Catalyst concentration and proportion controlling method for p-xylene oxidizing reaction

A technology of catalyst concentration and oxidation reaction, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, reagents, etc., can solve problems such as increased ash content, increased combustion reaction products, difficult filter operation, etc., and achieves good product quality and low unit consumption Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

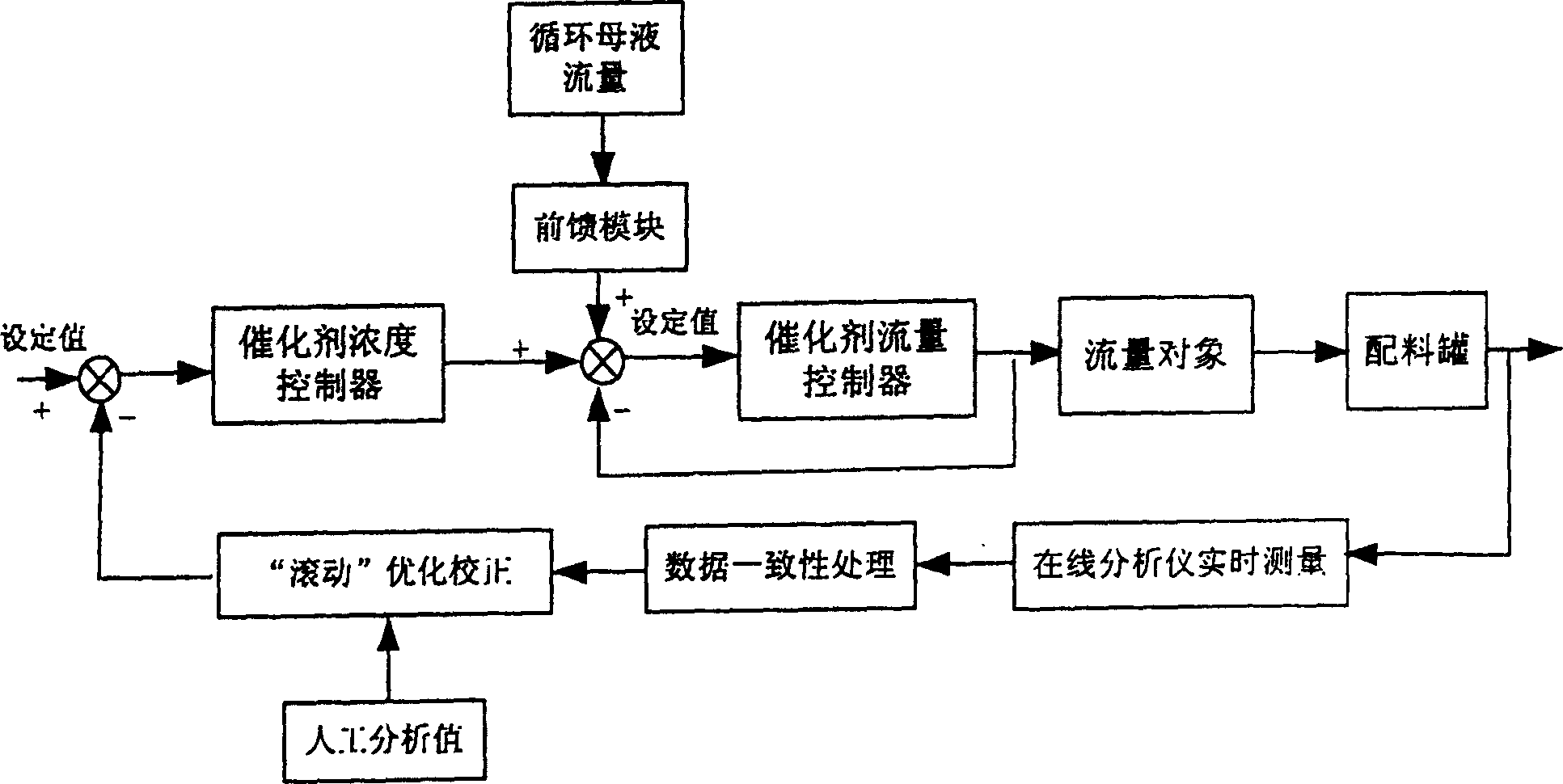

Method used

Image

Examples

Embodiment Construction

[0016] 1. Design and installation of process filter

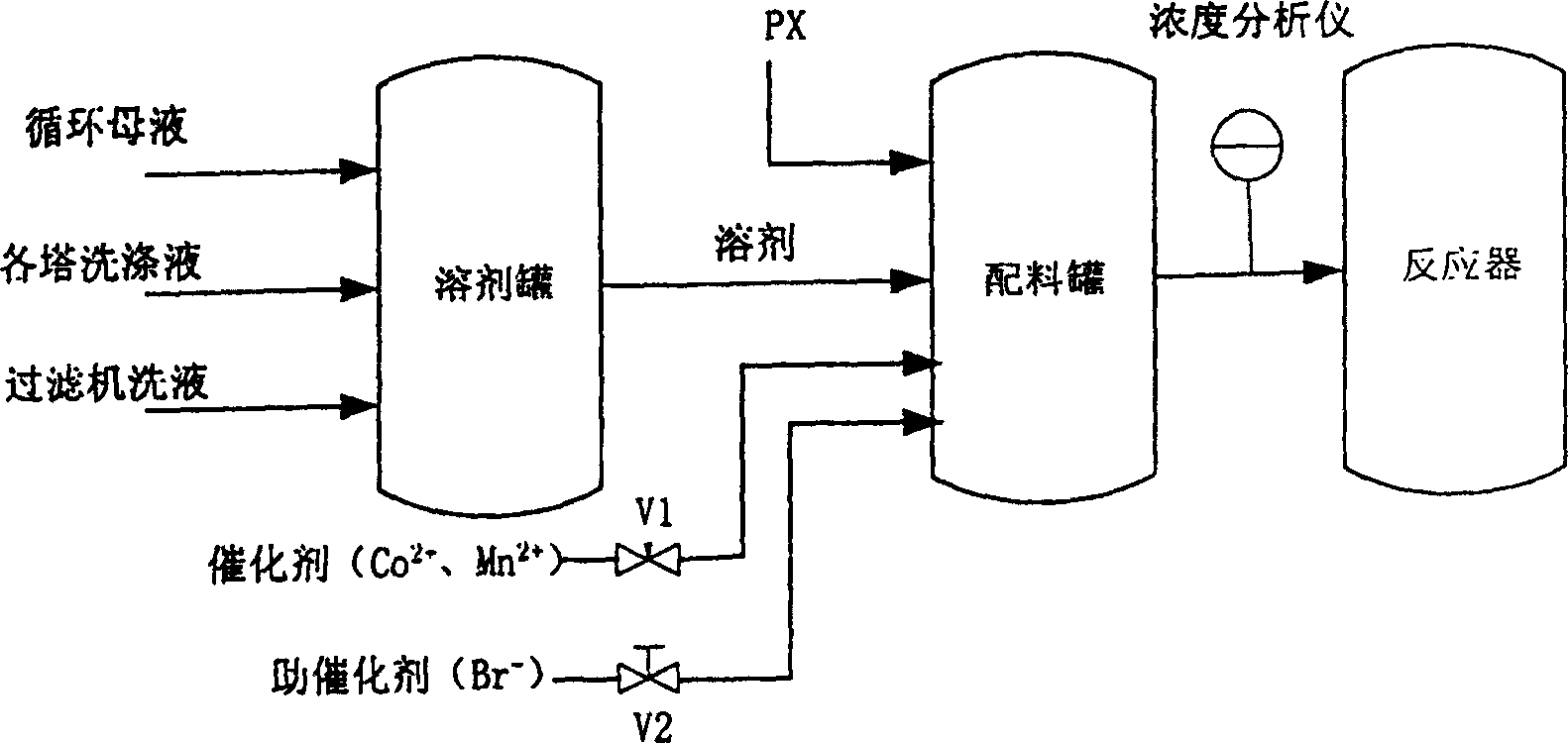

[0017] The mother liquor separated from the PTA slurry after filtration contains a certain amount of PTA solids (referred to as mother solids). It is of great significance to recycle this part of the mother solids from an economic or environmental point of view. Therefore, almost all PTA plants Both are equipped with a parent solid material recovery unit to circulate the PTA parent solid material back to the feed of the oxidation unit as a raw material for reuse.

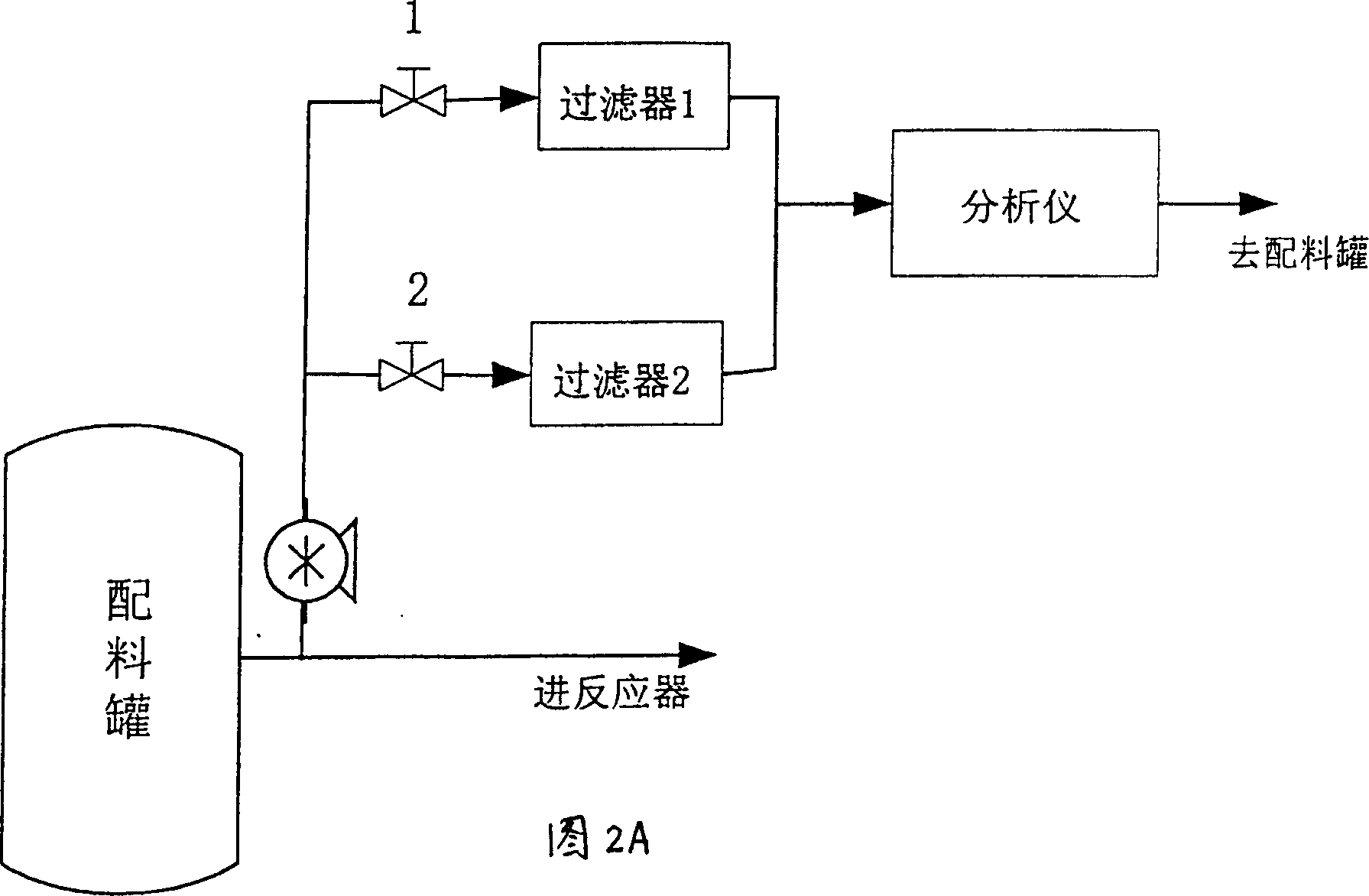

[0018] However, it is precisely because of the circulation of the parent solid material that the solid content in the reactor feed is relatively high, so that when passing through the filter pretreatment unit of the analyzer, the large particle slurry is blocked at the sampling port, resulting in the failure of the analyzer to perform normal operations. sampling. In order to ensure the normal operation of the online analyzer, such as figure 2 As shown, a Y-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com