Process for preparing compound forming phase changing material of polyethyldiol/silicon dioxide

A technology of shape-setting phase change material and polyethylene glycol, which is applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of easy crushing of porous substrates, deformation and shapeability, and high porosity, and achieves high latent heat, high Good setting performance and uniform dispersion of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

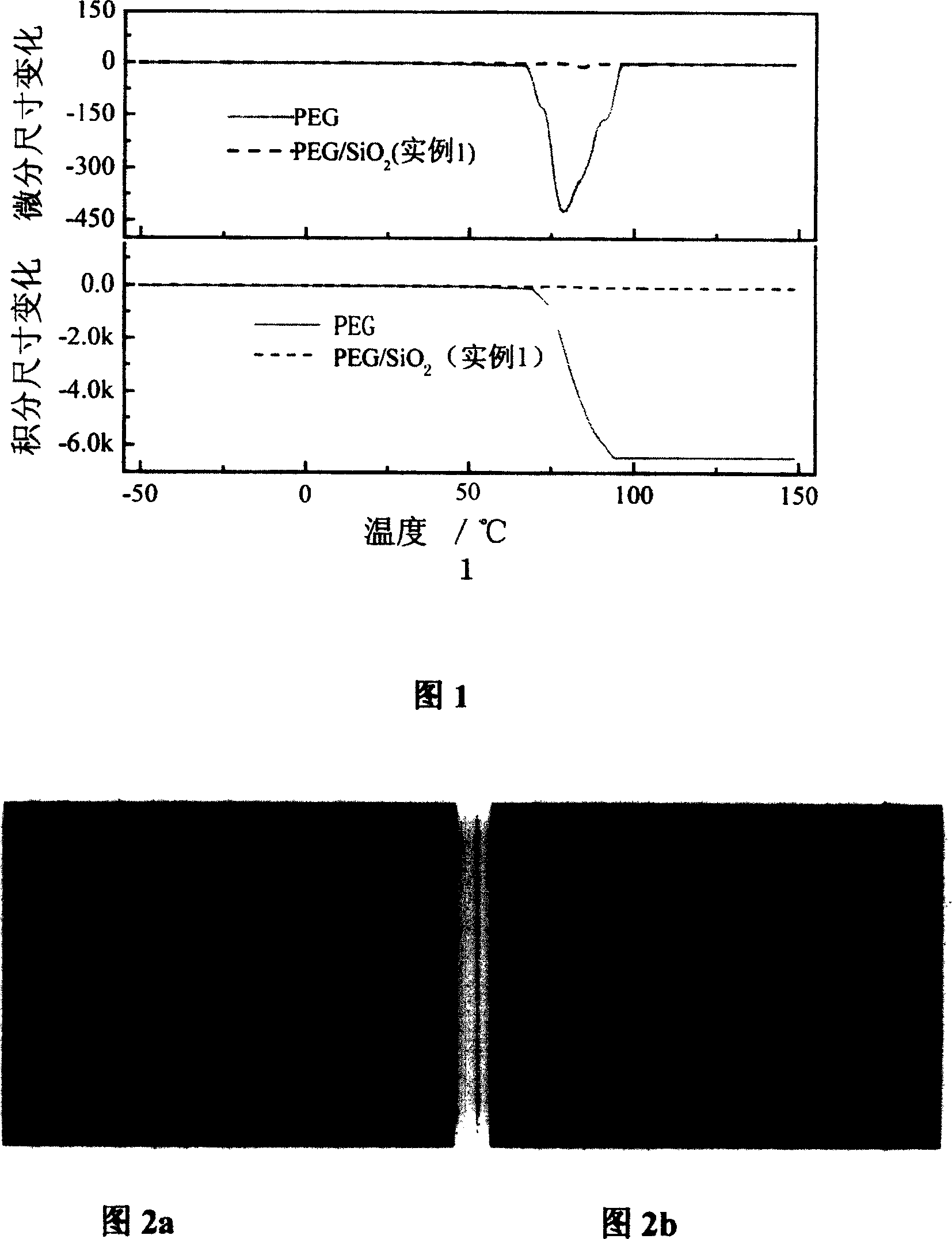

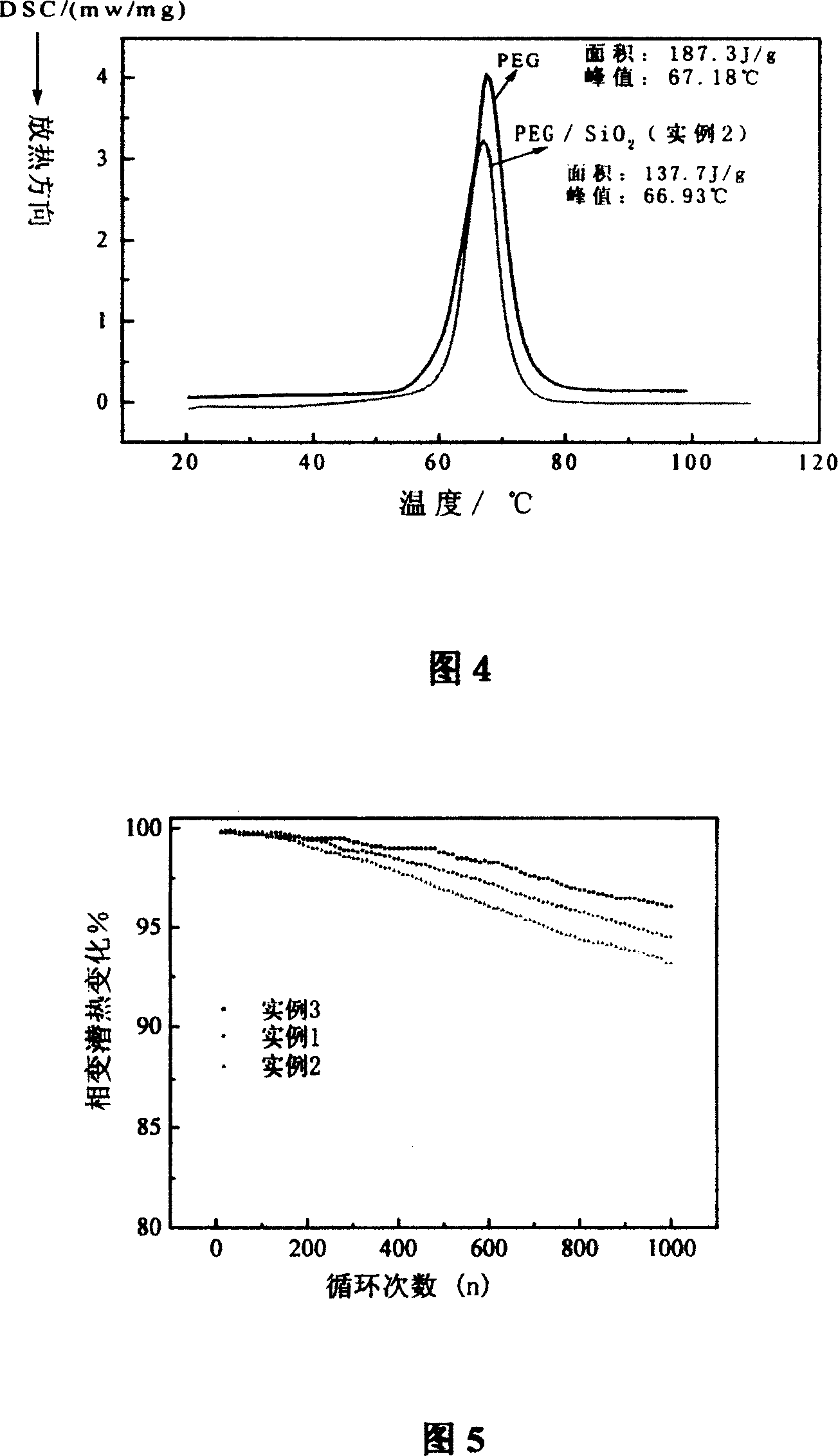

Embodiment 1

[0031] Steps: (1) At room temperature, in a 1.5L glass beaker, add 500g of 20% silica sol (pH value = 9), and slowly add polyethylene glycol (PEG5000 / PEG10000 = 1 / 2) under vigorous stirring by a CNC mixer 400g of powder, after the polyethylene glycol powder is completely dissolved, slowly add 1% aluminum sulfate solution dropwise according to the ratio of 0.01‰ of the total amount of composite phase-change and shape-setting materials, and continue stirring until all gels are formed. Transfer the beaker containing the gel into a blast drying oven, dry at a constant temperature of 80°C for 36 hours, cool to room temperature, take out the dried gel, mash it in a mortar, transfer it to a beaker, and stir it vigorously to obtain Powder. (2) Transfer the powder into a 1L four-necked flask equipped with a stirrer, nitrogen tube, reflux tube, and dropping funnel, and vacuumize at 40°C for 3 hours while stirring, then heat the oil bath to 90°C, and open the water condensation return pi...

Embodiment 2

[0038] Steps: (1) In a 1.5L glass beaker, add 600g of 15% silica sol (pH value = 8), and slowly add 360g of polyethylene glycol (PEG5000 / PEG10000 = 1 / 1) powder under vigorous stirring by a CNC mixer, and wait until After the polyethylene glycol powder is completely dissolved, slowly add 0.1M acetic acid dropwise at a ratio of 0.05‰ of the total amount of the composite phase change shape-setting material, and continue to stir until all the materials are gelled. Transfer the beaker containing the gel into a blast drying oven, dry at a constant temperature of 80°C for 48 hours, cool to room temperature, take out the dried gel, mash it in a mortar, transfer it to a beaker, and stir it vigorously to obtain Powder;

[0039] (2) Transfer the powder into a 1L four-necked flask equipped with a stirrer, nitrogen tube, reflux tube, and dropping funnel, and vacuumize at 40°C for 3 hours while stirring, then heat the oil bath to 90°C, and open the water condensation return pipe , Nitrogen...

Embodiment 3

[0041] Steps: (1) at room temperature, in a 1.5L glass beaker, add 500g of 30% silica sol (pH value=8.5), and slowly add polyethylene glycol ((PEG3000 / PEG15000=1 / 2 )) powder 350g, after the polyethylene glycol powder is completely dissolved, slowly add 1% calcium chloride solution dropwise according to the ratio of 0.03‰ of the total amount of the composite phase change shape-setting material, and continue to stir until it is completely gelled. Transfer the beaker containing the gel into a blast drying oven, dry at a constant temperature of 80°C for 24 hours, cool to room temperature, take out the dried gel, mash it in a mortar, transfer it to a beaker, and stir it vigorously to obtain Powder.

[0042] (2) Transfer the powder into a 1L four-necked flask equipped with a stirrer, nitrogen tube, reflux tube, and dropping funnel, and vacuumize at 40°C for 3 hours while stirring, then heat the oil bath to 90°C, and open the water condensation return pipe , nitrogen protection, acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com