Tundish dry working lining with anti-swelling and cracking and preparation method thereof

A working lining and anti-expansion technology, applied in the field of refractory materials, can solve the problems of drilling steel, collapse, cracking, etc., and achieve the effect of reducing stiffness, reducing stress concentration, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

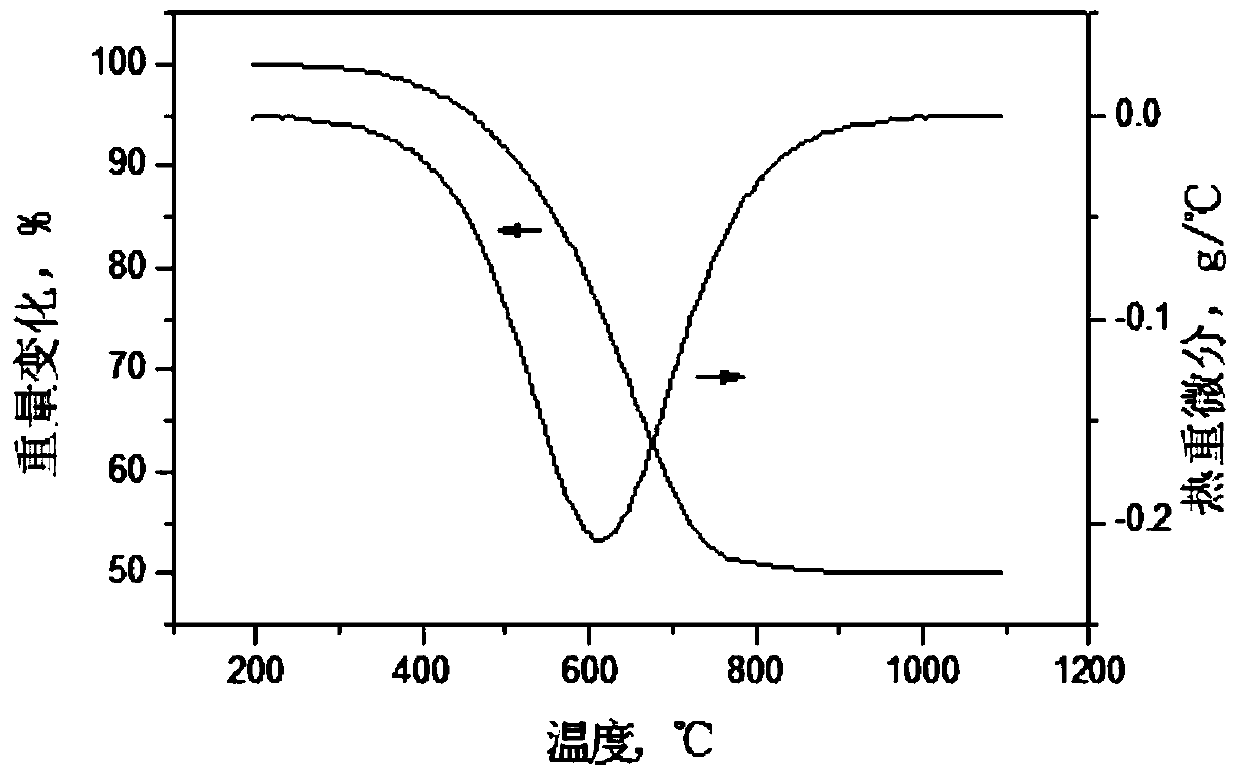

Image

Examples

Embodiment 1

[0027] A tundish dry working lining with anti-expansion and cracking, consisting of the following components:

[0028] The particle size of the composite resin powder is 1-150nm, the composite resin powder is phenolic resin, the mass fraction is 4.0wt%, and the mass percentage of hexamethylenetetramine in the phenolic resin powder is 10%.

[0029] The magnesia particles whose particle size is greater than 3mm and less than or equal to 5mm account for 19wt%, the magnesia particles whose particle size is greater than 1mm and less than or equal to 3mm account for 17wt%, and the magnesia particles whose particle size is greater than 0.088mm and less than or equal to 1mm account for 10wt%. The magnesia particle whose particle size is less than or equal to 0.088mm accounts for 28wt%, and the magnesia used is 95 dead-burned magnesia. The particle density of the magnesia is greater than or equal to 3.2g cm -3 .

[0030]The magnesite particles with a particle size of 1-3mm account fo...

Embodiment 2

[0036] A tundish dry working lining with anti-expansion and cracking, consisting of the following components:

[0037] The particle size of the composite resin powder is 1-150nm, and the composite resin powder is phenolic resin with a mass fraction of 3.0wt%. The mass percentage of hexamethylenetetramine in the phenolic resin powder is 6%.

[0038] The magnesia particles whose particle size is greater than 3mm and less than or equal to 5mm account for 16wt%, the magnesia particles whose particle size is greater than 1mm and less than or equal to 3mm account for 18wt%, and the magnesia particles whose particle size is greater than 0.088mm and less than or equal to 1mm account for 15wt%. The magnesia used is 95 dead-burned magnesia; magnesia particles with a particle size less than or equal to 0.088 mm account for 29 wt%, and the magnesia used is 97 fused magnesia. The particle density of the magnesia is greater than or equal to 3.2g cm -3 .

[0039] The magnesite particles wi...

Embodiment 3

[0045] A tundish dry working lining with anti-expansion and cracking, consisting of the following components:

[0046] The particle size of the composite resin powder is 1-150nm, the composite resin powder is phenolic resin, the mass fraction is 4.0wt%, and the mass percentage of hexamethylenetetramine in the phenolic resin powder is 16%.

[0047] The magnesia particles whose particle size is greater than 3mm and less than or equal to 5mm account for 16wt%, the magnesia particles whose particle size is greater than 1mm and less than or equal to 3mm account for 5wt%, and the magnesia particles whose particle size is greater than 0.088mm and less than or equal to 1mm account for 5wt%. The magnesia particle whose particle size is less than or equal to 0.088mm accounts for 28wt%, and the magnesia is 91 dead-burned magnesia. The particle density of the magnesia is greater than or equal to 3.2g cm -3 .

[0048] Dolomite particles with a particle size of 1-3mm account for 18%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com