Rib type coupled wear-resistant composite lining repair pipe and lining repair method

A repair method and technology for repairing pipes, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of inability to adapt to various application conditions, inability to apply to various construction conditions, single lining pipeline materials, etc., and achieve excellent Anti-wear performance and processing performance, avoiding inner tube collapse, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

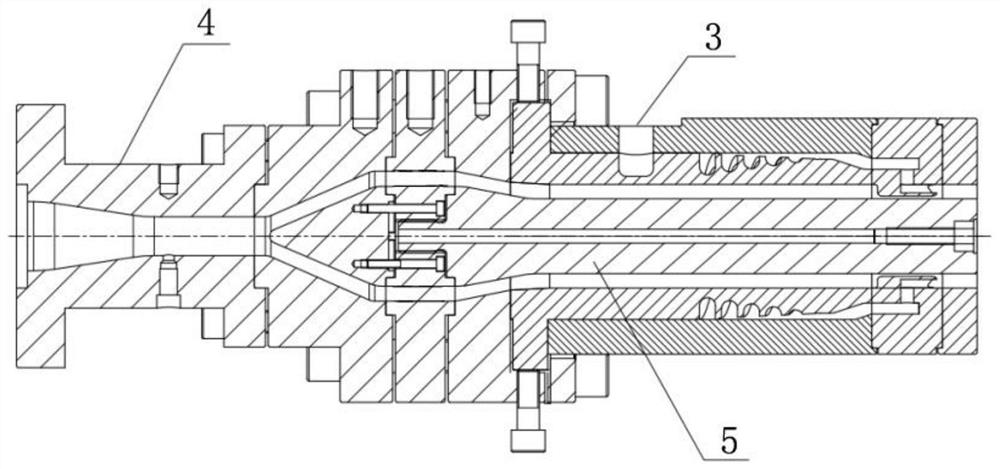

[0037] The present invention will be further described below with reference to the accompanying drawings and embodiments.

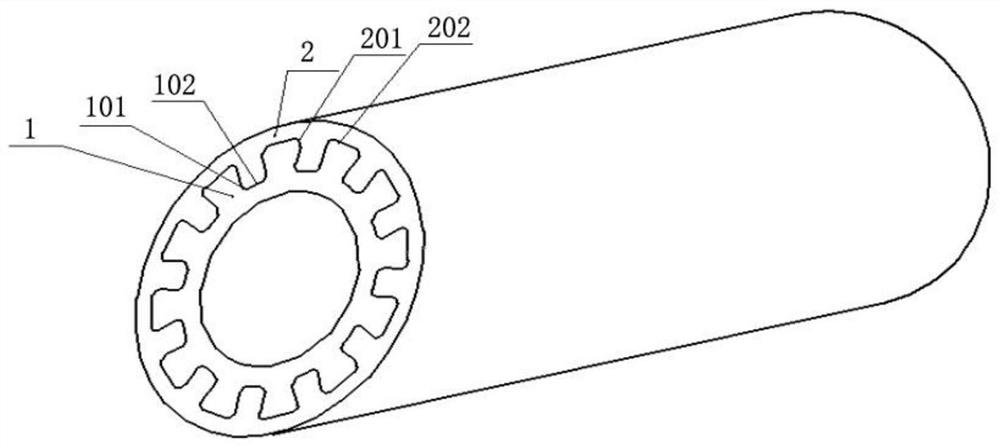

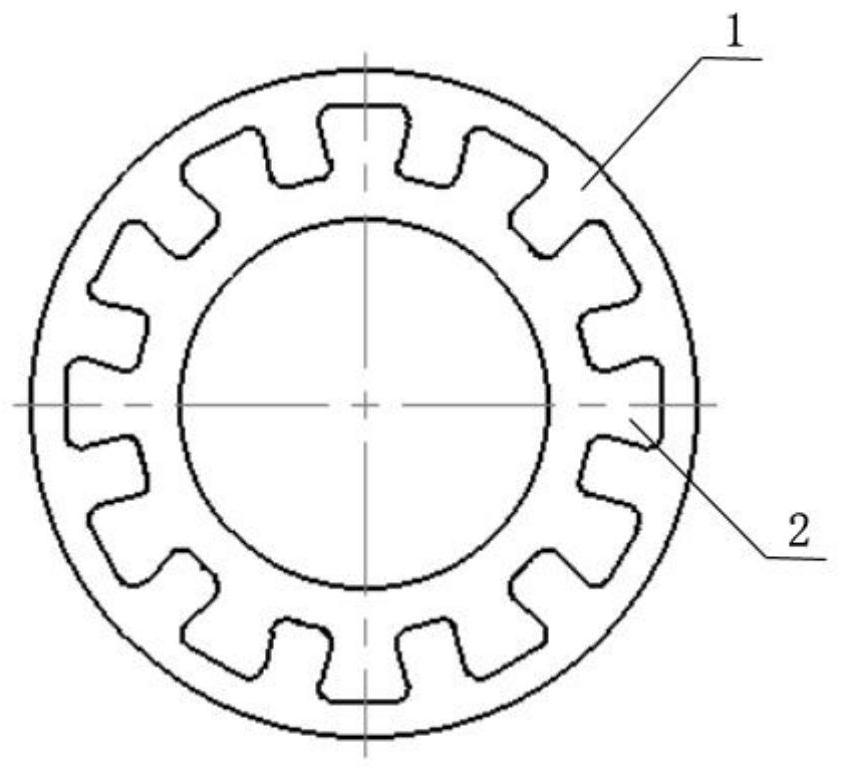

[0038] like Figure 1-5 As shown, a rib-type coupled wear-resistant composite lining repair pipe is mainly composed of an outer layer 2 (PE cladding layer) and an inner layer 1 (polyolefin elastomer wear-resistant material layer).

[0039] Among them, the inner layer 1 polyolefin elastomer wear-resistant material layer is a silicon-modified TPE material, which is chemically stable and corrosion-resistant, and has excellent wear resistance. It is 5*10 times that of steel pipes and 2-3 times that of ultra-high pipes. It is suitable for a variety of media, with low surface roughness and excellent hydraulic performance. Technical parameters of raw materials: density 0.9g / cm 3 , the melting index (190℃, 2.16kg) is 0.5g / 10min, the tensile strength is greater than 20Mpa, the elongation at break is greater than 600%, and the low temperature impact embrittlement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com