Treatment method of offshore oil drilling wastewater

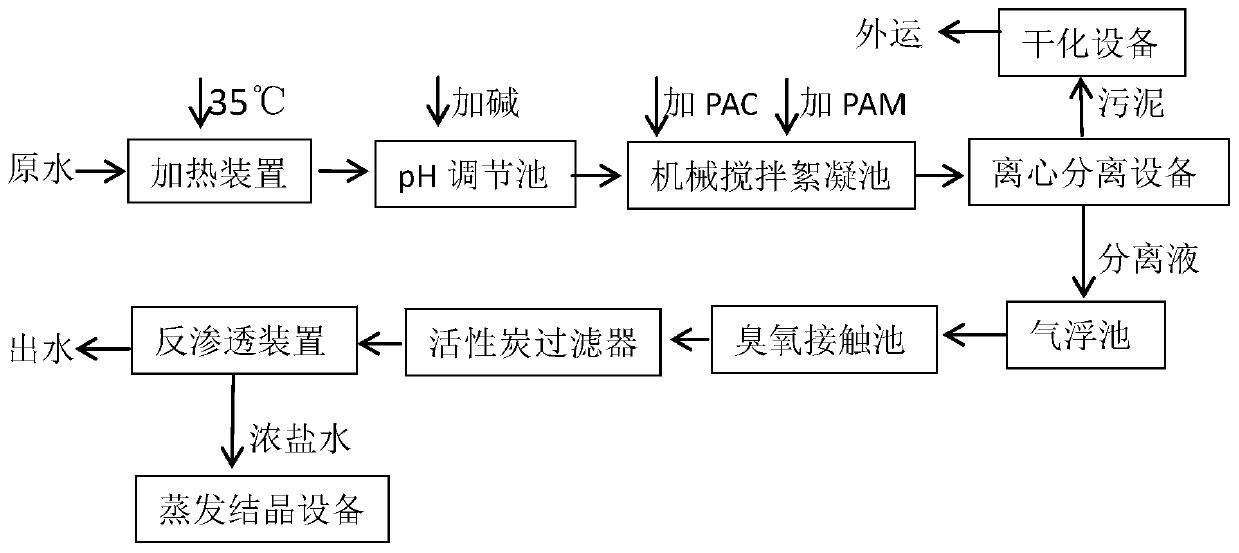

A treatment method, offshore oil technology, which is applied in the field of offshore oil drilling wastewater treatment, can solve problems such as inability to meet wastewater discharge requirements, achieve good treatment effects, increase floating speed, and reduce oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

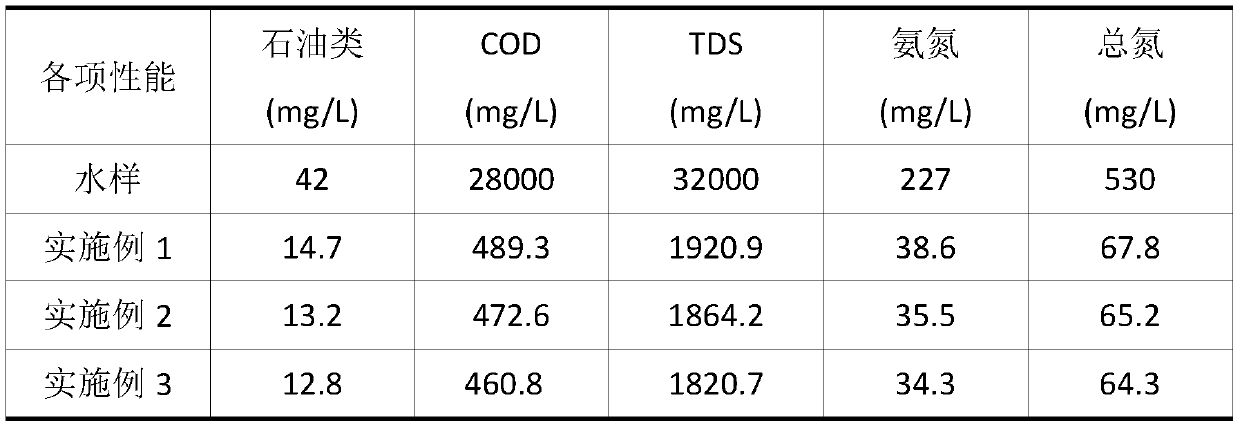

Embodiment 1

[0019] A treatment method for offshore oil drilling waste water, comprising the following steps:

[0020] (1) Heat the drilling wastewater to 30°C for physical demulsification, and the reaction time is 2 minutes to precipitate the dissolved impurities in the wastewater.

[0021] (2) Add NaOH to the heated wastewater to adjust the pH of the wastewater to 9. Then the waste water enters the mechanically stirred flocculation tank, and polyaluminum chloride (PAC) 100mg / L is added to the first cell, the stirring time is 60s, and the stirring speed is 60r / min, so that the coagulant is fully mixed and the impurities in the water are destabilized. The stirring time of two grids is 20min, and the stirring speed is 15r / min, so that the impurities in the wastewater are coagulated and flocculated. Add polyacrylamide (PAM) 15mg / L to the third compartment, stir for 20min, and stir at a speed of 10r / min. The effluent from the flocculation tank enters the rotary drum continuous centrifuge fo...

Embodiment 2

[0026] (1) Heat the drilling wastewater to 40°C for physical demulsification. The reaction time is 10 minutes to precipitate the dissolved impurities in the wastewater.

[0027] (2) Add NaOH to the heated wastewater to adjust the pH of the wastewater to 12. Then the waste water enters the mechanical stirring flocculation tank, and the first column is added polyaluminum chloride (PAC) 50mg / L, the stirring time is 30s, and the stirring speed is 40r / min, so that the coagulant is fully mixed and the impurities in the water are destabilized. The mixing time of two grids is 10min, and the stirring speed is 6r / min, so that the impurities in the wastewater are coagulated and flocculated. Add polyacrylamide (PAM) 5mg / L to the third cell, stirring time 10min, stirring speed 5r / min, the effluent from the flocculation tank enters the rotary drum continuous centrifuge for mud-water separation, and the separated sludge is transported out after drying and separated The liquid enters the air...

Embodiment 3

[0032] (1) Heat the drilling wastewater to 36°C for physical demulsification, and the reaction time is 6 minutes to precipitate the dissolved impurities in the wastewater.

[0033] (2) Add NaOH to the heated wastewater to adjust the pH of the wastewater to 10. Then the waste water enters the mechanical stirring flocculation tank, and the first block is added polyaluminum chloride (PAC) 80mg / L, the stirring time is 45s, and the stirring speed is 50r / min, so that the coagulant is fully mixed and the impurities in the water are destabilized. The stirring time of two grids is 15min, and the stirring speed is 10r / min, so that the impurities in the wastewater are coagulated and flocculated. Add polyacrylamide (PAM) 10mg / L to the third cell, stir for 15 minutes, and stir at a speed of 8r / min. The liquid enters the air flotation device for further processing.

[0034] (3) Add polyaluminum chloride (PAC) 35mg / L to the separation liquid and mix thoroughly, and pass through the air flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com