Method for making soft magnet silicon aluminium alloy powder core

An iron-silicon-aluminum alloy and silicon-aluminum alloy technology, which is applied in the field of manufacturing soft magnetic inductor cores, can solve the problems of AC and DC superposition drop performance and low magnetic permeability that do not involve powder cores, and achieves low cost and easy production. , strong safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put industrial pure iron, crystalline silicon, and pure aluminum into a high-frequency induction furnace with a nominal value of 50 kg for smelting, and cast it into an alloy ingot with a chemical composition of 84.80% iron, 9.53% silicon, and 5.62% aluminum, and mechanically cast the alloy ingot Coarsely crushed into chunks below 25mm, put these chunks into a general reduction furnace with a hydrogen protective atmosphere and keep them warm for about 2 hours at a temperature of about 1200°C, then cool them down, and then use a jaw crusher to further crush them The material block is broken into a material block smaller than 6 mm, and then crushed into an alloy powder below 100 mesh by a vibrating ball mill. The alloy powder is placed in a general reduction furnace with a hydrogen protective atmosphere and kept at a temperature of about 900 ° C for 1 hour. Stress annealing treatment, after sieving, according to the mass ratio of 100-200 mesh accounting for 20%, 200-325 me...

Embodiment 2

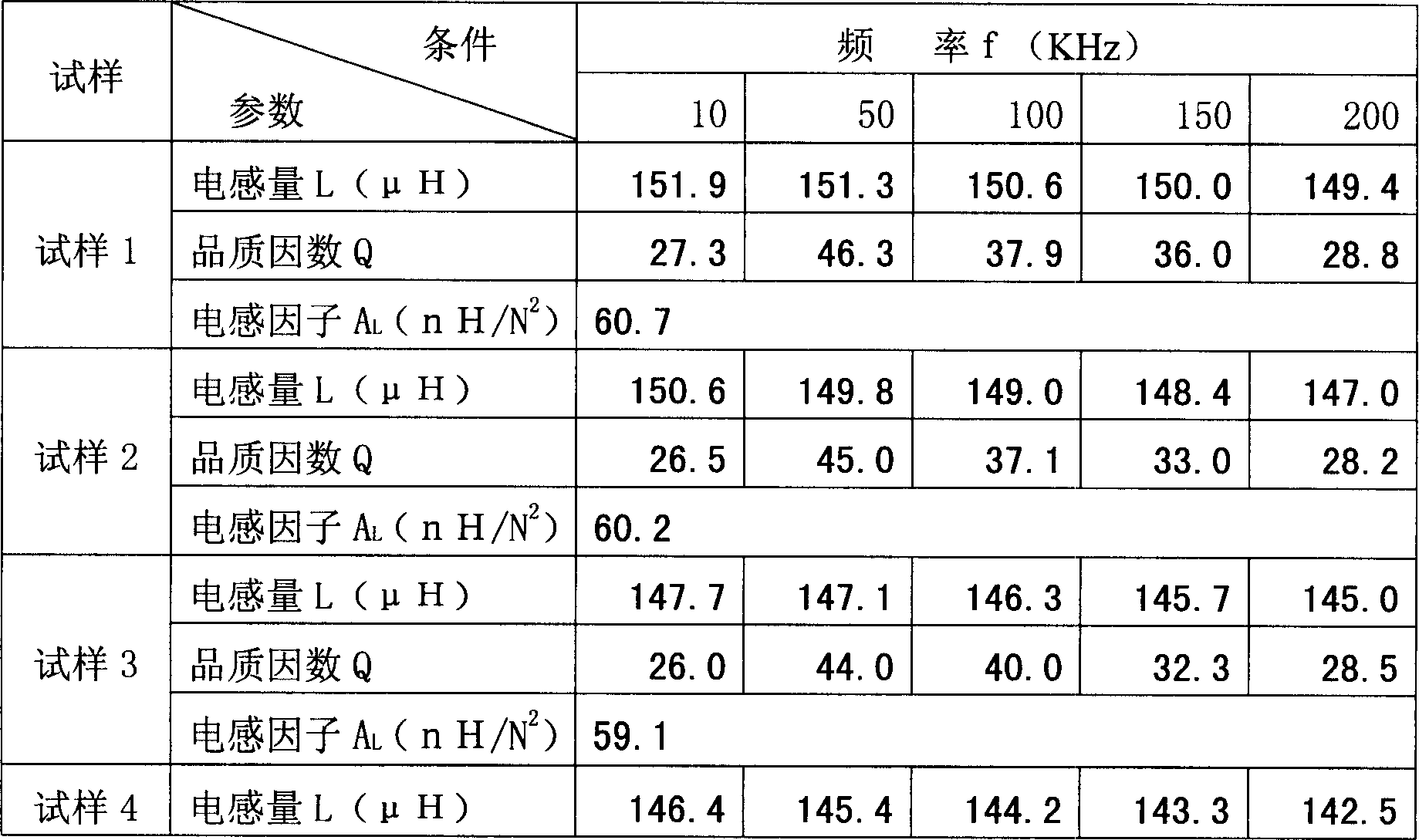

[0027] According to the processing step of embodiment one, the glue solution (that is, W-6A or W-6C magnetic powder adhesive equivalent to 2.0% of the alloy powder quality) that is equivalent to 6.0% of the alloy powder quality is poured into the alloy powder, and all the other conditions No change, get a soft magnetic powder core with the specifications of Φ12.80 / Φ7.20×5.0. Its magnetic performance parameters are shown in Table 4 and Table 5:

[0028] Table 4

[0029]

[0030] Quality factor Q

28.0

40.3

31.3

26.2

21.9

Inductance factor A L (nH / N 2 )

60.1

[0031] The data in Table 4 shows that the inductance factors of samples 5, 6, 7, and 8 are basically in A L =56×(1±8%)nH / N 2 In the range of , the corresponding effective permeability (μ e ) is about 125, which is higher than the performance of the soft magnetic powder core manufactured by the existing method.

[0032] Table 5 (DC superposition res...

Embodiment 3

[0036] According to the processing step of embodiment one, the glue solution (that is, W-6A or W-6C magnetic powder adhesive equivalent to 3.0% of the alloy powder quality) that is equivalent to 9.0% of the alloy powder quality is poured into the alloy powder, and all the other conditions No change, get a soft magnetic powder core with the specifications of Φ12.80 / Φ7.20×5.0. Its magnetic performance parameters are shown in Table 6 and Table 7:

[0037] Table 6

[0038]

[0039] Quality factor Q

25.7

48.5

40.4

35.0

28.0

Inductance factor A L (nH / N 2 )

53.9

[0040] The data in Table 6 shows that the inductance factors of samples 9, 10, 11, and 12 are basically in A L =56×(1±8%)nH / N 2 In the range of , the corresponding effective permeability (μ e ) is about 125, which is higher than the performance of the soft magnetic powder core manufactured by the existing method.

[0041] Table 7 (DC superposition re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com