Optical proximity effect correcting method

A technology of optical proximity effect and pattern, applied in optics, originals for opto-mechanical processing, opto-mechanical equipment, etc., to achieve the effect of improving process margin and reducing deformation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

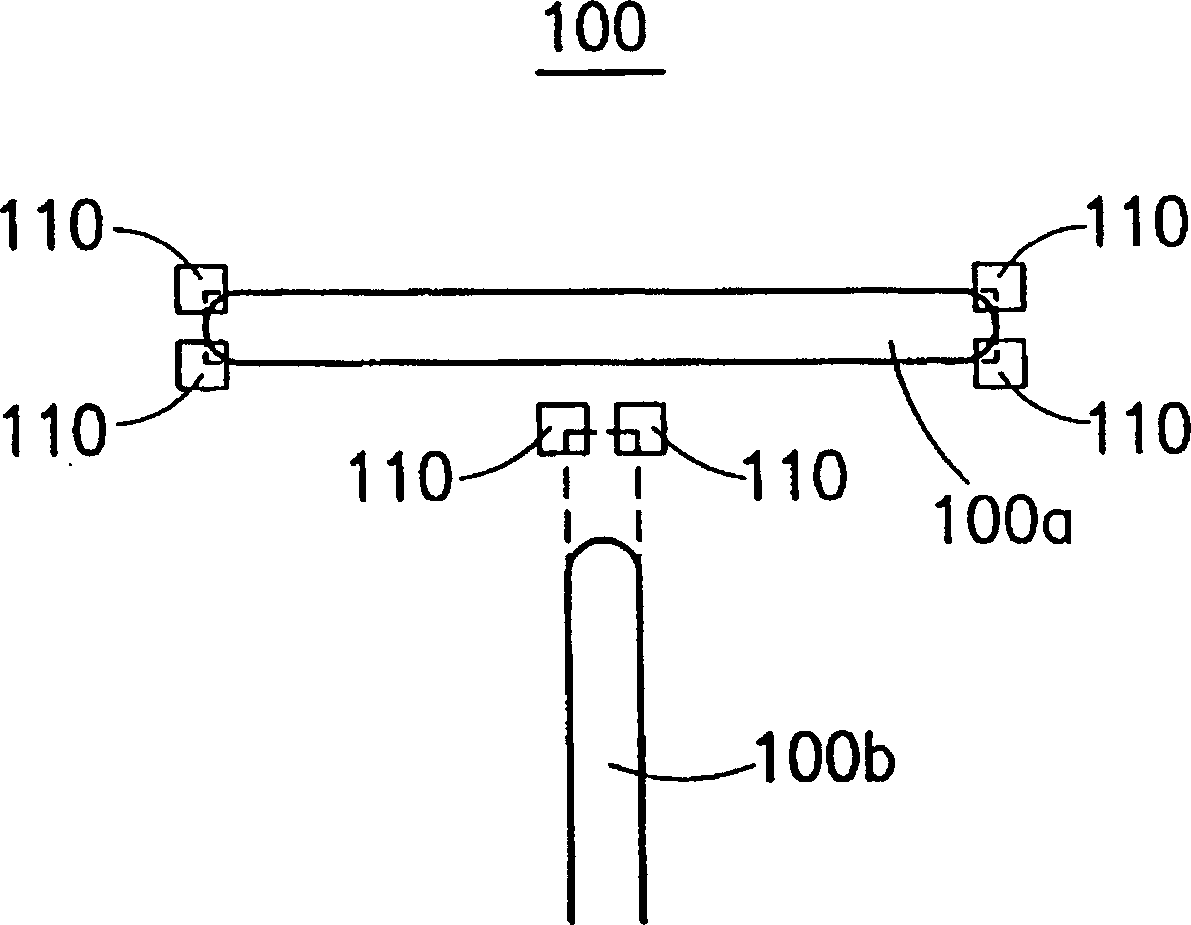

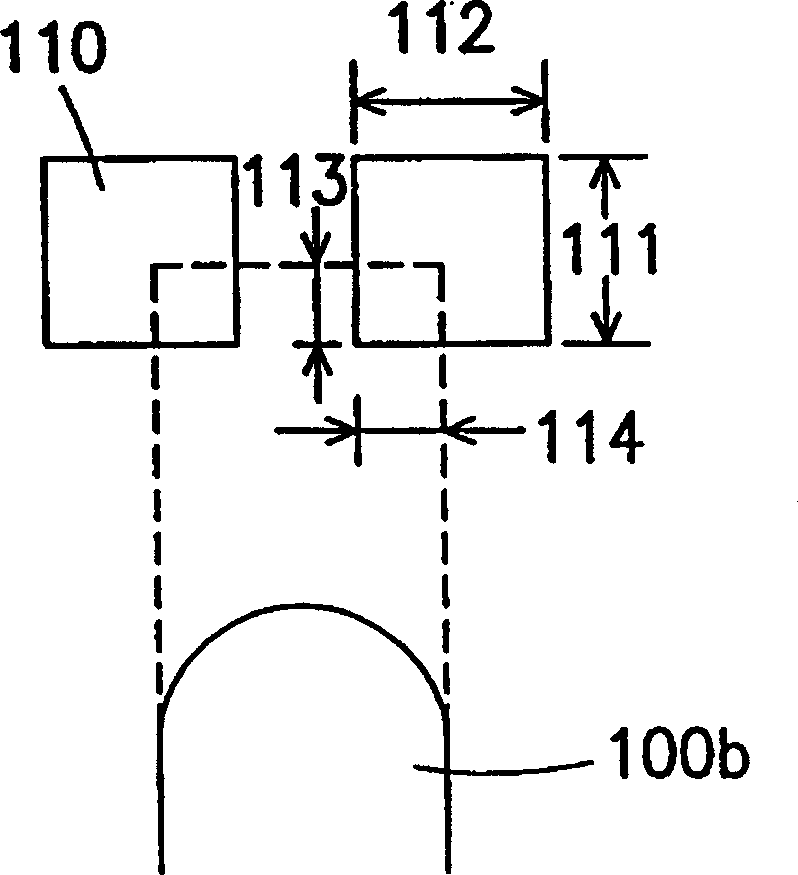

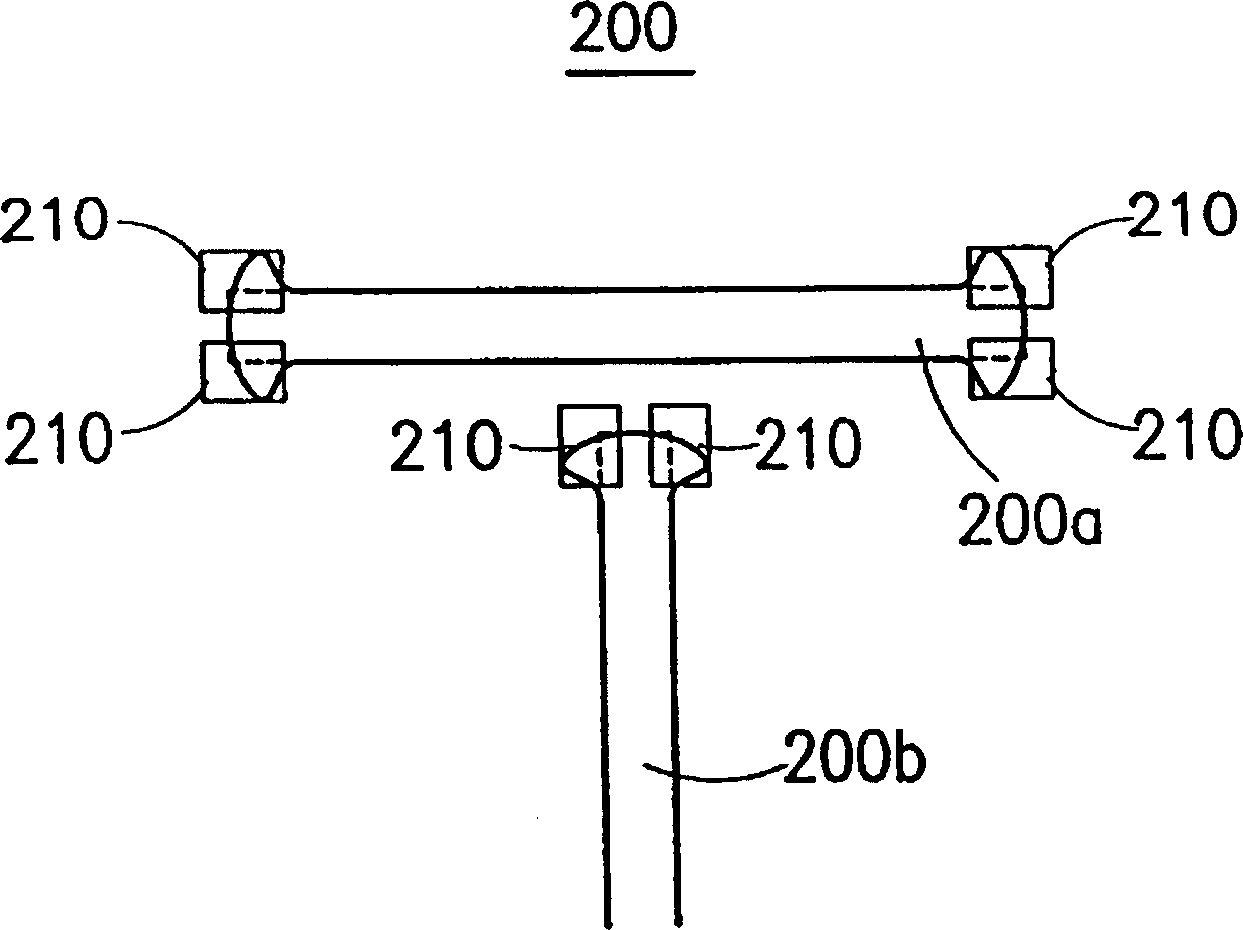

[0029] Generally speaking, the equipment used in the lithographic etching process includes a reticle, also known as a mask, with a pattern on the reticle corresponding to a pattern on a certain layer of an integrated circuit. Typically, the wire mesh consists of a glass plate covered by a defined opaque layer, eg chrome. During exposure, the wire grid is placed between the wafer and the light source. When the light source is incident on the wire grid, the light will pass through the glass layer not covered by the opaque layer and project to a photoresist layer on the wafer. In this way, the pattern on the wire net is transferred to the photoresist layer.

[0030] As mentioned above, due to the refraction or interference of light passing through the mask during exposure, and other factors in the manufacturing process, the transferred pattern is deformed. In order to make the transferred pattern realistic and reduce its deformation, the present invention provides a method for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com