Super-thin copper foil with carrier, its mfg. method and printed wiring base plate

A technology of ultra-thin copper foil and manufacturing method, which is applied in the manufacture of printed circuit precursors, printed circuits, printed circuit manufacturing, etc., and can solve the problems of copper foil fracture, easy wrinkles and creases, and low mechanical strength of thin copper foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

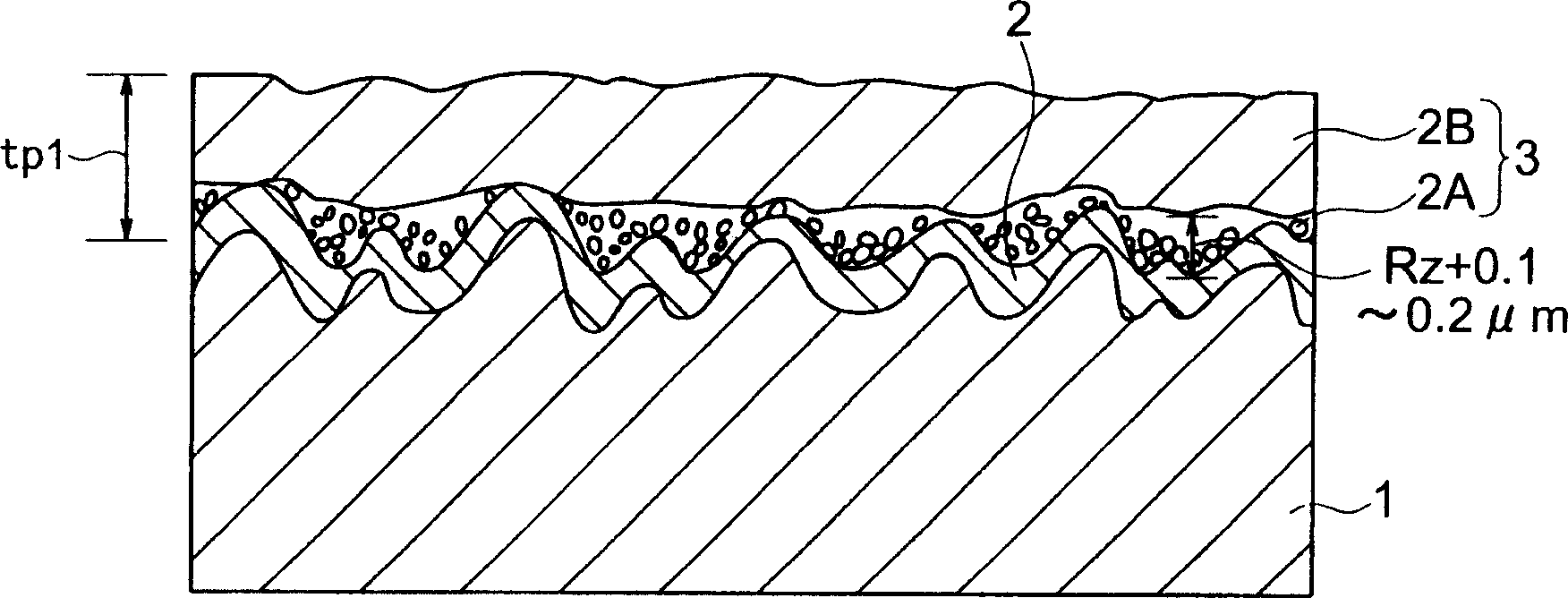

[0063] Example 1 ( figure 1 )

[0064] 1. Preparation of carrier copper foil: As carrier copper foil 1, an untreated electrolytic copper foil with a thickness of 31 μm and a gloss surface roughness Rz=1.5 μm was prepared.

[0065] 2. Forming a peeling layer: Continuously conduct electrical treatment on the glossy surface of the carrier copper foil 1 to form a metal Cr adhesion amount of 0.50mg / dm 2 Metallic chrome peel off layer 2.

[0066] 3. Form a strike plating layer containing P on the surface of the peeling layer 2 and its vicinity: then on the peeling layer 2,

[0067] Cu 2 P 2 o 7 ·3H 2 O: 30g / L

[0068] K 4 P 2 o 7 : 300g / L

[0069] pH: 8

[0070] Current density in solution: 1.5A / dm 2 Strike plating was performed for 30 seconds under the conditions of , and a P-containing layer 2A was formed on the surface of the release layer and its vicinity.

[0071] 4. Form extremely thin copper foil: then on the strike plating layer 2A containing P, on...

Embodiment 2

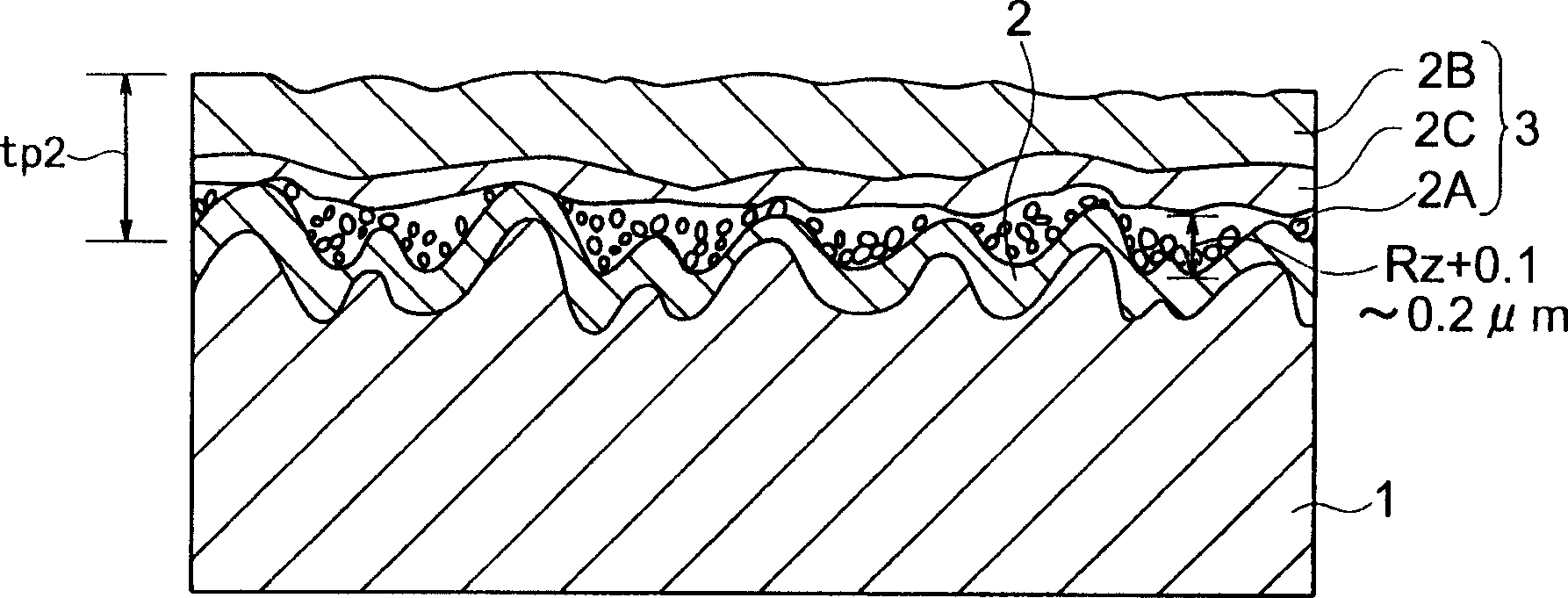

[0077] Example 2 ( figure 2 )

[0078] 1. Preparation of carrier copper foil: As carrier copper foil 1, an untreated electrolytic copper foil with a thickness of 31 μm and a gloss surface roughness Rz=0.2 μm was prepared.

[0079] 2. Forming a peeling layer: Continuously conduct electrical treatment on the glossy surface of the carrier copper foil 1 to form a layer with a Cr adhesion of 0.30 mg / dm 2 The release layer 2 is composed of a hydrated oxide film.

[0080] 3. Form a strike plating layer containing P on the surface of the peeling layer 2 and its vicinity: then on the peeling layer 2,

[0081] Cu 2 P 2 o 7 ·3H 2 O: 30g / L

[0082] K 4 P 2 o 7 : 300g / L

[0083] Current density: 1.5A / dm in solution of pH: 8 2 Strike plating was performed for 60 seconds under the same conditions to form a P-containing layer 2A on the surface of the release layer 2 and its vicinity.

[0084] 4. Forming ultra-thin copper foil-1: Then use it on the strike plating ...

Embodiment 3

[0094] Embodiment 3 ( figure 2 )

[0095] 1. Preparation of carrier copper foil: As carrier copper foil 1, an untreated electrolytic copper foil with a thickness of 35 μm and a gloss surface roughness Rz=0.8 μm was prepared.

[0096] 2. Forming a peeling layer: Continuously conduct electrical treatment on the glossy surface of the carrier copper foil 1 to form a layer with a metal adhesion of 0.50 mg / dm 2 The release layer 2 is composed of metal chromium and hydrated oxide film.

[0097] 3. Form a layer containing P on the surface of the peeling layer 2 and its vicinity: then on the peeling layer,

[0098] Cu 2 P 2 o 7 ·3H 2 O : 16g / L

[0099] K 4 P 2 o 7 : 300g / L

[0100] Current density: 1.5A / dm in solution of pH: 8 2 Strike plating was performed for 60 seconds under the same conditions to form a P-containing layer 2A on the surface of the release layer 2 and its vicinity.

[0101] 4. Forming an extremely thin copper layer-1: Then use it on the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com