Composite substrate material of conductive spinel structure MgIn2O4/MgO and its prepn

A composite substrate and spinel-type technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of increasing device volume, less use, waste of raw materials, etc., and achieve simple preparation process and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

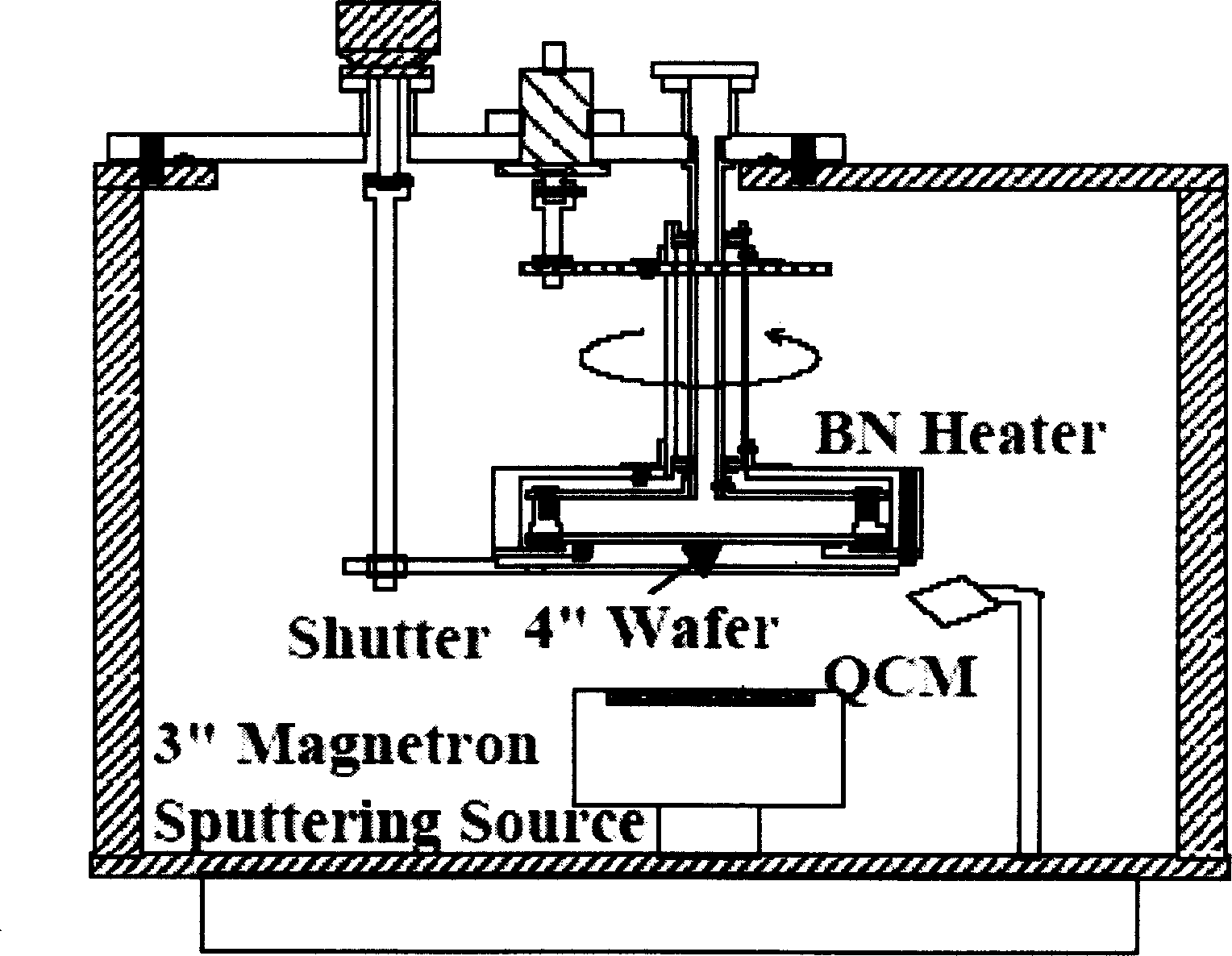

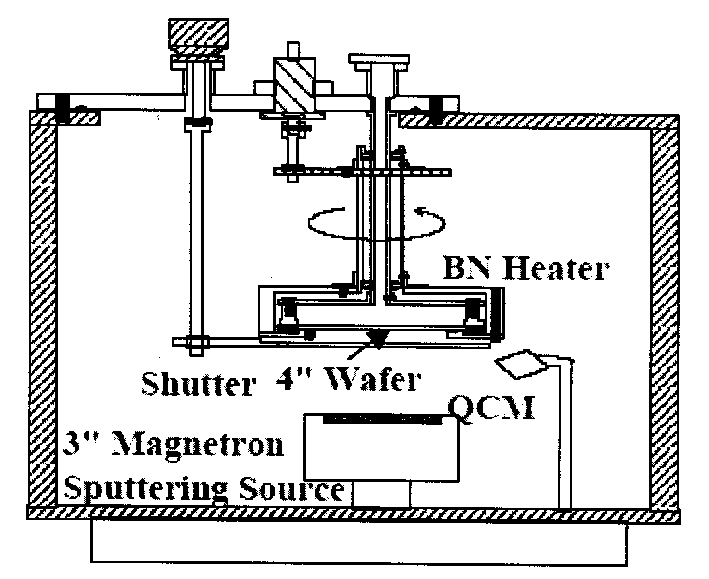

[0030] figure 1 is a schematic diagram of the magnetron sputtering apparatus. The sputtering mechanism is Ar + Accelerated by an electric field, it becomes a high-energy incident particle that hits In 2 o 3 The target material transfers part of the momentum to the target atom, and the target atom collides with other target atoms to form a cascade process. In this cascade process, some target atoms near the surface obtain enough momentum to move outward and leave the target. It is sputtered out, falls on the MgO single crystal substrate placed a few centimeters away from the surface of the target, adheres and accumulates to deposit In 2 o 3 film. In the usual sputtering method, the sputtering efficiency is not high, adding a magnetic field can increase the ionization efficiency of argon (Ar), thereby improving the sputtering efficiency.

[0031] The radio frequency magnetron sputtering technique of the present invention prepares composite substrate material MgIn 2 o 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com