Tubular wire rod for double-electrode gas protective welding, its welding method and appts.

A technology of gas shielding and welding methods, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of not being able to use only one electrode, complex, large, etc., and achieve the effect of good welding operability and good low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

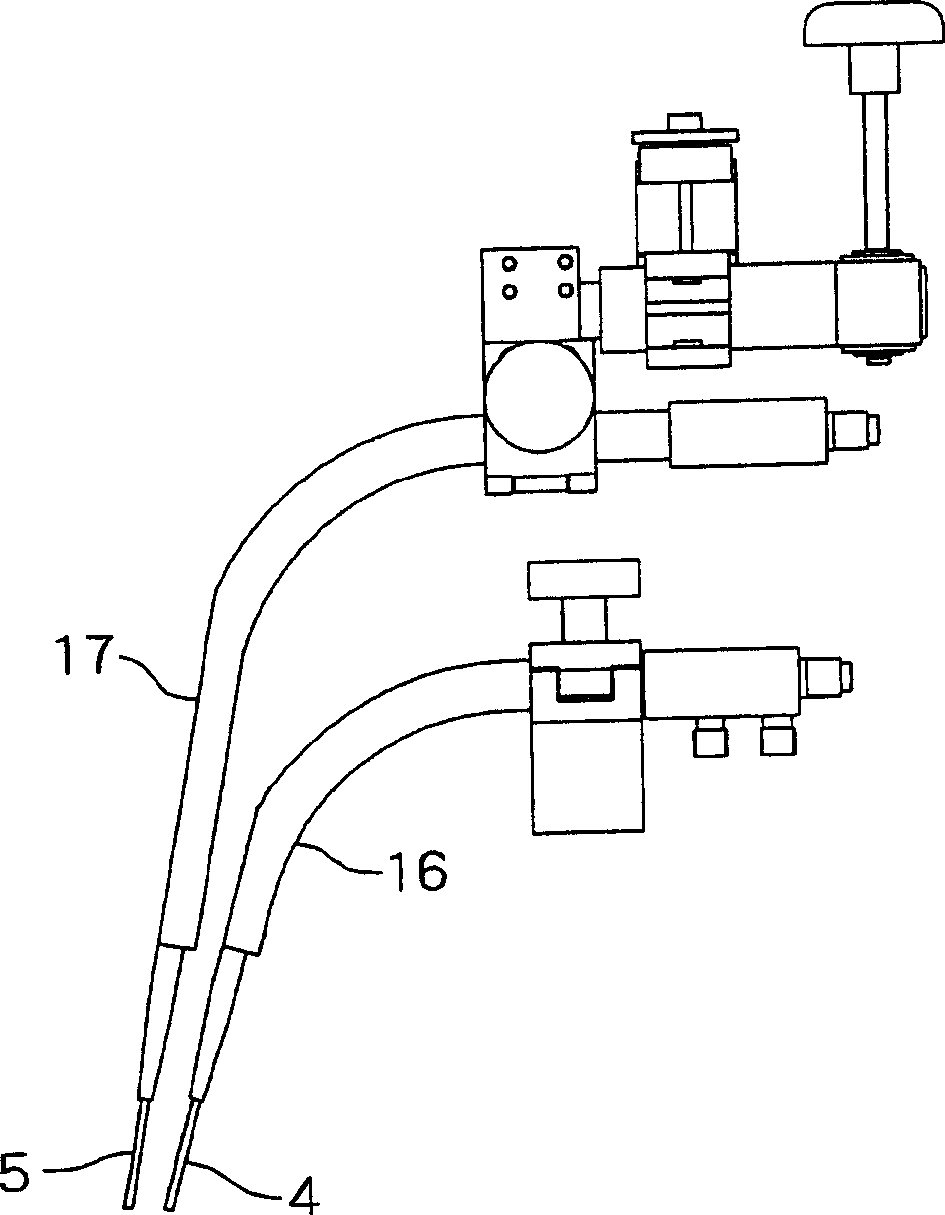

Image

Examples

Embodiment 1

[0065] Hereinafter, examples of the present invention will be described in comparison with comparative examples outside the scope of the present invention. Table 4 below shows the types, polarities, and vibration conditions of welding wires used in Examples and Comparative Examples. In addition, the following Table 5 shows the welding workability of each Example and a comparative example. Among them, FCW in Table 4 is a tubular welding wire (Flux Cored Wire), ○ in Table 5 means that it has the same performance as Examples 1-8, ◎ means it is better than Examples 1-8, and △ means it is better than Examples 1-8. Slightly worse, × means poor. In addition, for the test conditions, the shape of the welded plate 1 is 80mm thick, 500mm wide, and 3000mm long, the groove angle is 20°, the groove shape is V-shaped, the groove gap is 4mm on the welding start side, and the welding end is one The side is 8mm. That is, considering the variation of the actual weldment gap, a tapered weld w...

Embodiment 2

[0077] Next, Example 2 of the present invention will be described. In Example 2, first, tubular welding wires having the compositions shown in Table 7 below were produced. Furthermore, in the welding wire composition shown in Table 4, the remainder is Fe, Si, C, etc. In Comparative Example No. 3-21, a conventional tubular welding wire was used.

[0078] 【Table 7】

[0079] Next, using the various welding wires of Examples and Comparative Examples, a double-electrode gas shielded welding method is used to perform vertical welding single pass welding on a plate to be welded with a thickness of 80mm, a width of 500mm, and a length of 1500mm, and evaluate the welding operability and weld metal impact performance. The welding conditions at this time were that the groove shape was V-shaped, the groove weld bead was 8 mm, and the total heat input was about 600 KJ / cm. In addition, the impact test was performed in accordance with the impact test method for welded joints specified in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com