Method for refining stainless steel with high purity

A stainless steel and refining furnace technology, applied in the field of refining high-purity stainless steel, can solve problems such as difficulty in removing sulfur, increased oxygen content, and poor purity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

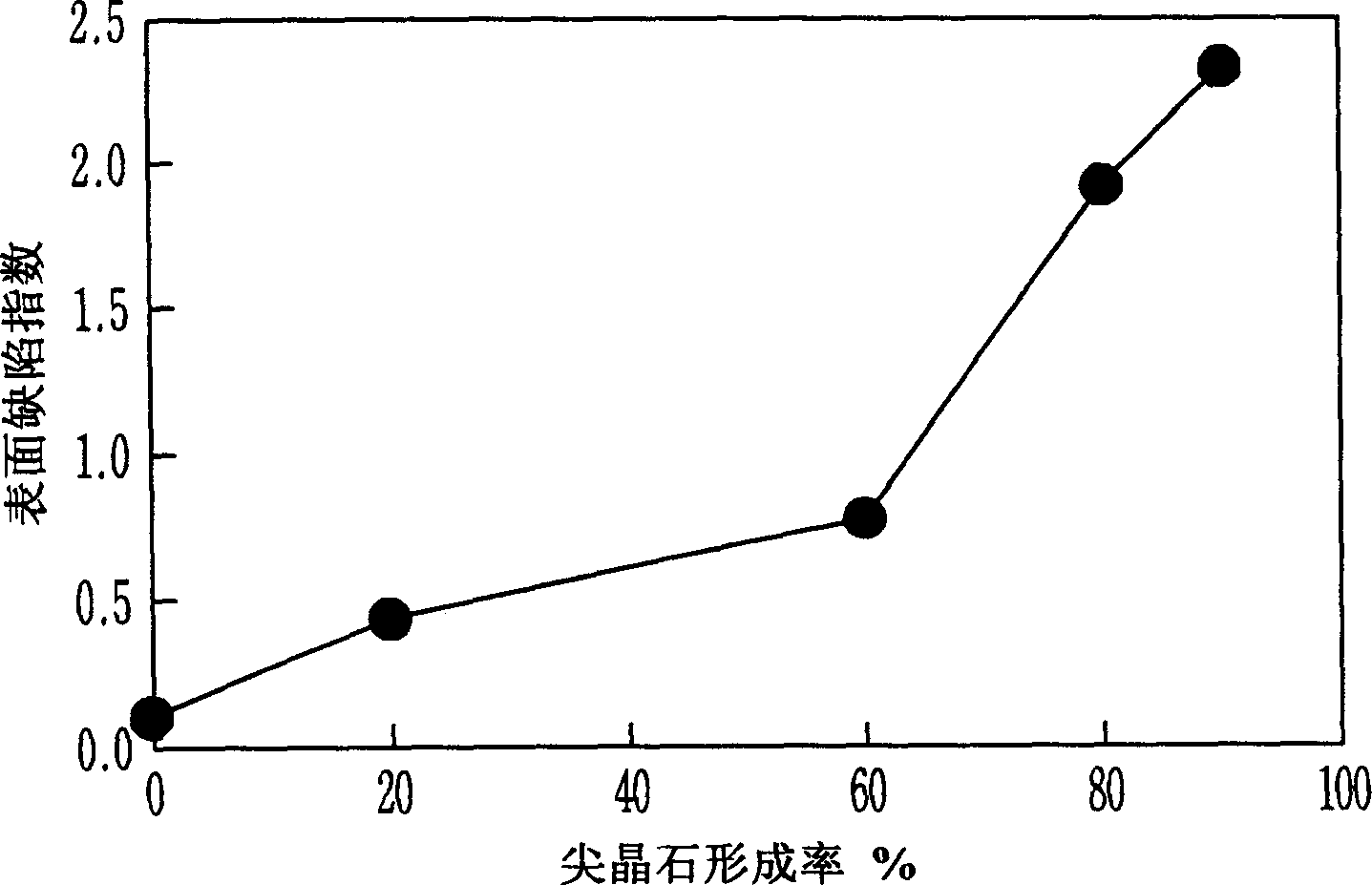

[0036] During the production of STS 430 steel (16.5%Cr) using electric furnace, AOD refining furnace, ladle and continuous casting, the raw material consisting of scrap and ferrochromium (Fe-Cr) is melted in a 90-ton electric furnace and subsequently used in AOD Oxygen-argon mixed gas for decarburization and refining. After decarburization and refining, in order to reduce and recover oxidized chromium, add Si, quicklime and fluorite and blow argon for reduction refining. Then tap the steel. In the ladle, argon is blown in while adjusting the final composition and temperature for stirring. Thereafter, by continuous casting, a slab having a width of 1200 mm and a thickness of 200 mm was cast. The cast slab was hot-rolled and cold-rolled, and as a result, a 0.6 mm thick cold-rolled steel sheet was obtained.

[0037] Table 1 below shows the composition of the STS 430 steel used in the present invention. When inspecting inclusions, take a sample at the center of the slab, use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com