Fine particulate oxide composition containing titanium oxide, and preparing method and use thereof

A technology containing titanium oxide and a manufacturing method, which is applied in the directions of titanium oxide/hydroxide, titanium dioxide, chemical instruments and methods, etc., can solve the problems of long process and infeasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

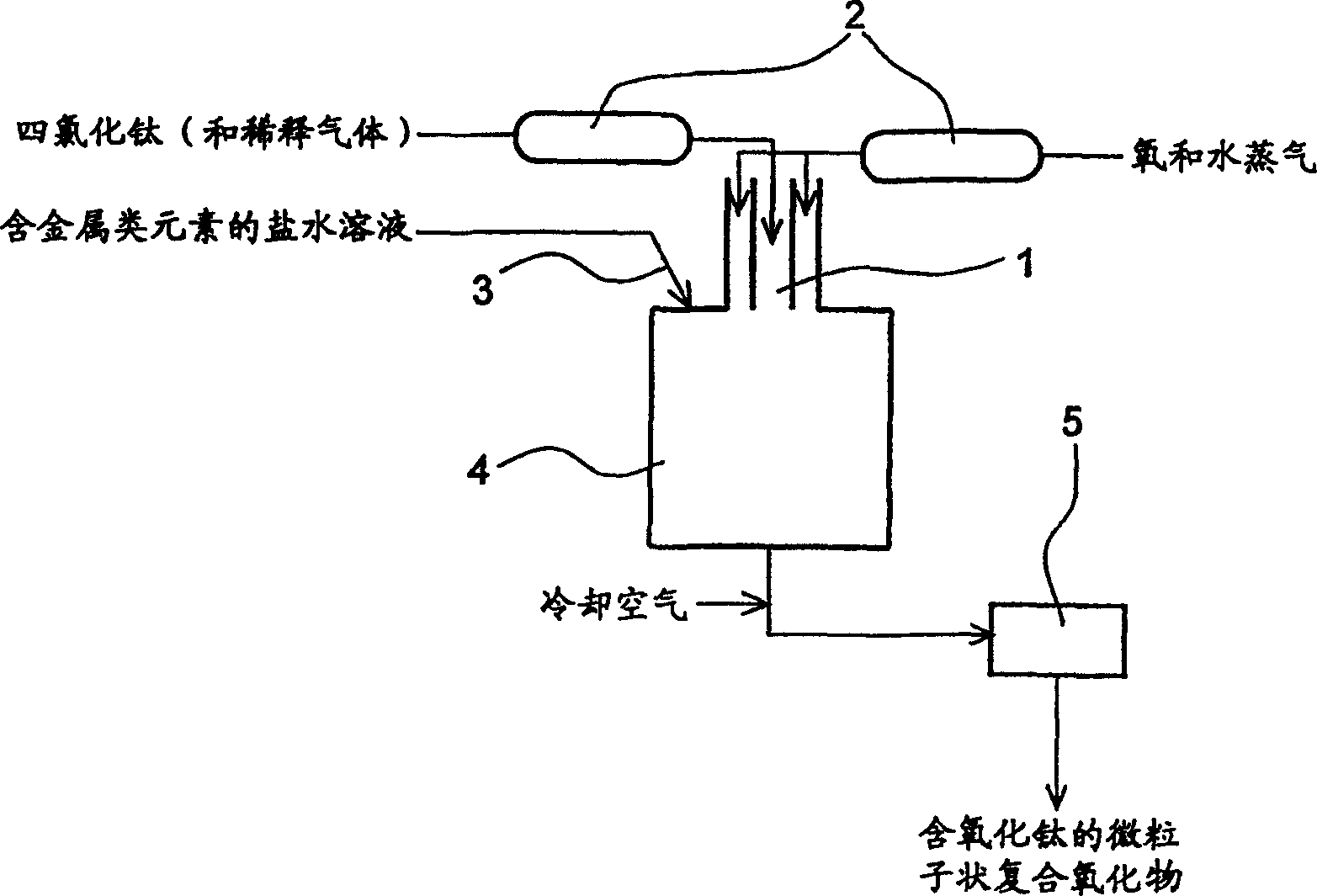

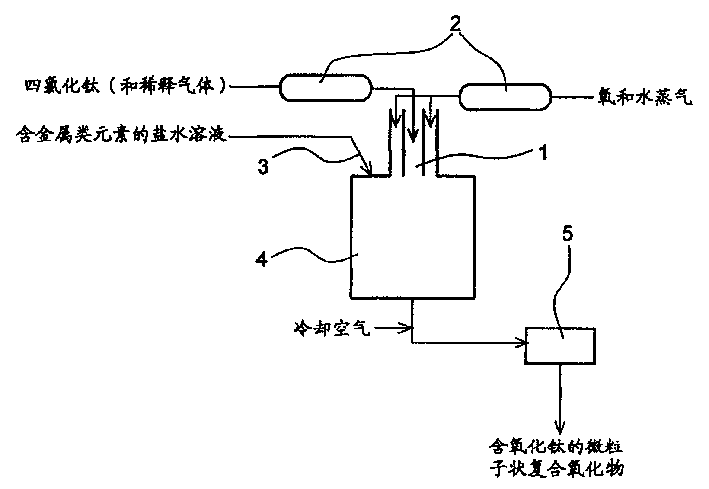

[0093] use figure 1 The coaxial parallel flow nozzle shown has a reaction tube with an inner diameter of 20 mm.

[0094] Gas-like titanium tetrachloride 11.8Nm containing 100% by volume 3 / hour (N refers to the standard state. The same below) preheat to 1100 ℃, put 8Nm 3 / hour of oxygen and 20Nm 3 The mixed gas of water vapor per hour is preheated to 1000°C, and the titanium tetrachloride is introduced into the inner tube of the coaxial parallel flow nozzle at the flow speed of 53m / s and 50m / s respectively, and oxygen and water vapor are introduced into the outer tube. mixed composition. In addition, 3.7 kg / hour of a 20% aqueous solution of zirconium oxychloride was sprayed from the outer peripheral portion of the coaxial parallel flow nozzle.

[0095] The calculated value of the flow velocity in the tube at a reaction temperature of 900° C. in the reaction tube was 10 m / sec. After the reaction was carried out so that the high-temperature residence time in the reaction t...

Embodiment 2

[0099] use as figure 1 The inner pipe diameter of the coaxial parallel flow nozzle shown is a reaction tube of 20mm, and the gaseous titanium tetrachloride 10.6Nm 3 / hour and nitrogen 6.0Nm 3 / hour of gas mixed to form the raw material gas containing titanium tetrachloride preheated to 1,100 ° C, 8Nm 3 / hour of oxygen and 30Nm 3 The mixed gas of water vapor per hour is preheated to 1,100°C, and the gas containing titanium tetrachloride is introduced into the inner tube of the coaxial parallel flow nozzle at the flow rate of 74m / s and 66m / s respectively, and oxygen and oxygen are introduced into the outer tube. Mixture of water vapor. In addition, 7.1 kg / hour of a 20% aqueous solution of chromium trichloride was sprayed from the outer peripheral portion of the coaxial parallel flow nozzle.

[0100] The calculated value of the flow velocity in the tube at a reaction temperature of 1,000° C. in the reaction tube was 10 m / sec. After the reaction was carried out so that the hi...

Embodiment 3

[0103] use as figure 1 The inner pipe diameter of the coaxial parallel flow nozzle shown is a reaction tube of 24mm, and the gaseous titanium tetrachloride 10.6Nm 3 / hour and nitrogen 10.0Nm 3 / hour of gas mixed to form the raw material gas containing titanium tetrachloride preheated to 1,050 ° C, 8Nm 3 / hour of oxygen and 30Nm 3 The mixed gas of water vapor per hour is preheated to 1,100°C, and the gas containing titanium tetrachloride is introduced into the inner tube of the coaxial parallel flow nozzle at the flow rate of 64m / s and 36m / s respectively, and oxygen and oxygen are introduced into the outer tube. Mixture of water vapor. In addition, 6.5 kg / hour of a 20% aqueous solution of magnesium nitrate was sprayed from the outer peripheral portion of the coaxial parallel flow nozzle.

[0104] The calculated value of the flow velocity in the tube at a reaction temperature of 1,000° C. in the reaction tube was 10 m / sec. After the reaction was carried out so that the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com