Catalysts for polyester production, process for producing polyester, and polyester

A technology of catalyst and polyester, which is applied in the field of polyester, specifically in the field of polyester, can solve the problems of poor activity, yellow color of product polyester, and unrealized practical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

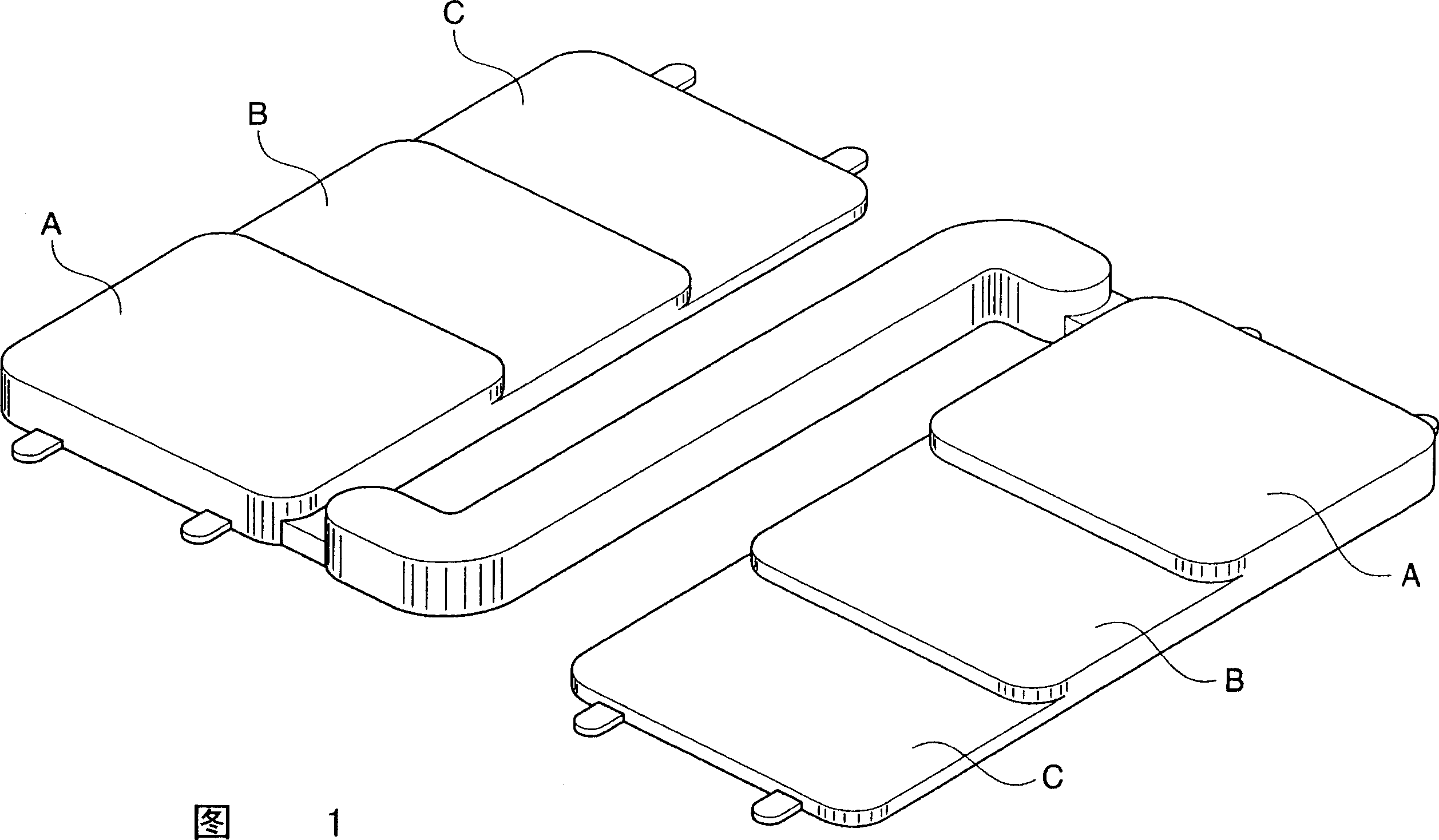

Image

Examples

Embodiment 1

[0218] Preparation of Solid Titanium Compounds

[0219] 500 ml of deionized water was weighed into a 1,000 ml glass beaker and cooled in an ice bath, then 5 g of titanium tetrachloride was added dropwise while stirring. When the generation of hydrogen chloride stopped, the beaker was taken out from the ice bath, and 25% ammonia water was added dropwise while stirring at room temperature to adjust the pH value of the liquid to 9. A 15% aqueous acetic acid solution was added dropwise to the liquid with stirring at room temperature to adjust the pH of the liquid to 5. The precipitate formed was isolated by filtration. The precipitate was washed 5 times with deionized water. After washing, the precipitate was immersed in 10% by weight of ethylene glycol-containing water for 30 minutes, and then solid-liquid separation was performed by filtration similar to washing. After washing, the resulting titanium compound was vacuum-dried at 40° C. and 1.3 kPa (10 Torr) for 20 hours to ...

Embodiment 2

[0223] Preparation of Solid Titanium Compounds

[0224] 500 ml of deionized water was weighed into a 1,000 ml glass beaker and cooled in an ice bath, then 5 g of titanium tetrachloride was added dropwise while stirring. When the generation of hydrogen chloride stopped, the beaker was taken out from the ice bath, and 25% ammonia water was added dropwise while stirring at room temperature to adjust the pH value of the liquid to 9. A 15% aqueous acetic acid solution was added dropwise to the liquid with stirring at room temperature to adjust the pH of the liquid to 5. The precipitate formed was isolated by filtration. The precipitate was washed 5 times with deionized water. After washing, the precipitate was immersed in 30% by weight of ethylene glycol-containing water for 30 minutes, and then solid-liquid separation was performed by filtration similar to washing. After washing, the resulting titanium compound was vacuum-dried at 40° C. and 1.3 kPa (10 Torr) for 40 hours to ...

Embodiment 3

[0228] Preparation of Solid Titanium Compounds

[0229] 500 ml of deionized water was weighed into a 1,000 ml glass beaker and cooled in an ice bath, then 5 g of titanium tetrachloride was added dropwise while stirring. When the generation of hydrogen chloride stopped, the beaker was taken out from the ice bath, and 25% ammonia water was added dropwise while stirring at room temperature to adjust the pH value of the liquid to 9. A 15% aqueous acetic acid solution was added dropwise to the liquid with stirring at room temperature to adjust the pH of the liquid to 5. The precipitate formed was isolated by filtration. The precipitate was washed 5 times with deionized water. After washing, the precipitate was immersed in 50% by weight of water containing ethylene glycol for 30 minutes, and then solid-liquid separation was performed by filtration similar to washing. After washing, the resulting titanium compound was vacuum-dried at 40° C. and 1.3 kPa (10 Torr) for 150 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com