Preparing method of high voltage vacuum arc-extinguishing room contact material

A vacuum interrupter and contact material technology, applied in the field of vacuum interrupter, can solve the problems of breaking capacity, anti-welding ability, high pressure resistance, insufficient arc resistance, atmospheric ozone layer destruction, living environment hazards, etc. , to achieve the effects of good arc extinguishing performance, easy production scale, and good arc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

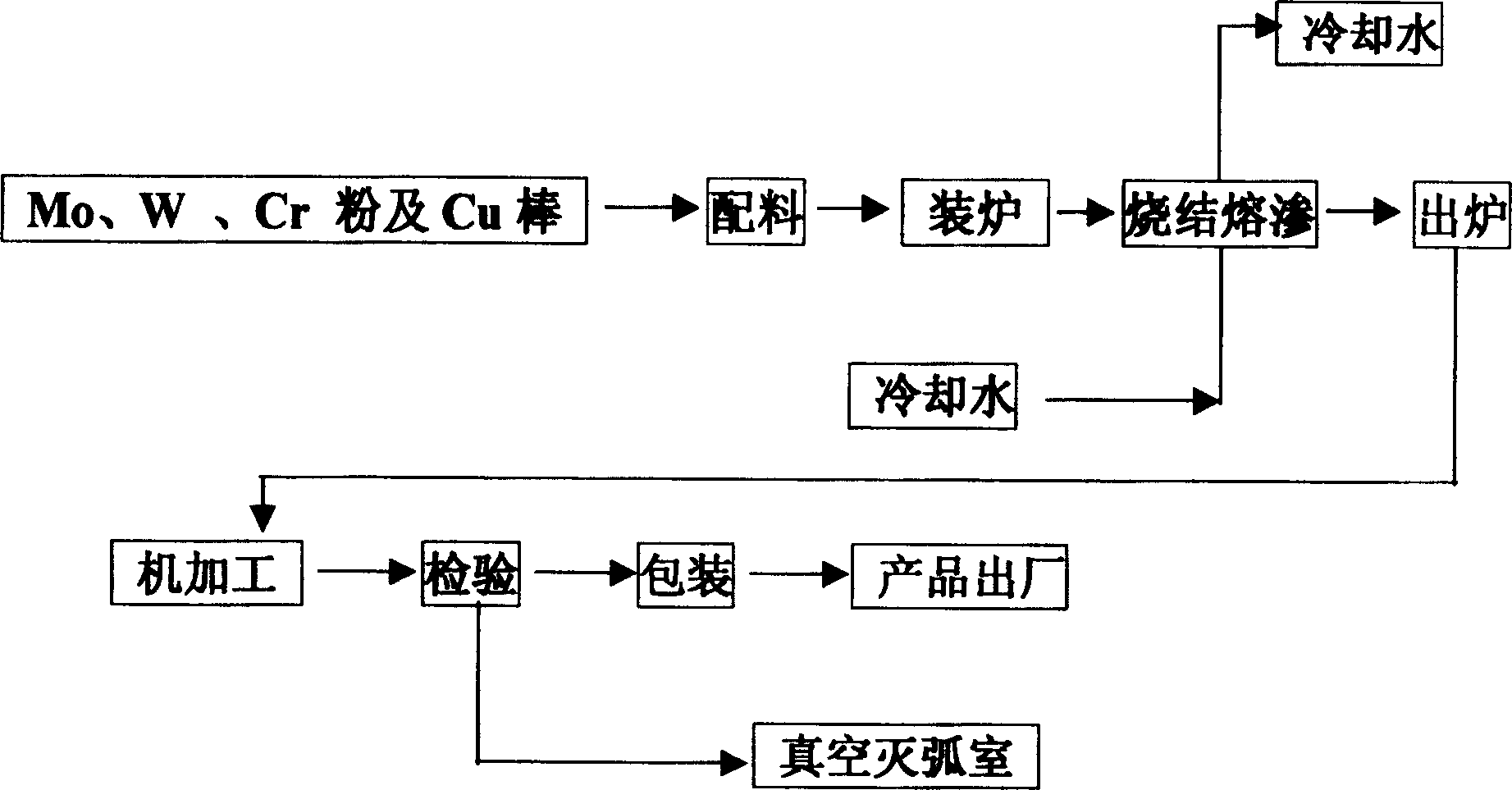

Method used

Image

Examples

Embodiment 1

[0019] The contact material of the high-voltage vacuum interrupter of the present invention is composed of ingredients according to the following weight percentages:

[0020] Mo, W, and Cr passed through a 100-mesh sieve were 20.35%, 4.66%, 4.67%, and Cu rods 70.32%.

[0021] Put the uniformly mixed Mo, W and Cr powders into a crucible with graphite paper, put the weighed copper rod into the crucible cap, fix the crucible on the tray, and place the crucible cap on the crucible. Close the furnace cover, evacuate to 0.02Mpa, raise the temperature to 100°C, and keep it warm for 30 minutes; then raise the temperature to 1300°C, and keep it warm for 30 minutes to carry out infiltration treatment under the condition that the vacuum degree is guaranteed to be 0.02Mpa; then turn off the heating system and cool down to 1200°C ℃, keep warm for 60 minutes; continue to cool down to get the product out of the oven, and get the finished product after mechanical processing and other post-pro...

Embodiment 2

[0025] The contact material of the high-voltage vacuum interrupter of the present invention is composed of ingredients according to the following weight percentages:

[0026] The Mo, W, and Cr passed through a 120-mesh sieve are 20%, 5%, and 5%, respectively, and the Cu rods are 70%.

[0027] Put the uniformly mixed Mo, W and Cr powders into a crucible with graphite paper, put the weighed copper rod into the crucible cap, fix the crucible on the tray, and place the crucible cap on the crucible. Close the furnace cover, evacuate to 0.02Mpa, raise the temperature to 105°C, and keep it warm for 35 minutes; then raise the temperature to 1310°C, and keep it warm for 30 minutes to carry out infiltration treatment under the condition that the vacuum degree is guaranteed to be 0.02Mpa; then turn off the heating system and cool down to 1210°C ℃, keep warm for 55 minutes; continue to cool down to get the product out of the oven, and get the finished product after mechanical processing a...

Embodiment 3

[0029] The contact material of the high-voltage vacuum interrupter of the present invention is composed of ingredients according to the following weight percentages:

[0030] The Mo, W, and Cr passed through a 110-mesh sieve are 20%, 5.5%, 4.5%, and 70% of Cu rods.

[0031] Put the uniformly mixed Mo, W and Cr powders into a crucible with graphite paper, put the weighed copper rod into the crucible cap, fix the crucible on the tray, and place the crucible cap on the crucible. Close the furnace cover, evacuate to 0.023Mpa, raise the temperature to 110°C, and keep it warm for 30 minutes; then raise the temperature to 1320°C, and keep it warm for 30 minutes to carry out infiltration treatment under the condition that the vacuum degree is guaranteed to be 0.022Mpa; then turn off the heating system and cool down to 1190°C ℃, keep warm for 65 minutes; continue to cool down to get the product out of the oven, and get the finished product after mechanical processing and other post-pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com