Method of preparing ethylenediamine tetracetonitrile and ethylenediamine tetraacetic acid using hydroxy acetonitrile as raw material

A technology of ethylenediaminetetraacetonitrile and ethylenediaminetetraacetic acid, applied in the field of preparation of ethylenediaminetetraacetonitrile, can solve the problems of low price, high cost and poor safety of chloroacetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

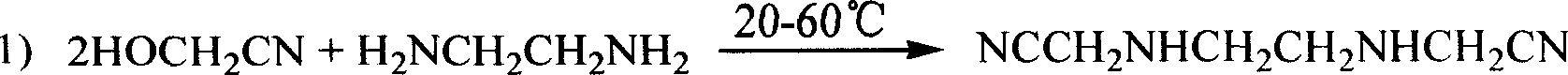

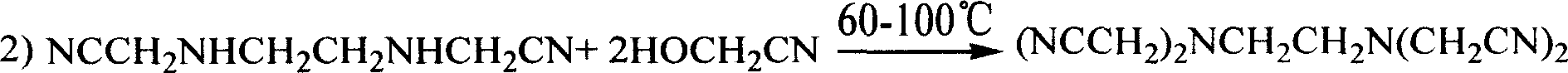

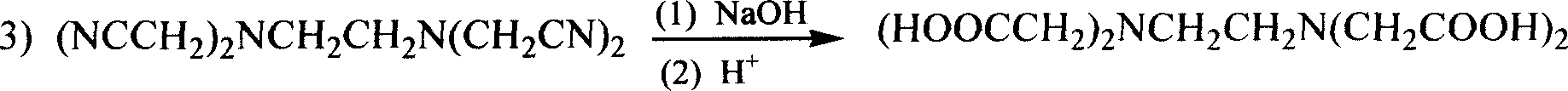

Method used

Image

Examples

Embodiment 1

[0022] In a three-neck round bottom flask equipped with a thermometer, reflux condenser, and constant pressure dropping funnel, adjust the pH of 6.7ml (6g, 0.1mol) of ethylenediamine solution to 6-8 with concentrated hydrochloric acid, and add it dropwise at room temperature 30ml (0.2mol) of hydroxyacetonitrile, the temperature was raised to 40°C-50°C, and the temperature was kept at 20°C-60°C for more than 30min (dropping and reacting for 1 hour). Heat up to 60°C-100°C, add 34ml (0.24mol) of hydroxyacetonitrile dropwise, react at 60°C-100°C for 3 hours, add saturated NaHCO 3 The pH was adjusted to about 6, and the reaction was continued for 3 hours. After cooling, suction filtration, washing and drying, EDTN was obtained, 18.4g (85% yield), with a melting point of 132-134°C. The product was confirmed by NMR and IR.

[0023] Dissolve 5.4g (25mmol) of EDTN obtained above in 10.3ml of 30% NaOH solution, stir at 40°C for 30min, heat to a slight boil, drive out most of the ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com