A transmission control device and method for ear glue and nickel transfer belt

A technology of conveying control and transferring nickel belts, applied in electrode manufacturing, sending objects, transportation and packaging, etc., can solve the problems of difficulty in popularization, transformation and installation, labor-intensive labor, and many scrapped materials, etc., to solve the problem of automatic control , The effect of reducing the workload of workers and the large workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The transmission control device of the tab glue and the nickel belt of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

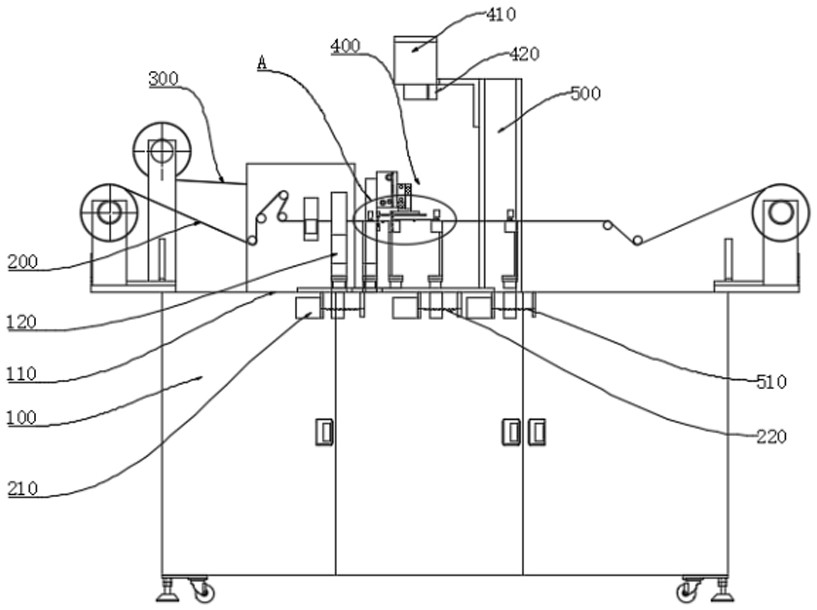

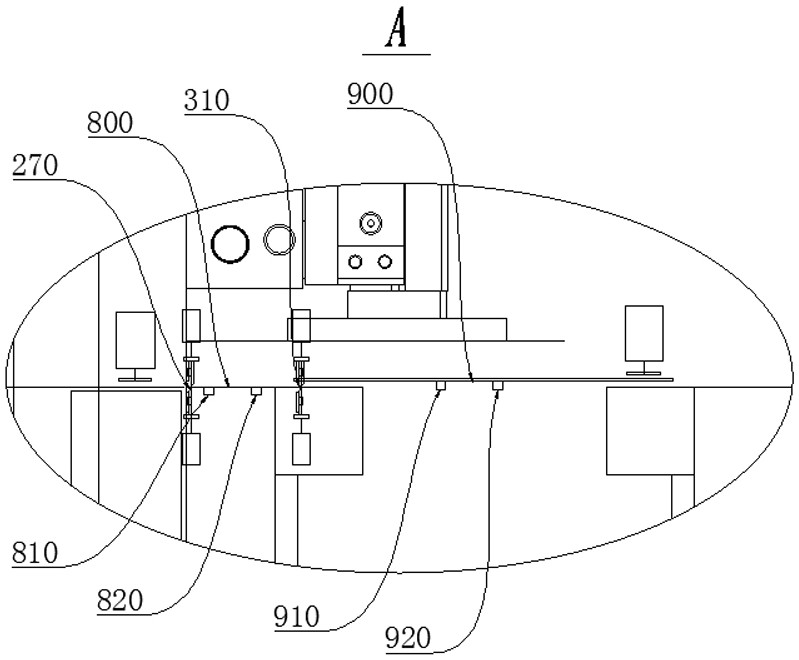

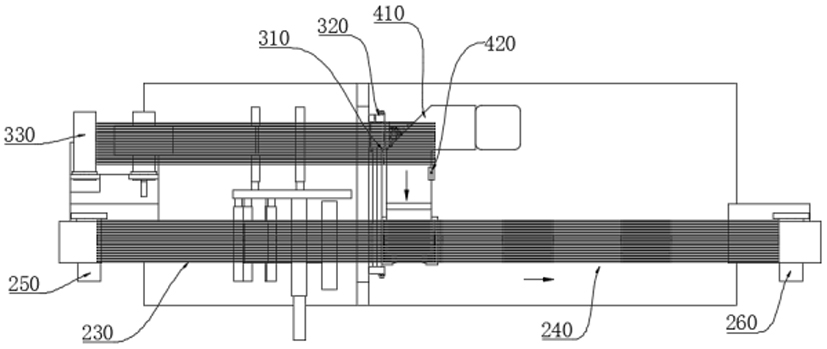

[0029] refer to figure 1 and figure 2, a non-limiting embodiment of the present invention, a transmission control device for tab glue and nickel transfer belt, including a cabinet 100 and a PLC control system, the top of the cabinet 100 is a workbench 110, and the workbench 110 is provided with Frame 120, the top of the frame 120 is provided with a master tape transmission line 200 and a sub-tape transmission line 300. The top of the transmission line 200 is provided with a transfer welding station 400 and a tape thermal lamination station 500 in sequence. A sub-tape cutting mechanism 310 is provided below, and an adapter sub-tape clamping mechanism 320 for transferring the sub-tape to the master tape is provided below the output end of the sub-tape transmission lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com