Method for removing carbon black and high polymer in preparation of acetylene by cracking natural gas with plasma

A plasma and natural gas technology, applied in the direction of adsorption purification/separation, organic chemistry, etc., can solve the problems of large reaction gas resistance, poor removal effect, high device investment, etc., achieve low gas resistance, reduce the number of treatments, and meet process requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

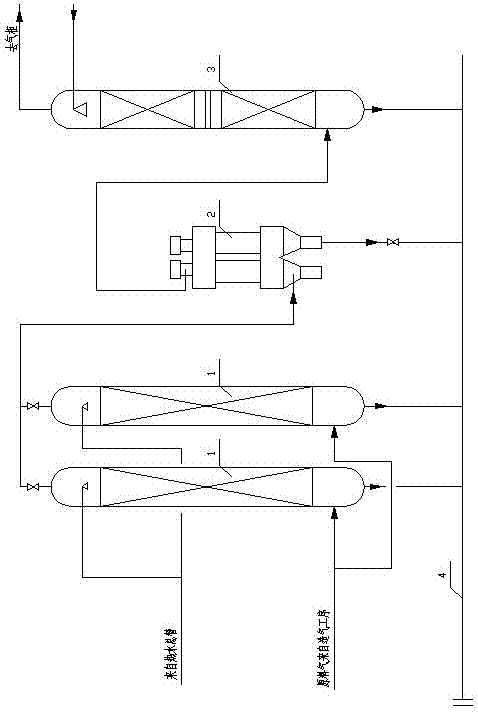

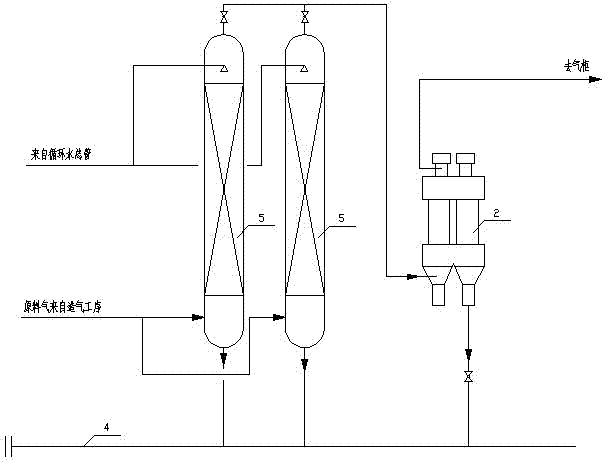

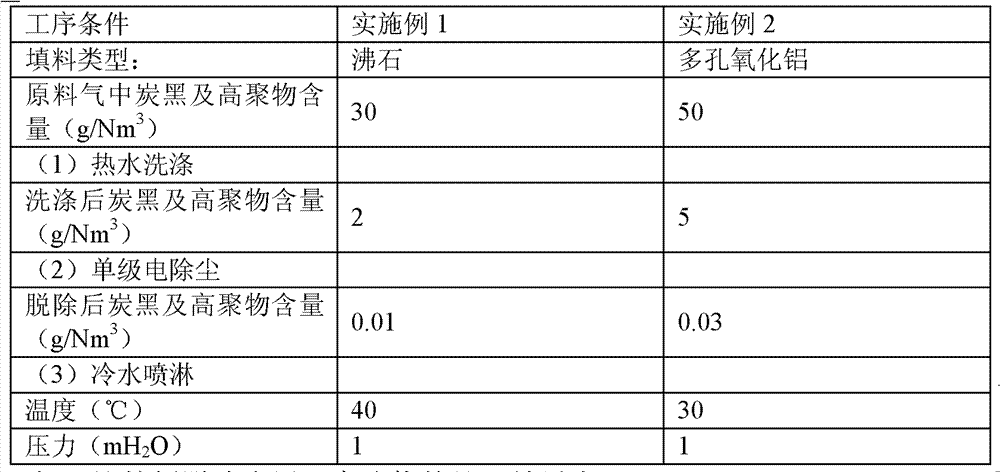

[0022] Embodiment 1: as figure 1 Shown, a kind of method that removes carbon black and high polymer in plasma cracking natural gas to produce acetylene comprises the following steps:

[0023] A, cracked gas from gas-making process (carbon black particle content 30g / Nm 3 ) enters the feed end at the bottom of the hot water scrubber 1, and after being sprayed and washed with hot water and adsorbed by the porous filler, enters the feed end of the electrostatic precipitator 2 from the discharge end at the top of the hot water scrubber 1 through a pipeline;

[0024] B. After being treated by the electrostatic precipitator 2 (the electric precipitator voltage is 50kV), the gas enters the feed end at the bottom of the washing tower 3 through the pipeline, and passes through the cooling water (the temperature is 40°C and the pressure is 1mH) 2 O) After spraying and cooling to about 40°C, it enters the feed end of the gas cabinet.

[0025] The temperature of the hot water for sprayin...

Embodiment 2

[0026] Embodiment 2: as figure 1 Shown, a kind of method that removes carbon black and high polymer in plasma cracking natural gas to produce acetylene comprises the following steps:

[0027] A, cracked gas from gas-making process (carbon black particle content 50g / Nm 3 ) enters the feed end at the bottom of the hot water scrubber 1, and after being sprayed and washed with hot water and adsorbed by the porous filler, enters the feed end of the electrostatic precipitator 2 from the discharge end at the top of the hot water scrubber 1 through a pipeline;

[0028] B. After being treated by the electrostatic precipitator 2 (the electric precipitator voltage is 60kV), the gas enters the feed end at the bottom of the washing tower 3 through the pipeline, and passes through the cooling water (the temperature is 30°C and the pressure is 1mH) 2 O) After spraying and cooling to about 40°C, it enters the feed end of the gas cabinet.

[0029] In the step A, the temperature of the hot wa...

Embodiment 3

[0030] Embodiment 3: as figure 1 Shown, a kind of method that removes carbon black and high polymer in plasma cracking natural gas to produce acetylene comprises the following steps:

[0031] A. Cracked gas from gas-making process (carbon black particle content 30~50g / Nm 3 ) enters the feed end at the bottom of the hot water scrubber 1, and after being sprayed and washed with hot water and adsorbed by the porous filler, enters the feed end of the electrostatic precipitator 2 from the discharge end at the top of the hot water scrubber 1 through a pipeline;

[0032] B. The gas processed by the electrostatic precipitator 2 enters the feed end at the bottom of the washing tower 3 through the pipeline, and is cooled by water (the temperature is 25°C and the pressure is 1mH 2 O) After spraying and cooling to about 35°C, it enters the feed end of the gas cabinet.

[0033] The temperature of the hot water for spray washing in the step A is 90°C. The porous filler is porous alumina ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com