Chromium oxide coating preparing process

A preparation process and chromium oxide technology, which is applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of easy deformation and cracking of the target surface, the operating power cannot be too high, and the substrate is difficult to deposit locally. The effect of fast film formation, low cost, and fast deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

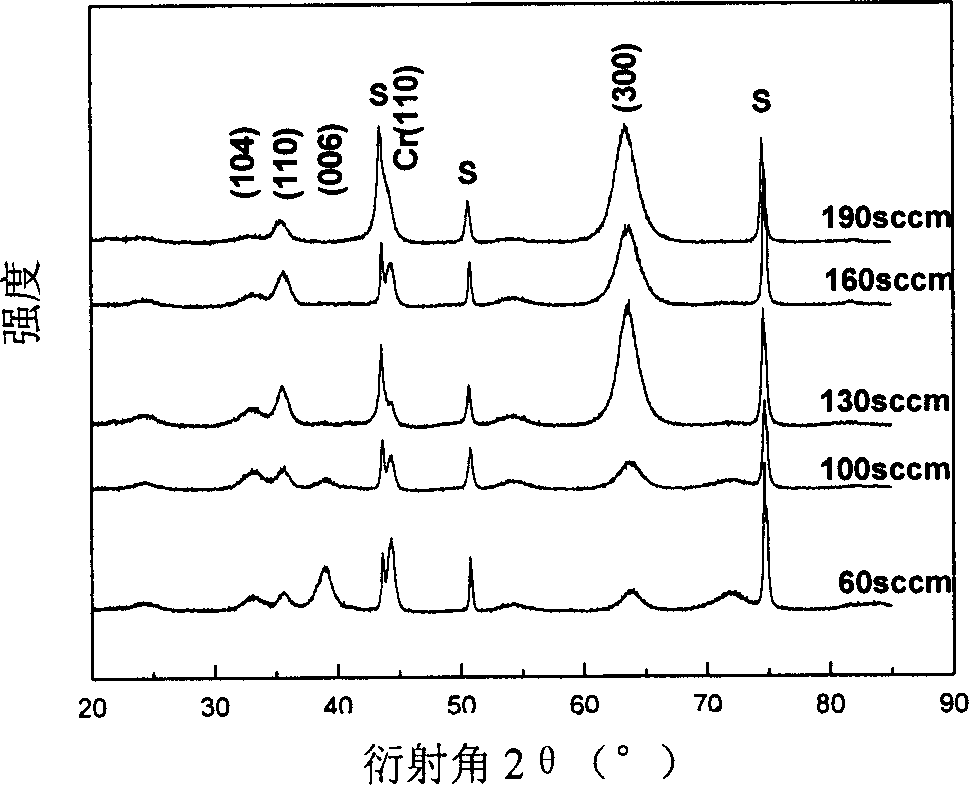

Embodiment 1

[0028] The equipment used is the MIP-8-800 ion coating machine, using pure chromium as the cathode target, the anode is connected to the vacuum chamber, the cathode and the anode are respectively connected to the negative pole and positive pole of the low-voltage, high-current DC power supply, the current is 50A, and the voltage is 20V; the size of the substrate is: 15mm×10mm×2mm, the material is 18-8 stainless steel, the substrate is ground and polished by metallographic sandpaper, cleaned with ultrasonic waves in acetone for 15min, dried, and placed on the sample stage in the vacuum deposition chamber. The distance between the substrate and the target is about 240mm, and the vacuum degree reaches 8×10 -3 Pa, first pass into the Ar gas, the pressure is 7×10 -2 Pa, add a high bias voltage of -1000V before coating. a : 50A, arc voltage: 20V, after the substrate is bombarded, oxygen is introduced, only the oxygen flow rate is changed: 60~190sccm, working pressure: 6.0×10 -1 Pa...

Embodiment 2

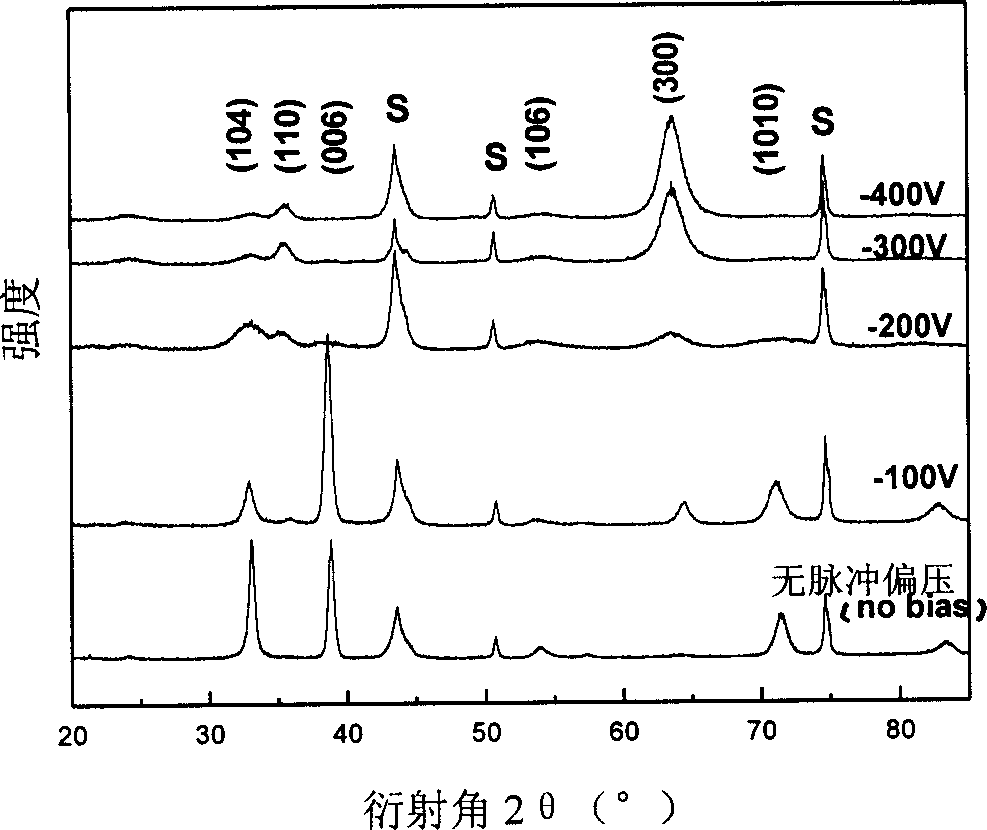

[0032] The difference from Example 1 is:

[0033] The current of the DC power supply is 100A, and the voltage is 40V; the size of the substrate is: 15mm×10mm×2mm, and the material is 18-8 stainless steel. On the sample stage in the vacuum deposition chamber, the distance between the substrate and the target is about 150 mm. After the furnace is installed, the vacuum chamber is evacuated to a vacuum degree of 6.0×10 -3 Pa, through Ar gas, the pressure is 5×10 -2 Pa, add a high bias voltage of -700V before coating, and the high bias voltage is a pulse bias voltage; utilize glow discharge to bombard the surface of the substrate for 5min, arc current I a : 50A, arc voltage: 20V; after the bombardment of the substrate, oxygen is introduced, the oxygen flow rate: 130sccm, the working pressure: 4.0×10 -1 Pa, only changing the pulse bias voltage: 0 ~ -400V, the duty ratio is 20%, and the deposition time is 30min.

[0034] Such as figure 2 As shown, S represents the matrix, and th...

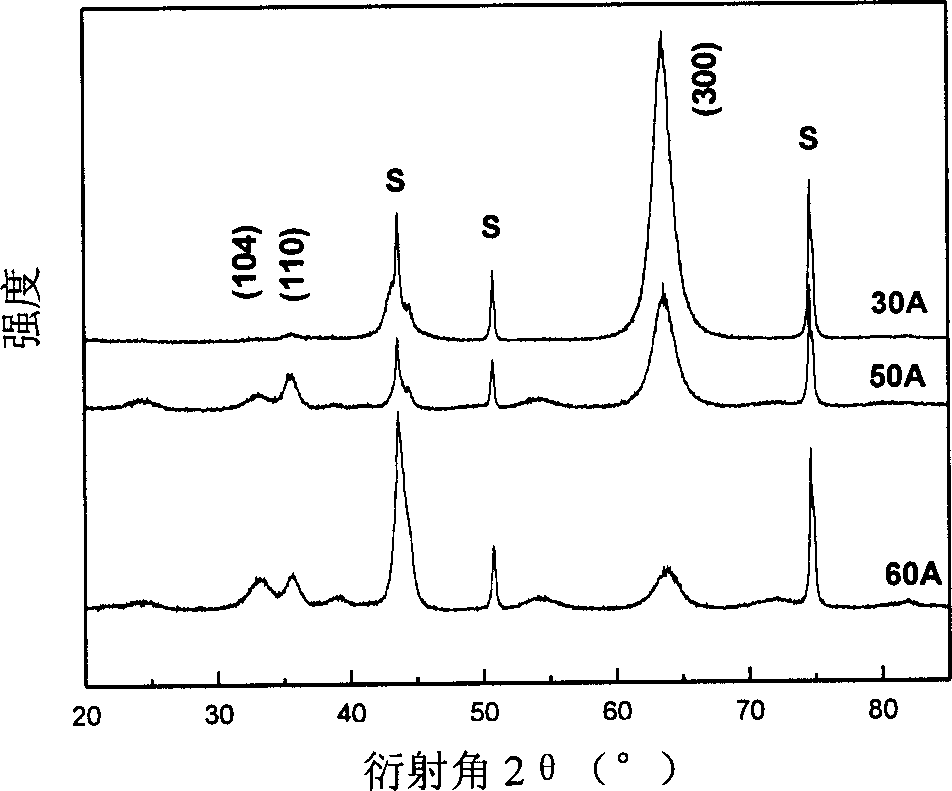

Embodiment 3

[0036] The difference from Example 1 is:

[0037] The current of the DC power supply is 75A, and the voltage is 30V; the size of the substrate is: 15mm×10mm×2mm, and the material is 18-8 stainless steel. On the sample stage in the vacuum deposition chamber, the distance between the substrate and the target is about 280mm. After the furnace is installed, the vacuum chamber is evacuated to a vacuum degree of 6.0×10 -3 Pa, the substrate is heated to 150°C and Ar gas is introduced, the pressure is 6×10 -2 Pa, add a high bias voltage of -800V before coating, the high bias voltage is a pulse bias voltage; use glow discharge to bombard the surface of the substrate for 3min, only change the arc current I a : 30 ~ 60A, arc voltage: 20 ~ 40V; after the bombardment of the substrate, oxygen is introduced, oxygen flow rate: 130sccm, working pressure: 8.0×10 -1 Pa, the pulse bias voltage is -300V, the duty cycle is 20%, and the deposition time is 30min.

[0038] Such as image 3 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com