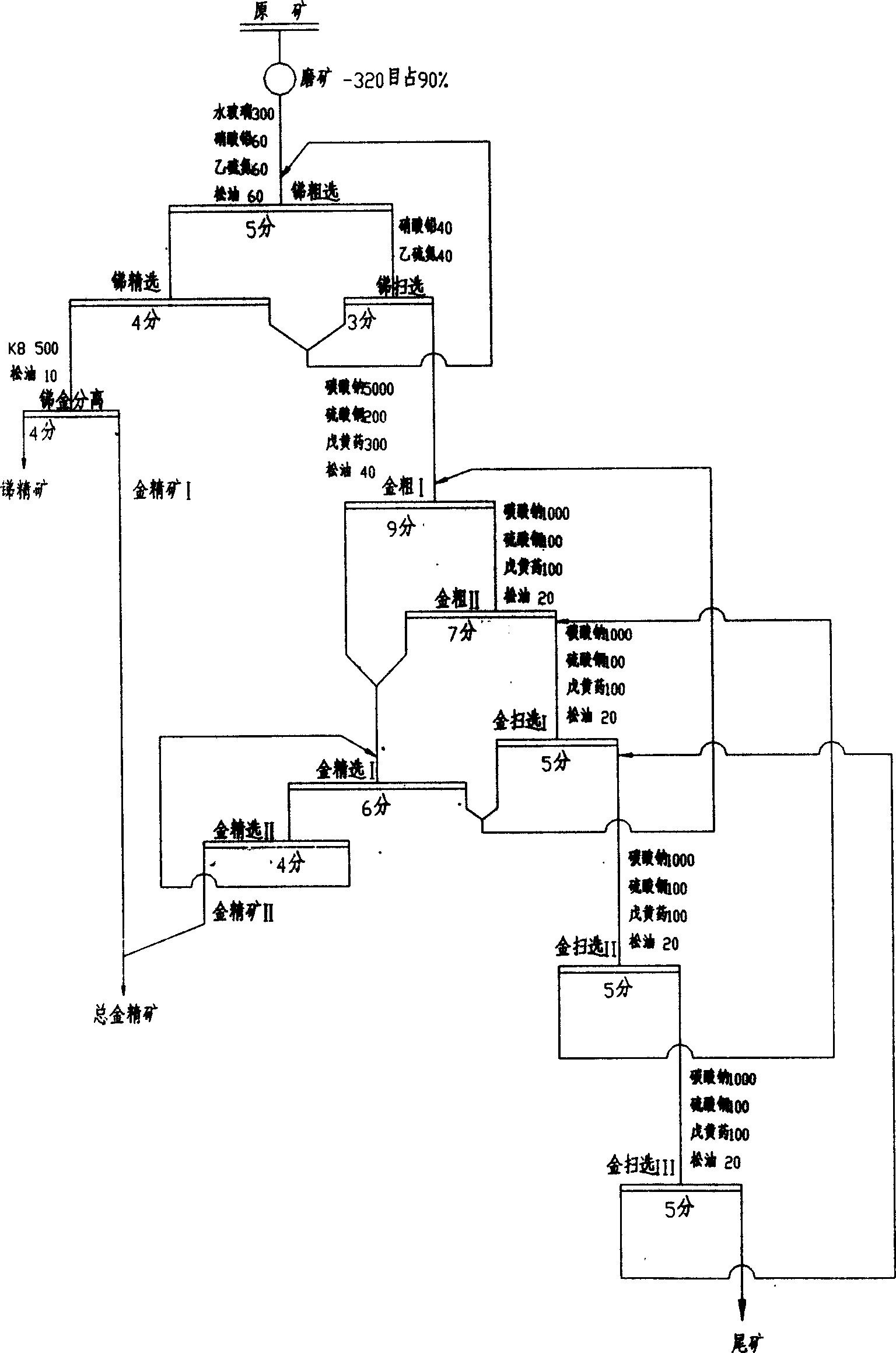

[0010] Conventional flotation process test, that is, sodium carbonate is not added to the mill, but only added to the flotation machine. For details of its process conditions, see figure 1 .

[0011] Put 500g of Carlin-type gold ore containing 4.8g / t of gold into the laboratory-type grinding machine, the size of the grinding machine is Φ200×240mm, the grinding concentration is 60%, the grinding time is 8 minutes, and the grinding fineness reaches- 43μm (-320 mesh) accounts for 90%. A laboratory-type flotation machine with a specification of 1.5 liters is used to stir the finely ground pulp while adding water glass 300g / t and sodium carbonate 5000+1000+1000+1000 in sequence. +1000g / t, copper sulfate 200+100+100+100+100g / t, pentaxanthate 300+100+100+100+100g / t and pine oil 40+20+20+20+20g / t for rough selection 2 times and 3 times of sweeping, the cumulative time is 31 minutes, 2 times of selection in 0.75 liter and 0.5 liter flotation machines, the time is 10 minutes, and 35.2...

Embodiment 2

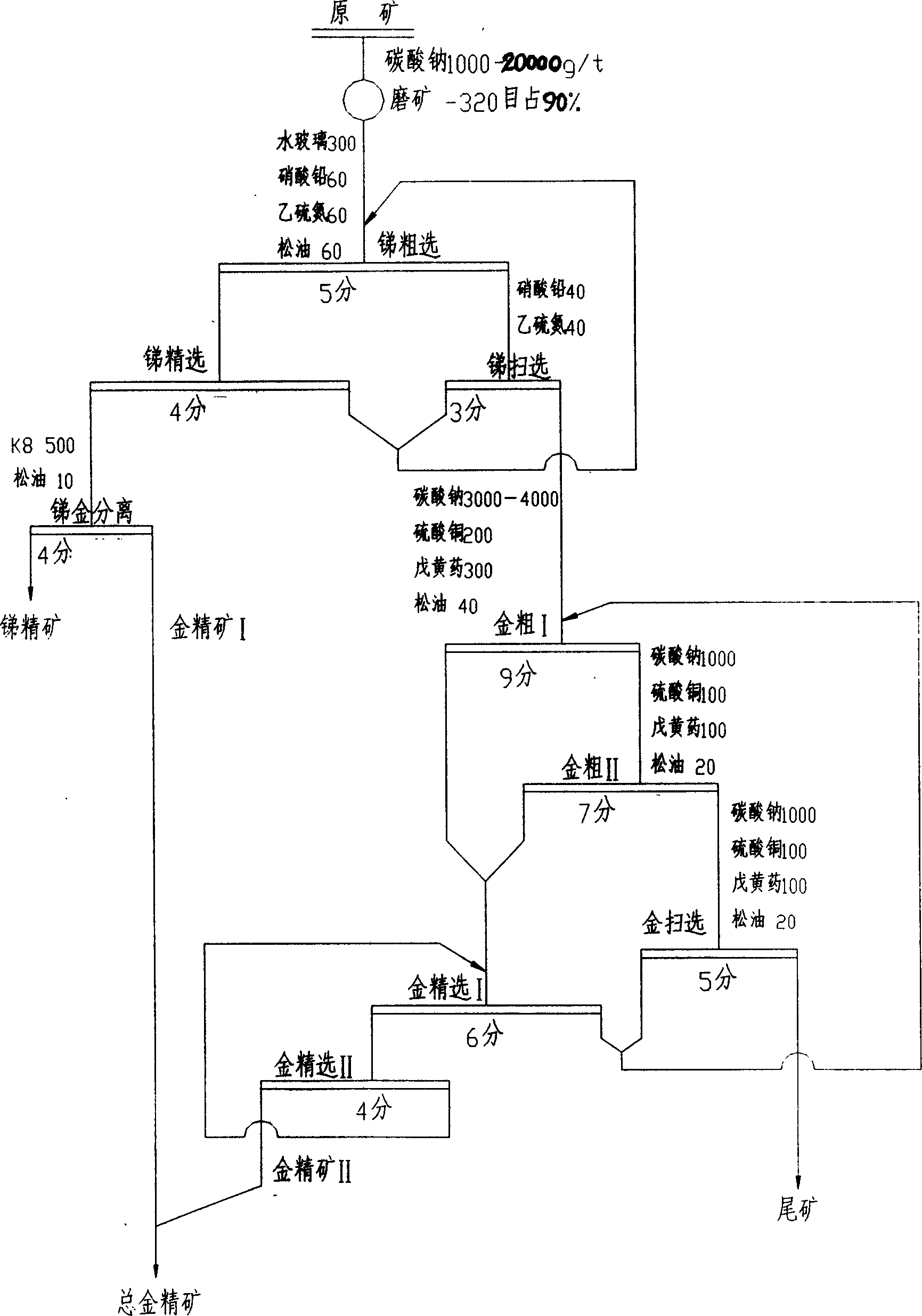

[0013] For flash activation flotation new process test, 1000g / t of sodium carbonate is added to the mill in advance. For details of its process conditions, see figure 2 .

[0014] Put 500g of gold-bearing 4.8g / t Carlin-type gold ore and 0.5g of sodium carbonate into the laboratory-type grinding machine, the size of the grinding machine is Φ200×240mm, the grinding concentration is 60%, the grinding time is 8 minutes, and the grinding The ore fineness reaches -43μm, accounting for 90%. The ground pulp is stirred by a laboratory-type flotation machine with a specification of 1.5 liters, and at the same time, 300g / t of water glass and 4000+1000+1000g / t of sodium carbonate are added in sequence. , copper sulfate 200+100+100g / t, pentaxanthate 300+100+100g / t and pine oil 40+20+20g / t roughing twice and sweeping once, the cumulative time is 21 minutes, at 0.75 liter and a 0.5-liter flotation machine for 2 times for 10 minutes to obtain 37.6 g of gold concentrate with a gold content ...

Embodiment 3

[0016] For flash activation flotation new process test, 1500g / t of sodium carbonate was added to the mill in advance. For details of its process conditions, see figure 2 .

[0017] Put 500g of ore containing 4.9g / t of gold and 0.75g of sodium carbonate into the laboratory-type grinding machine, the size of the grinding machine is Φ200×240mm, the grinding concentration is 60%, the grinding time is 8 minutes, and the grinding fineness reaches- 43μm accounts for 90%. The ground pulp is stirred by a laboratory-type flotation machine with a specification of 1.5 liters. At the same time, 300g / t of water glass, 3500+1000+1000g / t of sodium carbonate, and 200+ of copper sulfate are added in sequence. 100+100g / t, pentaxanthate 300+100+100g / t and pine oil 40+20+20g / t roughing and sweeping for 21 minutes, 2 times of refining in 0.75L and 0.5L flotation machines , the time is 10 minutes, 39.4g of gold concentrate containing 50.6g / t of gold is obtained, and the recovery rate is 81.37%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com