Corner pumping method for plate strip and its solid laser gain module

A solid-state laser, gain module technology, applied in excitation methods/devices, lasers, laser components, etc., can solve the problem that the pump light cannot be coupled into the interior of the slab, the high power expansion of the laser is difficult, and the high absorption efficiency cannot be obtained. and other problems, to reduce the thermal lens effect and stress birefringence effect, improve the pumping uniformity, and improve the overall efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

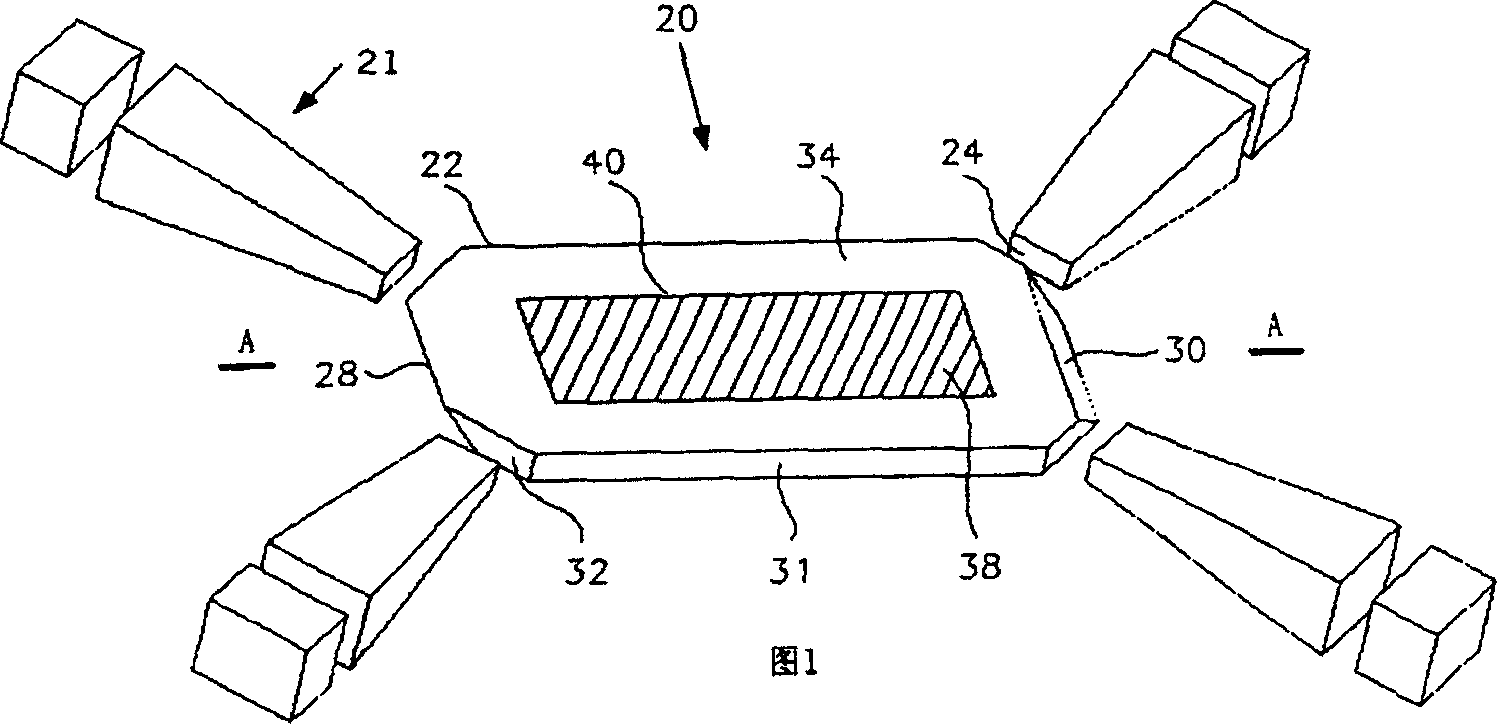

[0020] FIG. 1 is an overall structural diagram of a solid-state laser gain module of the present invention. The gain block 20 includes a strip 22 and four pump sources 21 . The cross section of the slats 22 is rectangular or square, with opposite incident surfaces 28 and exit surfaces 30 , four side surfaces 31 and four corner surfaces 32 . The corner faces are not limited to 4, but may be 8 or more.

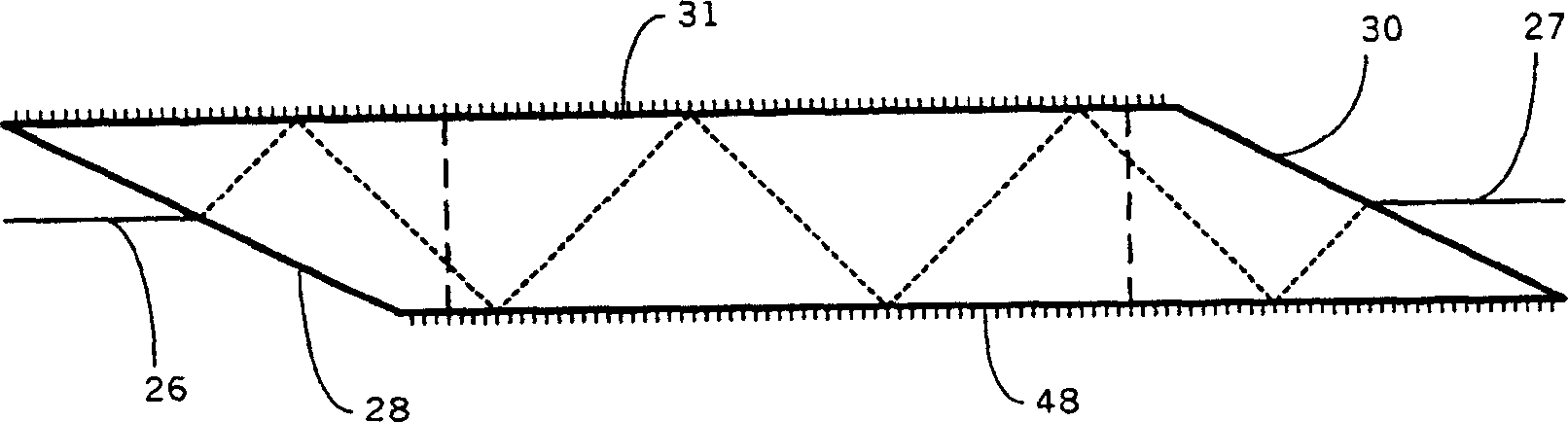

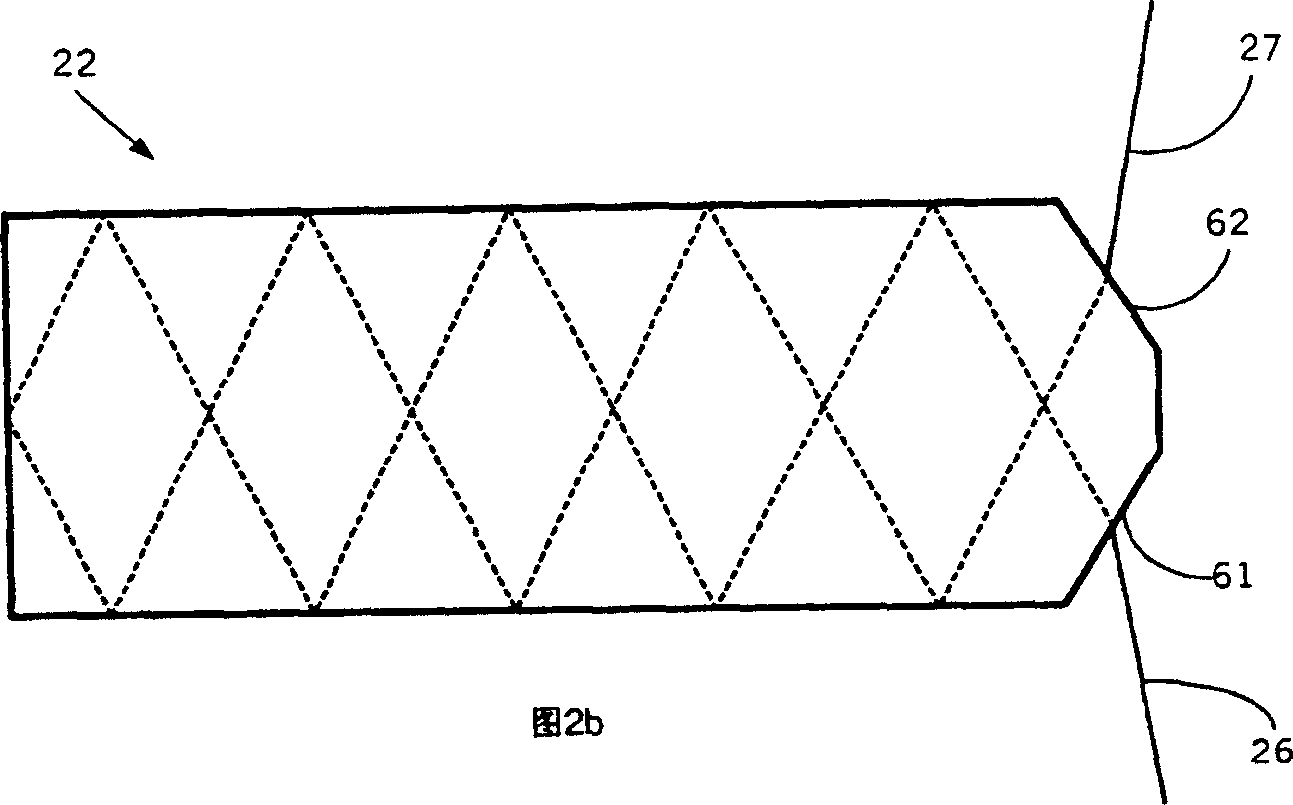

[0021] The slats 22 are composed of a high refractive index solid laser material. Due to total reflection, the incident beam 26 travels along a zigzag optical path between the two reflective surfaces within the slat, as in Figure 2a shown, this is called a zigzag amplifier. The zig-zag amplifier is able to homogenize the temperature gradient inside the slat to achieve uniform gain in the material. Thermal lensing and stress birefringence effects can be reduced by using zigzag optical paths, uniform pumping, four-corner injection, and thermal insulation at the edges of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com