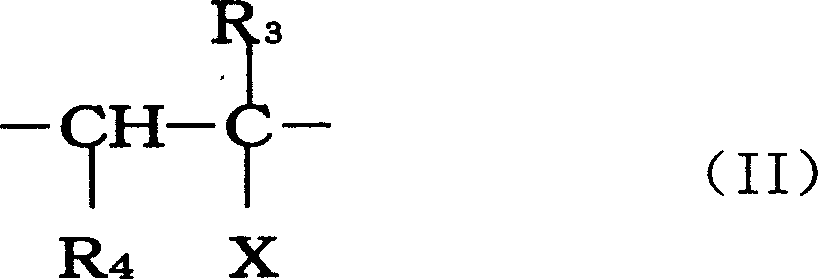

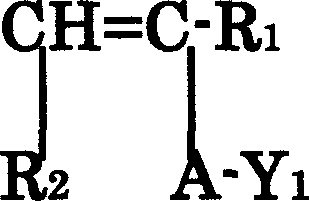

Method for synthetizing anion type and non-ion type dispersoid for water-soluble polymer

A non-ionic polymer and non-ionic technology, used in the synthesis of anionic and/or non-ionic water-soluble polymer dispersions, can solve the problem of high-viscosity products that have not been reported in the addition of polymers and polyols Separation stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]In a 500 ml 4-neck round bottom flask equipped with a condenser, thermometer, nitrogen inlet and stirrer, add 77.4 grams of deionized water, 136.6 grams of ammonium sulfate, 17.6 grams of 60% acrylic acid, 189.1 grams of 50% Acrylamide, 2.9 grams of 30% sodium hydroxide to neutralize the anionic monomer of 15 mol%, the copolymer of acrylamide and N,N-dimethylacryloyl of 18.6 grams (3% of the monomer amount) ( Molecular weight is 150,000, concentration 20%), 3.5 gram glycerin (3.2% of monomer weight), be warming up to 25 degree under the condition of stirring, after logical nitrogen 30 minutes, add 0.1 of 2.6 gram ammonium peroxosulfate and sodium sulfite respectively % aqueous solution. After 2.5 hours of reaction, the viscosity of the system can be observed, but with the precipitation of particles, the viscosity of the system no longer increases. After continuing to react for 12 hours, a polymer dispersion was obtained. Particles with a particle diameter of 5-10 micron...

Embodiment 2-4

[0033] The reaction device and operation method were the same as those in Example 1. By changing the molar ratio of acrylic acid monomers to acrylamide monomers as shown in Table 2, a polymer dispersion was synthesized. The results are shown in Table 3.

Embodiment 5

[0035] The reaction apparatus is as in Example 1, adding 57.9 grams of deionized water, 135.4 grams of ammonium sulfate, 14.9 grams of 2-acrylamido-2-methylpropanesulfonic acid, 10.4 grams of 60% concentration of acrylic acid, 173.8 grams of 50% concentration of propylene Amide, 3.8 grams of 30% concentration of sodium hydroxide to neutralize the anionic monomer of 13 mol %, 16.9 grams (3% of the monomer amount) poly N-vinylpyrrolidone (molecular weight is 10,000, concentration 20%), 3.3 Vinyl alcohol (3.0% of the monomer weight) was heated up to 25° C. with stirring, and after 30 minutes of blowing nitrogen, 2.6 g of ammonium peroxosulfate and 0.1% aqueous solution of sodium sulfite were added respectively. After 2.5 hours of reaction, the viscosity of the system can be observed, but with the precipitation of particles, the viscosity of the system no longer increases. After continuing to react for 15 hours, the polymer dispersion was obtained, and particles with a particle di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com