Organic electric luminescent device emitting white light with Improved efficiency and stability

A device and organic technology, applied in the field of organic light-emitting devices, can solve the problems of low dopant concentration and difficult process control, and achieve the effect of low driving voltage and high operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] OLED devices were fabricated using the following methods:

[0106] The substrates coated with 80 nm ITO were sequentially ultrasonically cleaned in a commercial detergent, rinsed in deionized water, and degreased in toluene vapor. These substrates were treated with oxygen plasma for about 1 min, and plasma-assisted deposition of CHF 3 A 1 nm layer of fluorocarbon is applied. This same method was used to prepare all other devices described in this invention.

[0107] These substrates are loaded into the deposition chamber for the deposition of organic layers and cathodes.

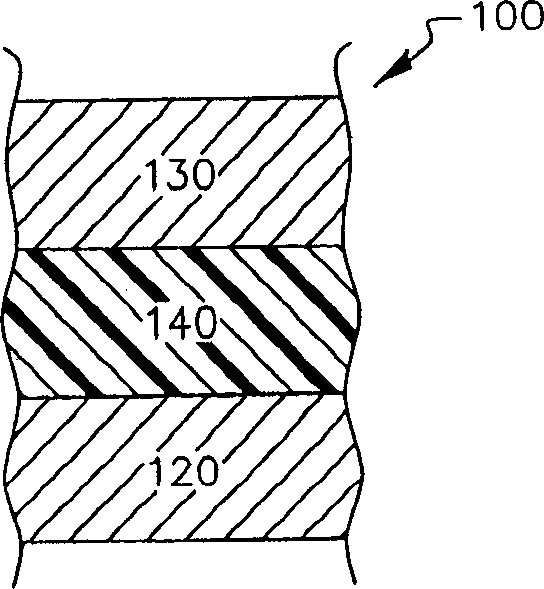

[0108] The making of device A is to deposit 150nm NPB hole transport layer (HTL) sequentially, 20nm blue light-emitting layer (EML), this layer comprises the ADN matrix containing 1.5% TBP blue dopant, 37.5nm Alq electron transport layer (ETL ), followed by 0.5 nm LiF and 200 nm Al as part of the cathode. The above process completes the deposition of the OLED device.

[0109] Then the OLED device...

Embodiment 2

[0115] OLED devices G, H, I, J, K, and L were fabricated by inserting undoped NPB between the rubrene-doped NPB hole transport layer 341a and the blue light-emitting layer 342 .

[0116] Table 2: White OLEDs with rubrene-doped NPB HTL and blue light-emitting layer at defined positions

Device#

HTL layer

NPB undoped

layer

blue light emitting layer

send layer

cathode

driving voltage

(V)

Luminous efficiency

(cd / A)

CIEx

CIE

color

G

120 nm NPB Undoped / 30 nm NPB

+1.5% rubrene doped

0 nm

20 nmADN+1.5%

TBP

35 nm Alq

200 nm MgAg

8.5

4.54

0.359

0.399

White

H

118 nm NPB undoped / 30 nm NPB+

1.5% rubrene doped

2 nm

20 nmADN+1.5%

TBP

3...

Embodiment 3

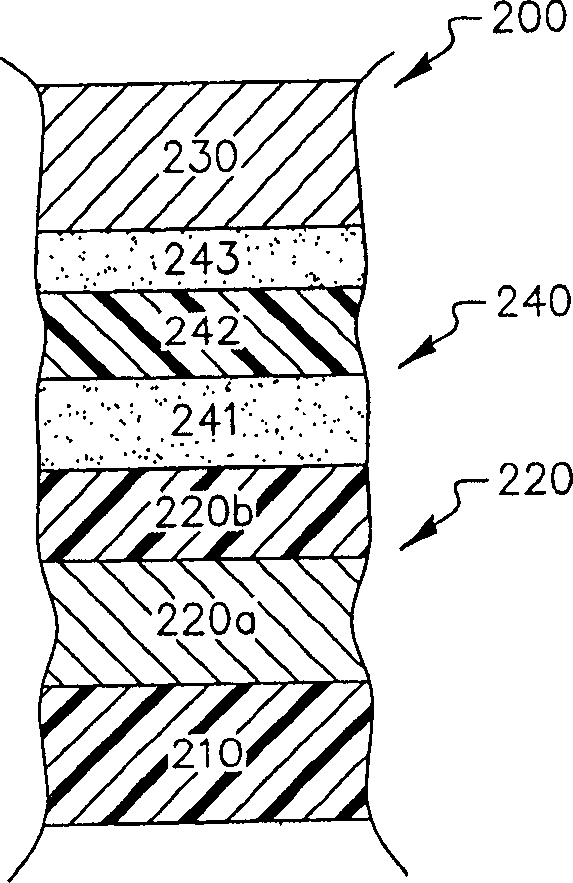

[0120] according to Figure 7 Devices M to R were fabricated with the structure shown. The deposition sequence is the same as that of device A, except that the first 20 nm Alq electron transport layer 243a is doped with different concentrations of rubrene: (M) 0.0%, (N) 0.3%, (O) 0.5%, (P ) 1%, (Q) 2%, (R) 5%. The rubrene-doped Alq layer was followed by a 15 nm undoped Alq layer 343 so that the total thickness of the rubrene-doped Alq and undoped Alq layers was equal to 37.5 nm. Device M was found to have an emission in the blue region of the electromagnetic spectrum, while the emissions of devices N and O were shifted towards blue-white. Devices P, Q and R emit white. Therefore, the Alq electron transport layer and the blue light-emitting layer doped with the optimal concentration of rubrene can generate white light.

[0121] Figure 8 EL spectra are shown for devices M to R where the concentration of rubrene in the electron transport layer was varied between 0 and 5%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com