Cylinder shape pipe piece with inner harden layer and its production method and equipment

A hardened layer and inner surface technology, which is applied to cylindrical pipe fittings with inner surface hardened layers and its production and special equipment fields, can solve the problem that it cannot be used for processing thin-walled pipe fittings, the work efficiency is difficult to improve, and the pipe fittings have different rotations. problems such as heart, to achieve the effect of facilitating transportation, construction and installation, stable work, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

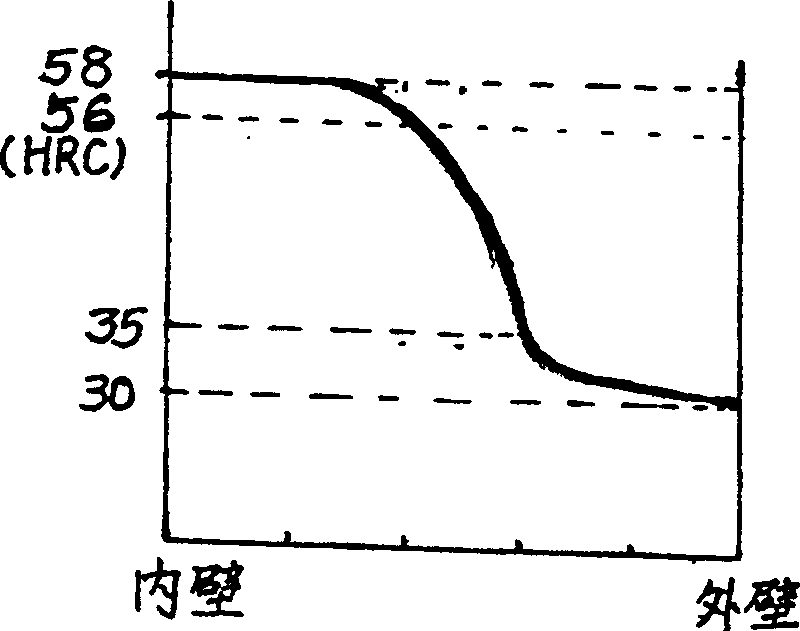

[0041] Embodiment 1 In order to meet the above requirements, use medium carbon steel or medium carbon alloy steel as the material of the pipe body, such as 45Mn2 alloy, the wall thickness of the pipe body can be selected from different specifications such as 4mm, 5mm, 6mm, etc., and the pipe fittings are quenched by the inner wall of the pipe The process makes the inner wall of the pipe form a hardened layer with a wall thickness of about 2-2.5mm, and its hardness reaches HRC55-60. If the hardness exceeds HRC60, the brittleness of the pipe wall will increase and cracks will easily occur; if the hardness is lower than HRC55, it will wear will appear more obvious. The wall thickness range from outside the hardened layer to the outer wall of the pipe still maintains the original hardness HRC30-35, and the length of the above-mentioned cylindrical pipe is 1-7 meters. In practical applications, 3-4m pipes are common.

Embodiment 2

[0042] Example 2 The preferred implementation of the above-mentioned pipe fittings is that the hardness of the hardened layer is HRC56-58, the wall thickness of the pipe body is 4.5-5 mm, and the length is 3 meters.

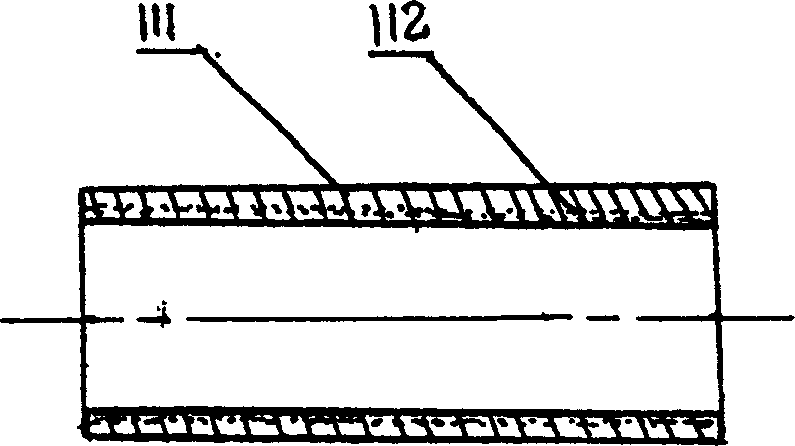

[0043] figure 1 It is a schematic diagram of the internal structure of the quenched pipe fitting. As shown in the figure, there is a hardened layer 112 within a certain thickness range of the inner wall of the pipe fitting, and the thickness of the hardened layer is less than 1 / 2 of the wall thickness of the pipe fitting. Outside the hardened layer is a non-hardened layer 111,

Embodiment 3

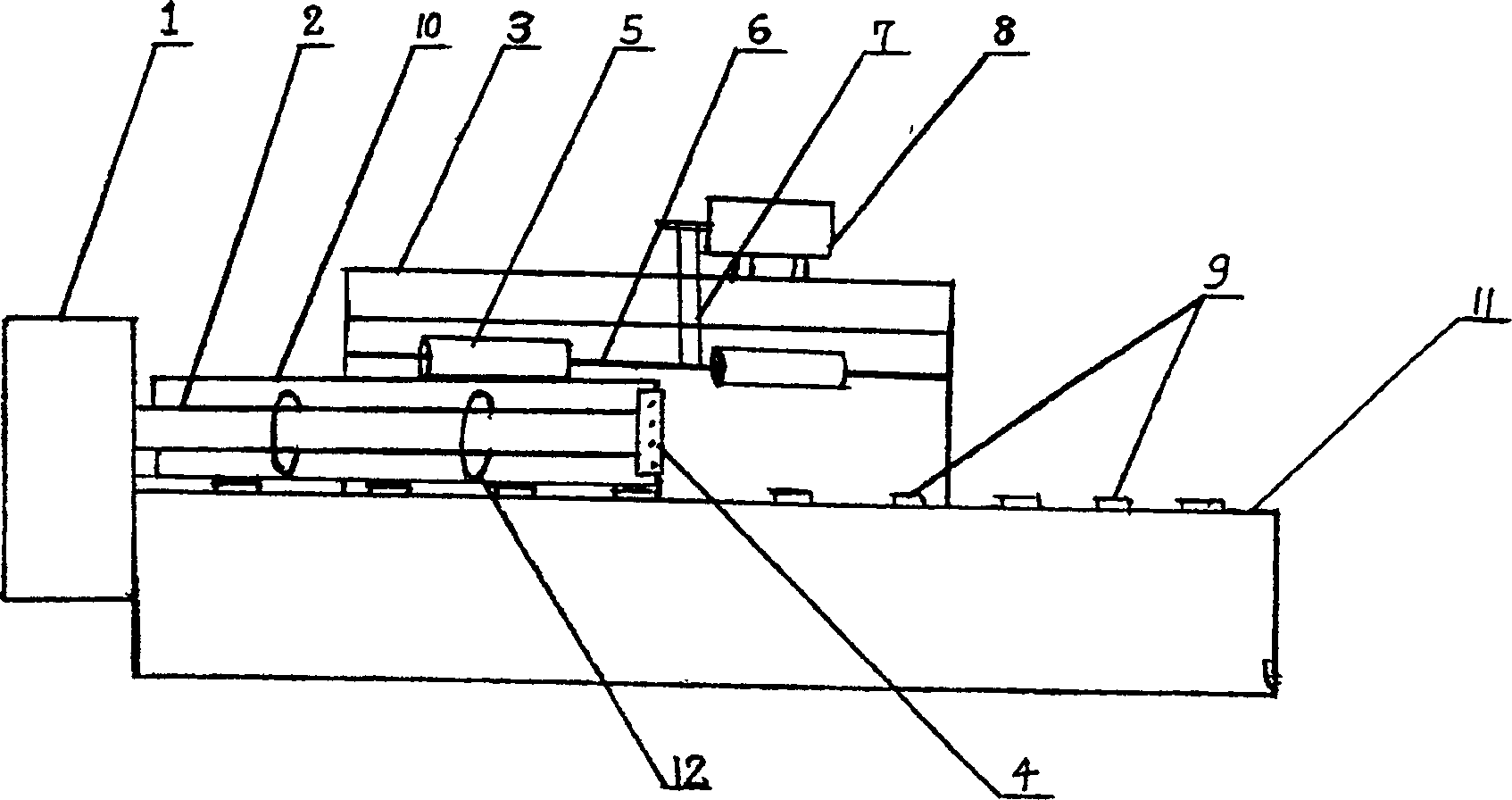

[0044] Example 3 The method for producing the above-mentioned pipe fittings is to adopt a high-frequency induction hardening process, that is, a quenching process in which the inner surface of the pipe is subjected to high-frequency induction heating and then rapidly cooled. The specific process is as follows:

[0045] a. The pipe is set horizontally and the high-frequency sensor is extended from one end of the pipe to the other port;

[0046] b. Make the cylindrical pipe part rotate around the axis and move backward along the axial direction; at the same time

[0047] c. Turn on the high-frequency sensor power supply. At this time, the anode voltage of the sensor is 10-12KV, the tank circuit voltage is 9-11KV, the anode current is 12-14A, the grid current is 8-9A, and the sensor generates 200-250KHz high-frequency electromagnetic oscillation , the speed of the motor is 7-10Hz;

[0048] d. The tube around the sensor is heated from the inner wall of the tube to no more than 1 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com