Case material for microwave oven

A shell material and technology for microwave ovens, which are applied in the field of observation windows, can solve the problems of reducing the microwave protection capability of the shell, and the user cannot clearly observe the food condition, and achieve the effect of good transmission characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

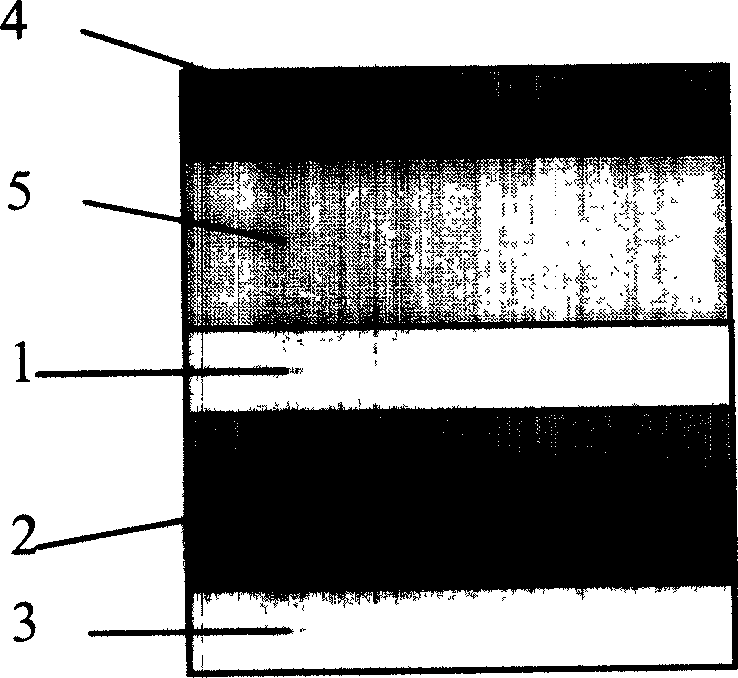

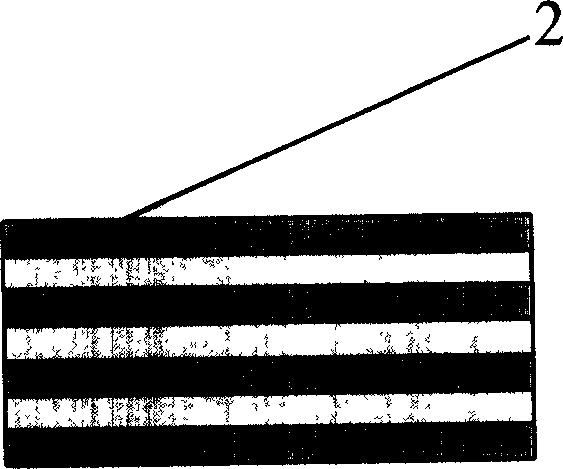

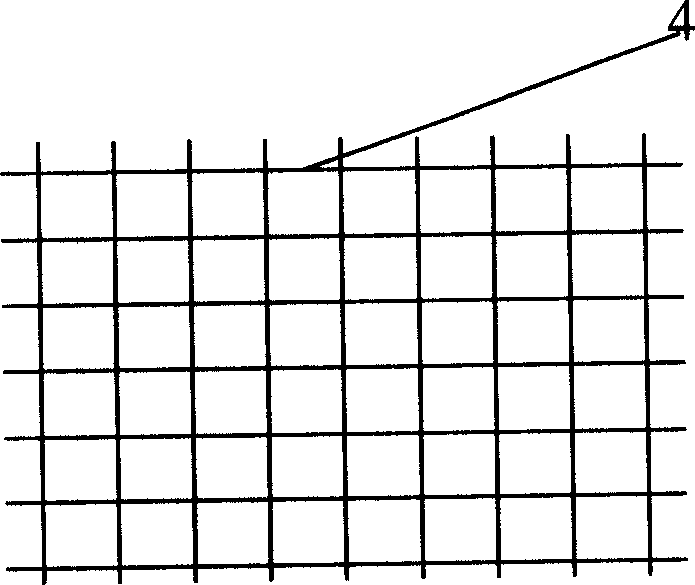

[0012] Such as figure 1 As shown, a microwave oven casing material of the present invention includes a wire mesh, the wire mesh is single or multiple, the wire mesh is connected with a metal-dielectric composite film, and the metal-dielectric composite film The thin film includes a single-layer or multi-layer semiconductor quantum well-like symmetrical structure. Among them, the wire mesh such as figure 1 As shown in 4, it consists of two sets of mutually perpendicular copper wires, the diameter of the copper wires is 0.045 mm, and the distance between any two adjacent parallel copper wires in each set of copper wires is 5 mm. There is no direct conduction between the two sets of copper wires, and they are all fused in the quartz glass. One side of the glass is compounded with a single-layer or multi-layer metal-dielectric multilayer film with a semiconductor quantum well structure, and in this design there is a structure with a 1 / 4 wavelength optical path as described above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com