Phosphorus removal and chromium protection double process for smelting chromium-containing high-phosphorus molten metal from laterite-nickel ore

A technology of laterite nickel ore and molten metal, applied in the field of iron and steel metallurgy, can solve the problems of deterioration of molten metal performance, waste of chromium resources, etc., and achieve the effects of good rhythm matching, simple process operation and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Blast furnace produces chromium -containing high phosphorus and iron water pre -treatment.

[0043] 60 tons of iron water smelted by blast furnaces, see Table 1 when the iron is ranged. The phosphorus content is 0.094 %, and the chromium content is 4.32 %.

[0044] The high silicon containing this iron water will cause the temperature to rise quickly when AOD blows. Even if chromium is lost during blowing, it is difficult to effectively remove the phosphorus.

[0045] The method of removing chromium -to -chrome -keeping dual process is:

[0046] S1, first determine the final content of chromium -containing high phosphorus iron water after dehydration

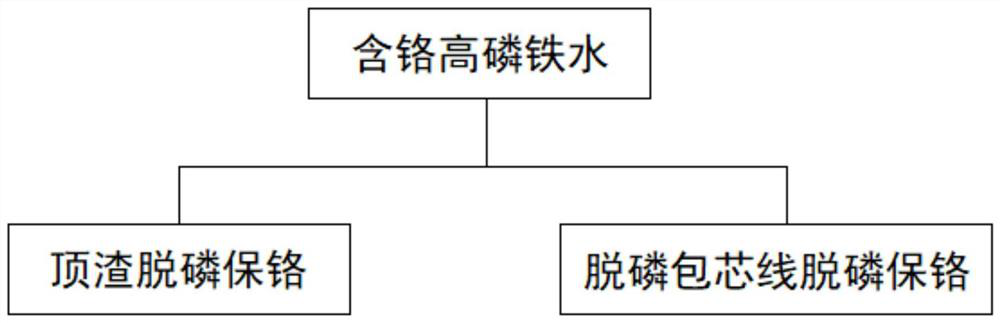

[0047] In order to reduce the loss of chromium in the subsequent AOD blowing process, such as figure 1 It is shown that when the blast furnace is used, the dual pre -phosphorus treatment process of the top residue and the chloropphorcin core wire in the iron bag is used.

[0048] S2. Determine the final content of the top res...

Embodiment 2

[0059] AOD produces the treatment of steel and water phosphorus in nickel stainless steel.

[0060] AOD steel water is 60 tons, and the phosphorus is exceeded in LF. The composition is shown in Table 2. The phosphorus content is 0.07 %, and the chromium content is 16.3 %.

[0061] The method of removing chromium -to -chrome -keeping dual process is:

[0062] S1. First determine the final content of the phosphorus after the steel -containing steel -containing steel -containing steel -containing steel water water water

[0063] Obviously, the difference between 0.05 % from the standard for the standard is not very large, which is equivalent to 0.2kg of phosphorus per ton of steel. Therefore, the dual dehydration process of the top residue and the chloropphorcin core wire is adopted in the LF.

[0064] S2. Determine the final content of the top residue and the chip phosphoring core wire according to the final content of the steel in the nickel -containing steel stainless steel.

[00...

Embodiment 3

[0075] AOD produces high -end nickel -chromium alloy steel in the process of excessive steel and phosphorus.

[0076] AOD steel water is 60 tons, and the phosphorus is exceeded in LF. The composition is shown in Table 3. The phosphorus content is 0.07 %, and the chromium content is 2.10 %.

[0077] The method of removing chromium -to -chrome -keeping dual process is:

[0078] S1, first determine the final content of high -end nickel -chromium alloy steel in the steel water water in the steel

[0079] High -end nickel -chromium alloy steel requires ultra -low -low phosphate content, and the phosphorus content should be less than 0.02 %. Therefore, the dual dehydration process of top residue and dehydration core wire is adopted in LF. The thickness of the top residue and the length of the dehydrated phosphorus core line is high, and the content of alkaline metal compounds is also high.

[0080] S2. Determine the final content of the top residue and the chloropphorcin core wire accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com