Method for producing bearing shell material of nano composite aluminium base

A nano-composite and manufacturing method technology, applied in the field of manufacturing nano-composite aluminum-based bearing materials, can solve problems such as the inability to obtain a uniformly dispersed Pb alloy structure, high power requirements for work-hardening rolling mills, and difficulty in effective hot-rolling and compounding. Achieve the effects of enhanced wear resistance, low cost, and improved coating bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

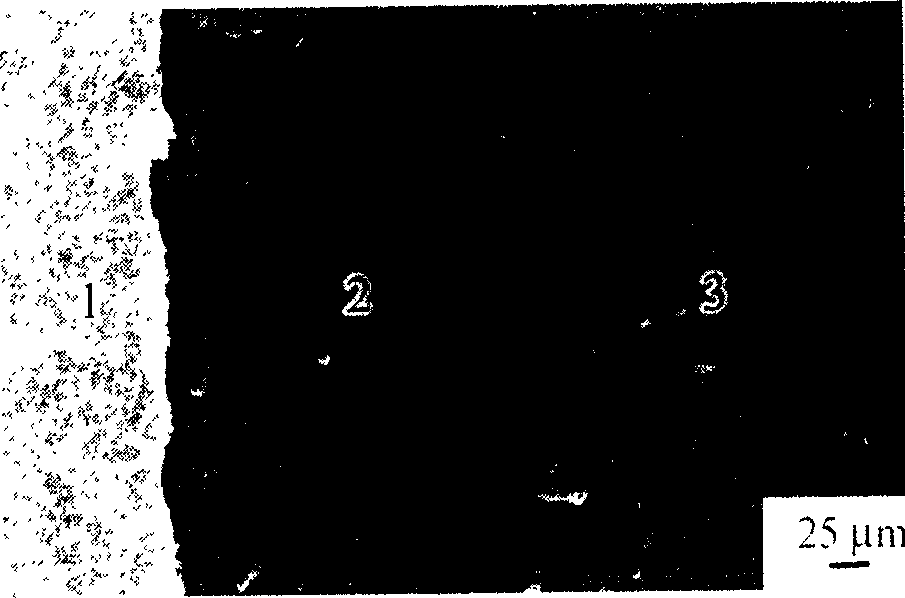

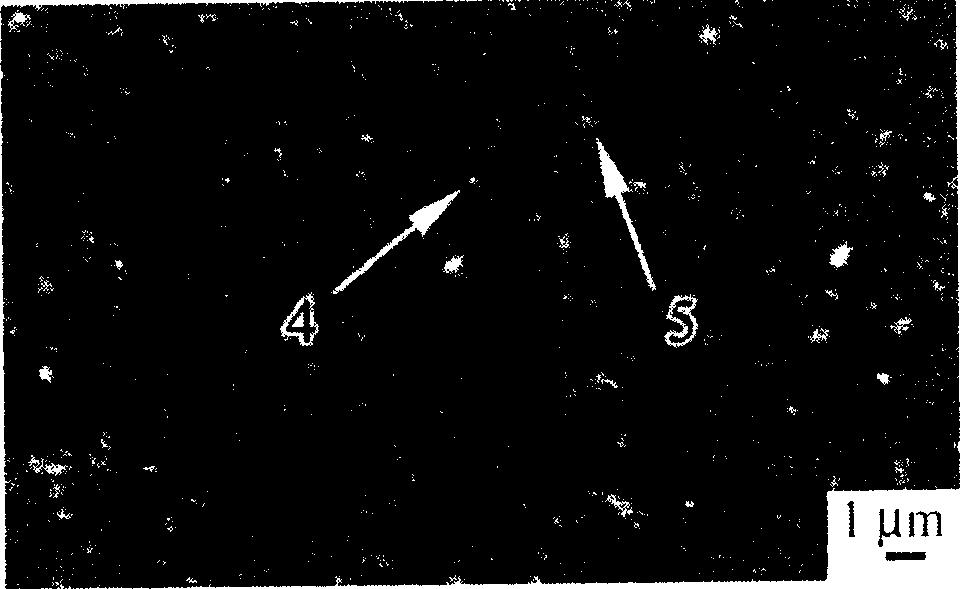

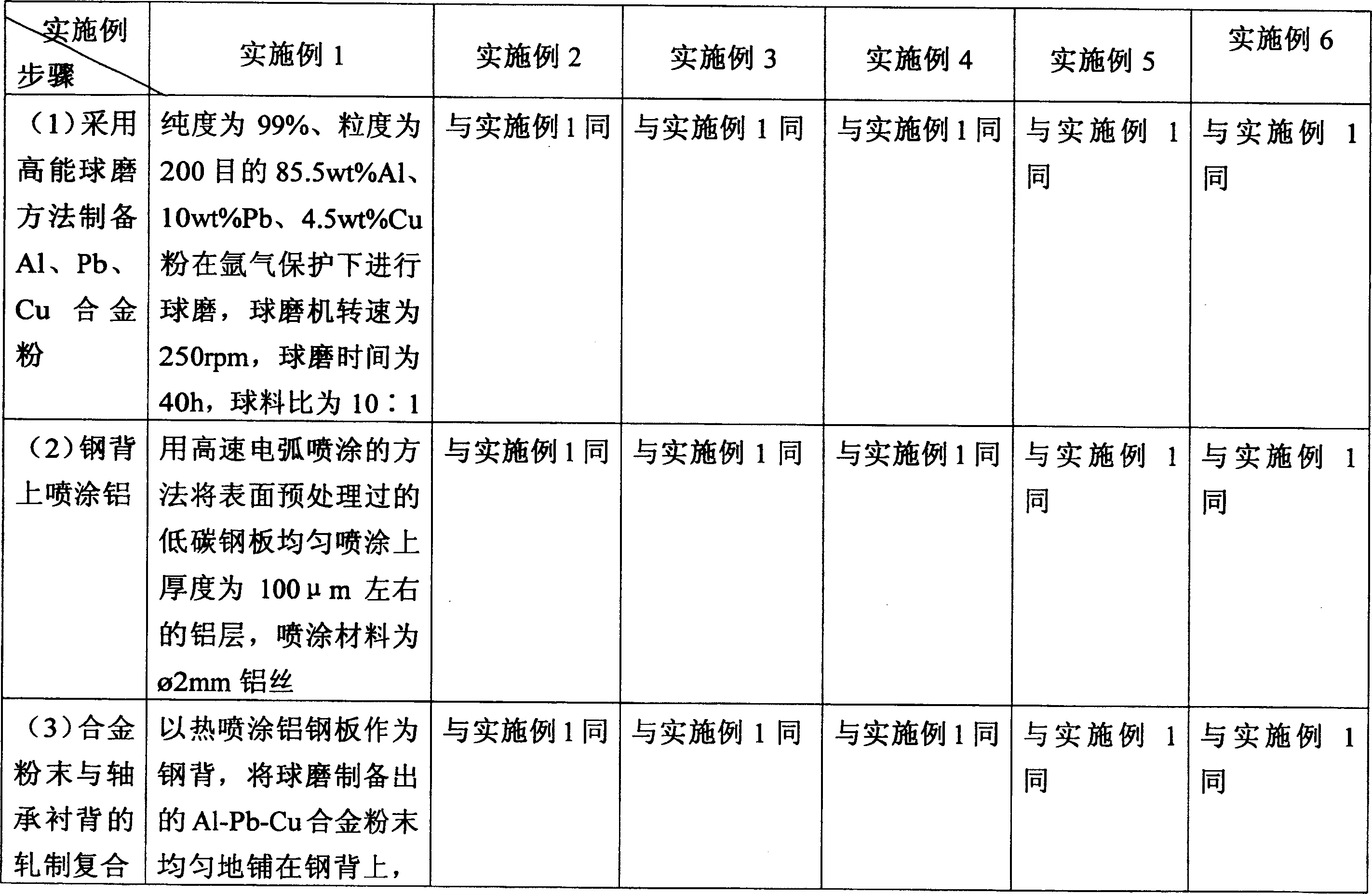

[0023] The scanning electron micrograph (SEM) of the Al-Pb-Cu bearing alloy that embodiment 2 manufactures is as figure 1 As shown in the figure, 1 is the steel plate, 2 is the thermal sprayed Al layer, and 3 is the Al-Pb-Cu alloy layer. It can be seen that the Al-Pb-Cu alloy layer has been well combined with the thermal sprayed Al steel back to form a A "sandwich" sandwich structure, and the rolling layer structure is uniform and dense. figure 2 yes figure 1 The enlarged scanning electron microscope photo of the Al-Pb-Cu alloy layer in the middle, it can be seen from the figure that the Pb phase (ie 4) is uniformly dispersed in the aluminum matrix, and many finer particles that cannot be distinguished are dispersed on the matrix. Pb particles, the off-white area is CuAl 2 Phase enrichment zone (ie 5).

Embodiment 1

[0024] The Al-Pb-Cu bearing alloys produced in Example 1, Example 3, Example 4, Example 5 and Example 6 have uniform and dispersed distribution, and the hardness value is between Hv55 and 80. The casting method and powder metallurgy method The hardness of aluminum-based bearing alloys is only between Hv30 and 50, so the hardness of nano-composite Al-Pb-Cu bearing alloys is more than twice that of ordinary aluminum-based bearing alloys. Under the conditions of load 196N, speed 400r / min, and dry friction, the wear time is 1 hour. The wear performance of the material is shown in Table 2.

[0025] Table 1

[0026]

[0027] The thickness is about 4mm, press

[0028] Compostion

[0029] It can be seen from Table 2 that the wear amount of the Al-Pb-Cu bearing alloy prepared by mechanical alloying is significantly lower than that of the Al-Pb alloy obtained by the P / M method and the Stricast method, and the wear resistance of the alloy has been greatly improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com