Component for aluminum die-casting die

An aluminum die-casting and mold technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of poor dimensional accuracy, reduced wear resistance, unable to maintain long-term inhibition of aluminum alloys and substrates, etc., to achieve excellent The effect of sintering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

[0021] Hereinafter, a member for an aluminum die-casting die (hereinafter, may be referred to as a “first member”) according to a first embodiment of the present invention will be described with reference to the drawings.

[0022]

[0023] The first member has an exposed surface that is a surface exposed in the cavity of the aluminum die-casting mold. In addition, "aluminum die casting" in this specification includes not only the die casting method of aluminum but also the die casting method of aluminum alloy. In addition, the first member is not particularly limited as long as it has an exposed surface that is a surface exposed in the cavity of the aluminum die-casting mold. Specific examples of such members include, for example, members constituting a cavity or a core of an aluminum die-casting mold, and members such as casting pins.

[0024] The material of the base material constituting the first member can be appropriately selected from various materials generally used...

no. 2 approach 》

[0035] Hereinafter, the member for aluminum die-casting molds (it may be called a "2nd member" hereafter) which concerns on 2nd Embodiment of this invention is demonstrated.

[0036]

[0037]As described above, according to the first member, since the diamond-like carbon (DLC) film formed on at least a part of the exposed surface contains hydrogen at a predetermined content rate, the film can have both good toughness and wear resistance, and maintain Resistance to sintering relative to molten metals containing aluminum. However, depending on the conditions of the die casting process (for example, the temperature of molten metal, etc.), oxidation (combustion) of carbon and hydrogen constituting the DLC film may occur. As a result, the heat resistance (oxidation resistance) of the coating becomes insufficient, and it may be difficult to maintain the seizing resistance to molten metal containing aluminum for a long period of time.

[0038] Therefore, the second member is a mem...

Embodiment

[0046] "Preparation of various samples"

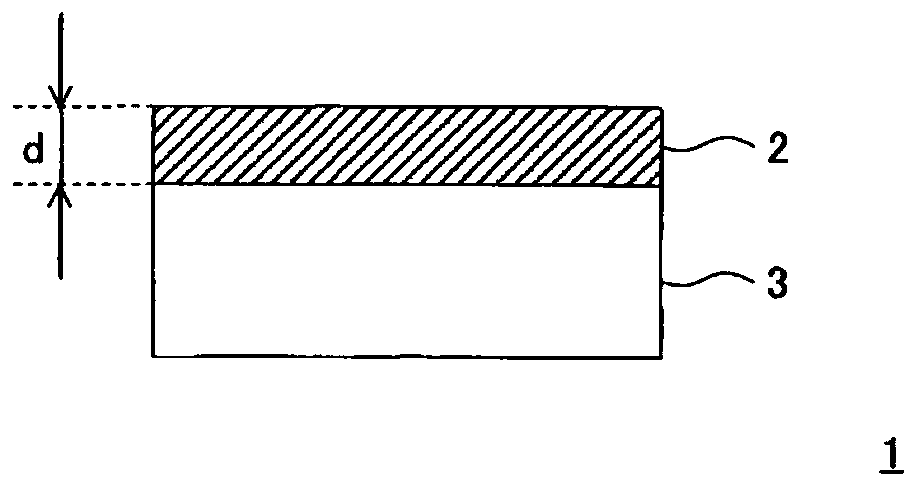

[0047] Hereinafter, parts for aluminum die-casting molds according to embodiments of the present invention will be described in detail with reference to the drawings. A test piece and a cast pin made of alloy tool steel SKD61 for molds were prepared, and the coatings listed in Table 1 below were formed on the respective surfaces. For any sample, the same as figure 1 In each case shown, each coating was formed so that the thickness (d) of the coating became about 3 μm. should be explained, figure 1 It is a schematic cross-sectional view of the surface (exposed surface) on which the coating is formed in each sample (1) near the coating, and depicts the coating (2) and a part of the substrate (3) of the sample (1).

[0048] [Table 1]

[0049]

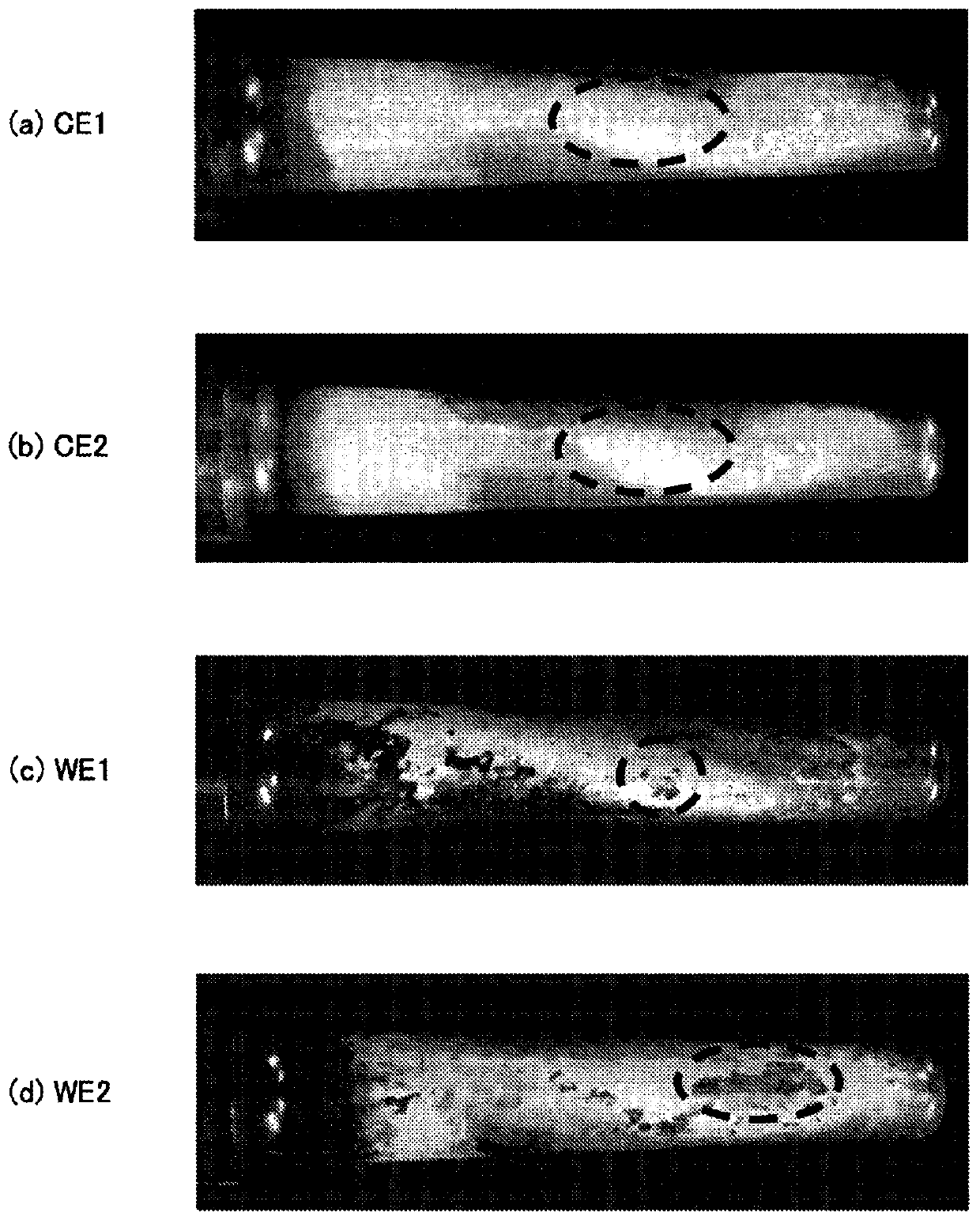

[0050] As shown in Table 1, for sample CE1 of the comparative example, a nitride film was formed on the surface of the test piece and the casting pin by the salt bath nitriding method (the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com