Bearning mechanism

A technology of bearings and bearing parts, which is applied to sewing machine components, needle seats for sewing machines, textiles and papermaking, etc. It can solve the problems that pins cannot maintain hardness or size, it is difficult to reduce costs, and high processing costs are easy to process, The effect of suppressing processing costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

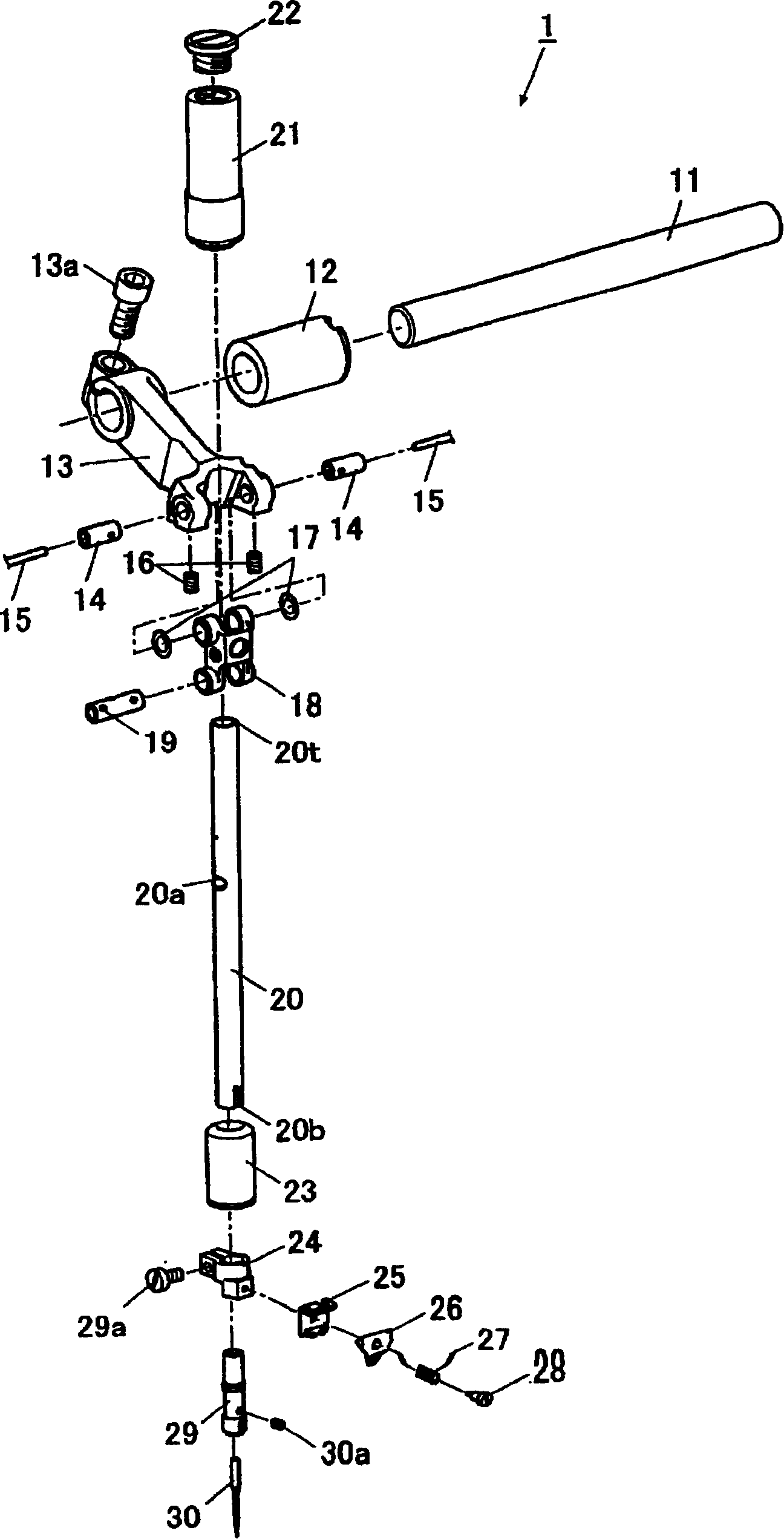

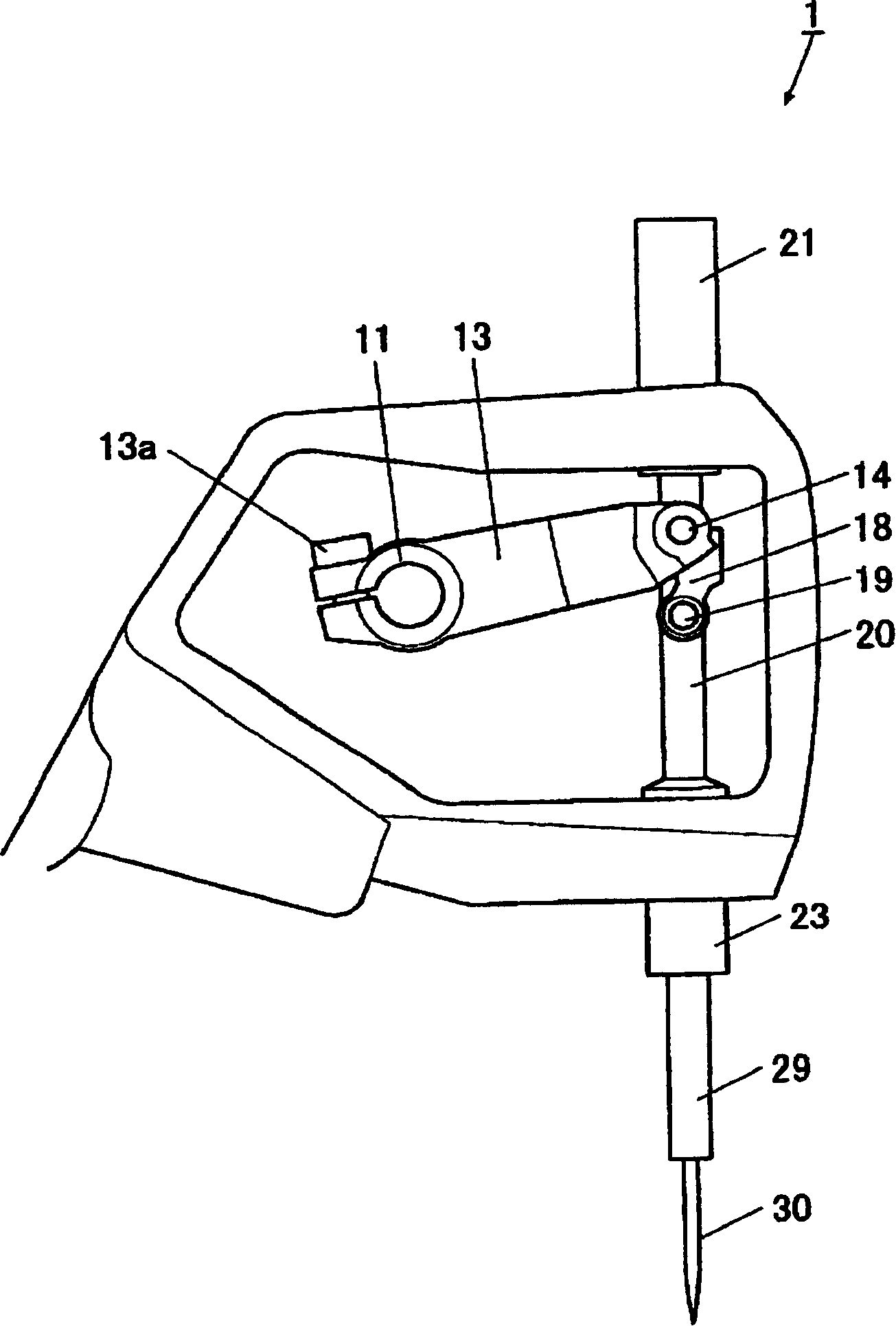

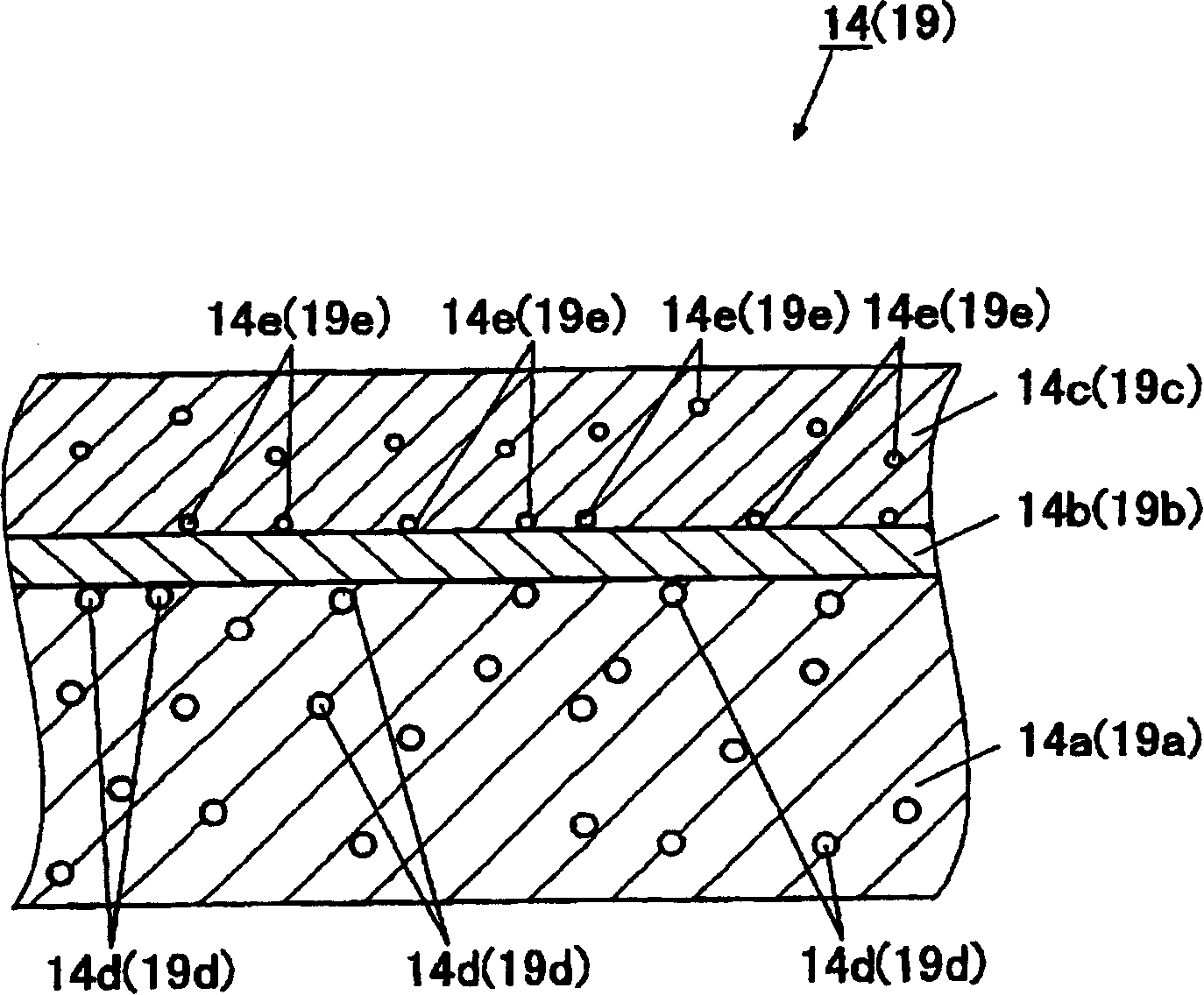

[0043] Next, the best mode of the bearing mechanism, the needle bar driving mechanism of the sewing machine and the looper mechanism of the sewing machine according to the present invention will be described with reference to the accompanying drawings. In addition, in this embodiment, the needle bar drive mechanism of the sewing machine which has a bearing mechanism, and the looper mechanism of a sewing machine are demonstrated.

[0044] (needle bar drive mechanism of sewing machine)

[0045] Such as figure 1 and figure 2 As shown, the needle bar driving mechanism 1 of the sewing machine (hereinafter referred to as the needle bar driving mechanism 1) has a needle bar driving shaft 11 that transmits the driving force from the sewing machine motor and swings. On one end of the needle bar driving shaft 11, a bolt 13a is equipped with drive shaft bearing bush (metal) 12 and needle bar drive handle 13. The needle bar driving handle 13 is formed to extend in a direction substant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com