Infrared upward rotating marking material and its prepn. method

An infrared up-conversion and marking technology, which is applied in the field of infrared up-conversion marking materials, can solve the problems of high cost and unsuitability for large-scale production, and achieve the effects of stable wavelength, lower temperature requirements, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one: synthesize a kind of material by following composition, and the percentage that each composition accounts for raw material gross weight is: Al 2 o 3 5.38%, SiO 2 11.87%, PbF 2 37.16%, CdF 2 19.79%, BaF 2 11.54%, Yb 2 o 3 7.79%, Er 2 o 3 1.26%.

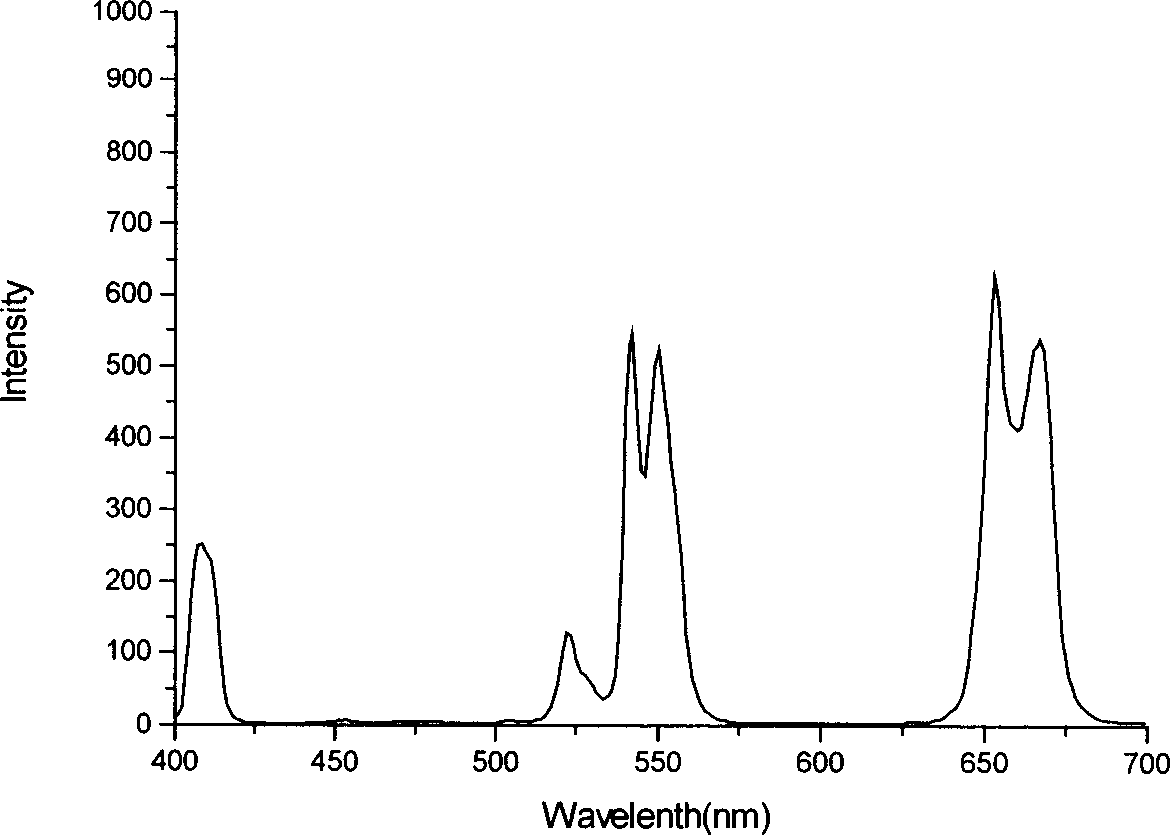

[0034]Weigh 9.34 grams of alumina, 20.68 grams of silicon dioxide, 64.77 grams of lead fluoride, 34.48 grams of cadmium fluoride, 20.11 grams of barium fluoride, 13 grams of ytterbium oxide, and 2.19 grams of erbium fluoride according to the above ratio, and grind them in a ball mill Put it into a platinum crucible for 2 hours, keep the temperature at 350°C for one hour, raise the temperature to 900°C at a rate of 5°C / min, keep it for 120 minutes, cool it down to 450°C at a rate of 5°C / min and keep it for 12 hours, then cool naturally to Take it out at room temperature, and grind it to 300-400 mesh in a ball mill. The infrared up-conversion marking material emits red and green bicolor light under...

Embodiment 2

[0036] Embodiment two: synthesize a kind of material by following composition, and the percentage that each composition accounts for raw material gross weight is: Al 2 o 3 5.91%, SiO 2 13.04%, PbF 2 40.82%, CdF 2 27.17%, YbF 3 11.66%, Er 2 o 3 1.38%.

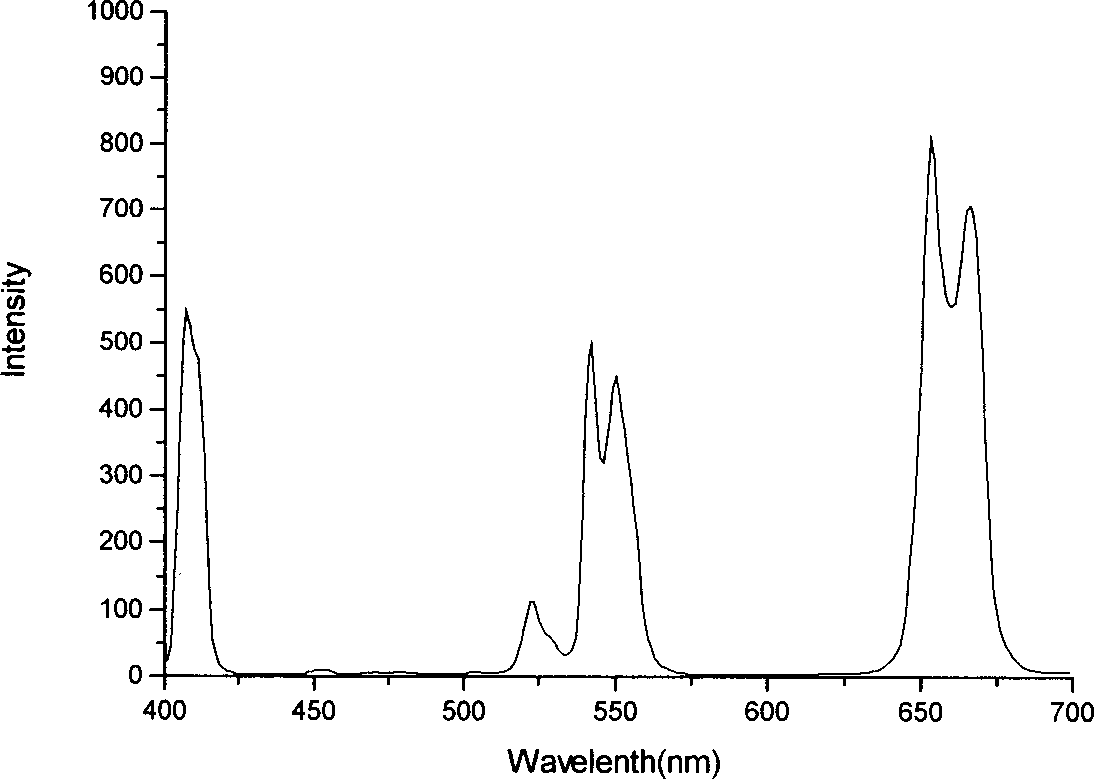

[0037] Weigh 7.21 grams of alumina, 15.91 grams of silicon dioxide, 64.77 grams of lead fluoride, 33.15 grams of cadmium fluoride, 14.2 grams of ytterbium fluoride, and 1.69 grams of erbium fluoride according to the above proportions, grind them in a ball mill for 2 hours, put Put it in a platinum crucible, keep the temperature at 350°C for one hour, raise the temperature to 850°C at a rate of 5°C / min, keep it for 120 minutes, cool it down to 450°C at a rate of 5°C / min and keep it for 12 hours, cool naturally to room temperature, take it out, and Grind in a ball mill to 300-400 mesh. The infrared up-conversion marking material emits red and green bicolor light under the excitation of 980nm infrared light. Among th...

Embodiment 3

[0039] Embodiment three: synthesize a kind of material by following composition, and the percentage that each composition accounts for raw material gross weight is: Al 2 o 3 2.36%, SiO 2 12.96%, PbF 2 43.50%, CdF 2 23.16%, AlF 3 6.48%, Yb 2 o 3 9.12%, Er 2 o 3 1.47%.

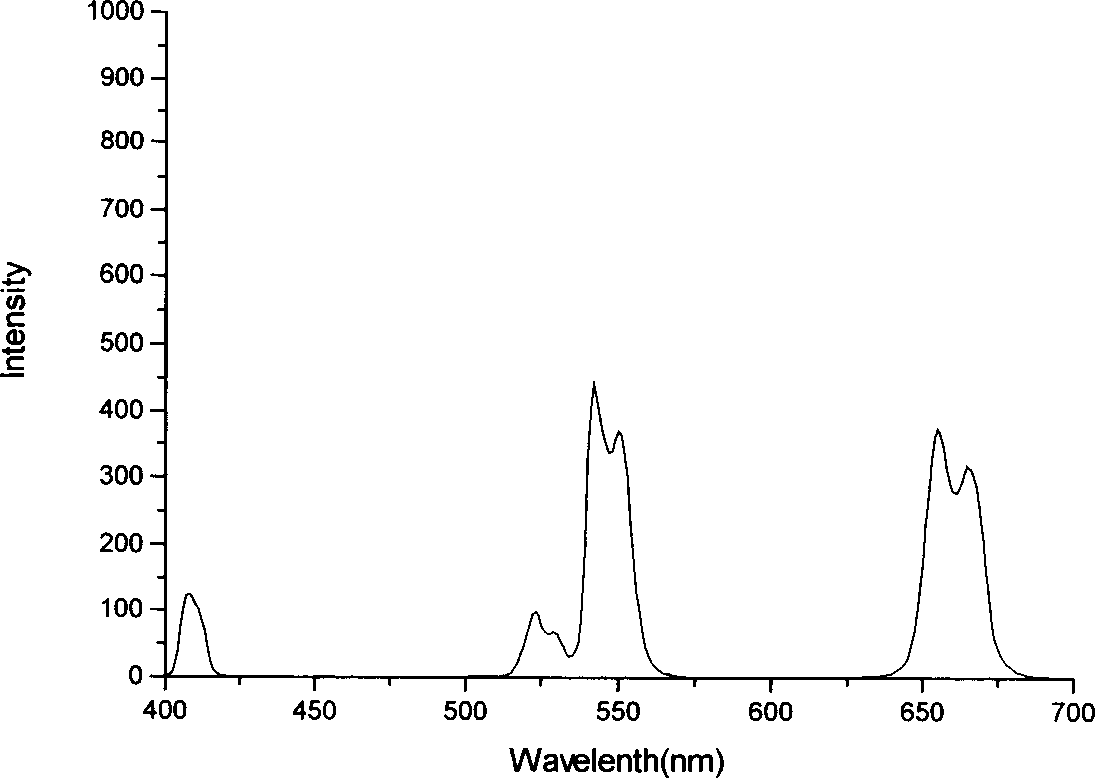

[0040] Weigh 2.93 grams of alumina, 16.09 grams of silicon dioxide, 53.97 grams of lead fluoride, 28.73 grams of cadmium fluoride, 8.04 grams of aluminum fluoride, 9.12 grams of ytterbium oxide, and 1.47 grams of erbium fluoride according to the above ratio, and grind them in a ball mill Put it into a platinum crucible for 2 hours, keep the temperature at 350°C for one hour, raise the temperature to 800°C at a rate of 5°C / min, keep it for 120 minutes, cool it down to 450°C at a rate of 5°C / min and keep it for 12 hours, then cool naturally to Take it out at room temperature, and grind it to 300-400 mesh in a ball mill. The infrared up-conversion marking material emits red and green bicolor light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com