A kind of passivation method of corrosion-resistant steel for high-purity pipe

A kind of corrosion-resistant steel, pure technology, applied in the direction of metal material coating process, etc., can solve the problems of passivation layer density, thickness, limited number of layers, increased indirect cost loss, short service life of pipes, etc., to reduce electropolishing effect of time, promotion of preferential oxidation, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

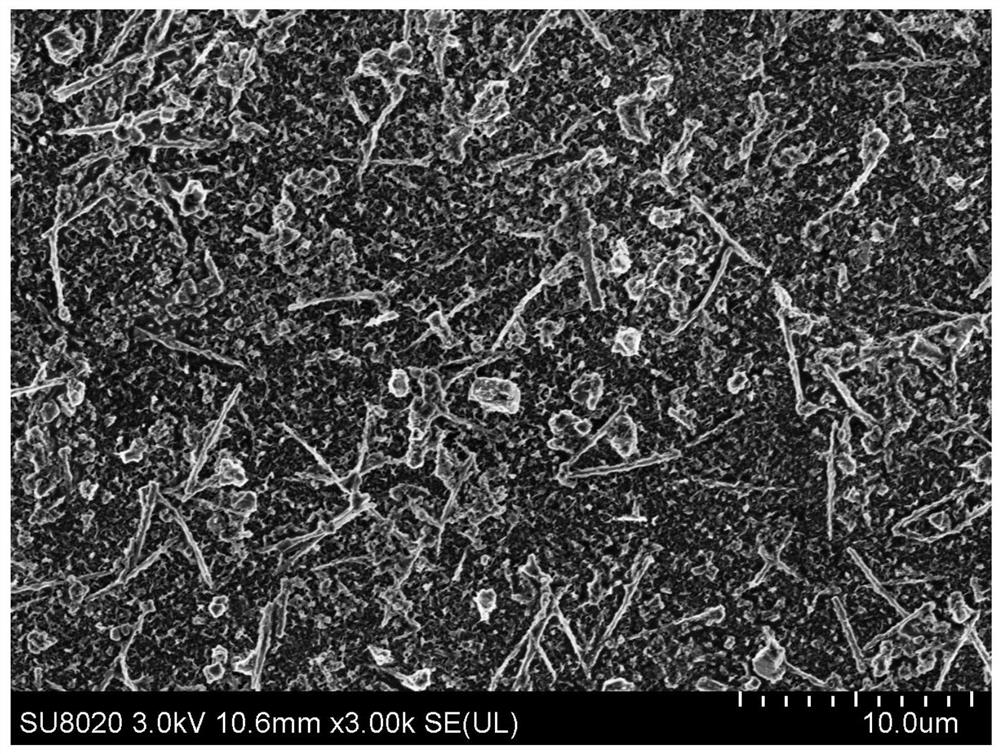

[0053] A passivation method for high-purity pipe 0Cr15Ni10MnMoWTiAlSc corrosion-resistant steel, comprising the following steps:

[0054] (1) Pre-passivation treatment: put the corrosion-resistant steel into a bright annealing furnace for heating, when the furnace temperature reaches 190 °C, start to pass cooling water; when the furnace temperature reaches 490 °C, pass nitrogen gas, and clean the furnace; when the furnace temperature reaches 530 °C When the temperature is ℃, oxygen is introduced into the furnace until the atmosphere in the furnace contains 23% oxygen, and the temperature is kept for 15 minutes, wherein the heating rate is 3 ℃ / min;

[0055] (2) Bright annealing treatment: after the pre-passivation treatment, hot nitrogen gas was introduced to clean the furnace chamber, and then ammonia decomposition gas was introduced to maintain the pressure in the furnace at 0.2MPa; the heating rate was controlled to be 3°C / min, and the temperature was increased to 1080°C. , ...

Embodiment 2

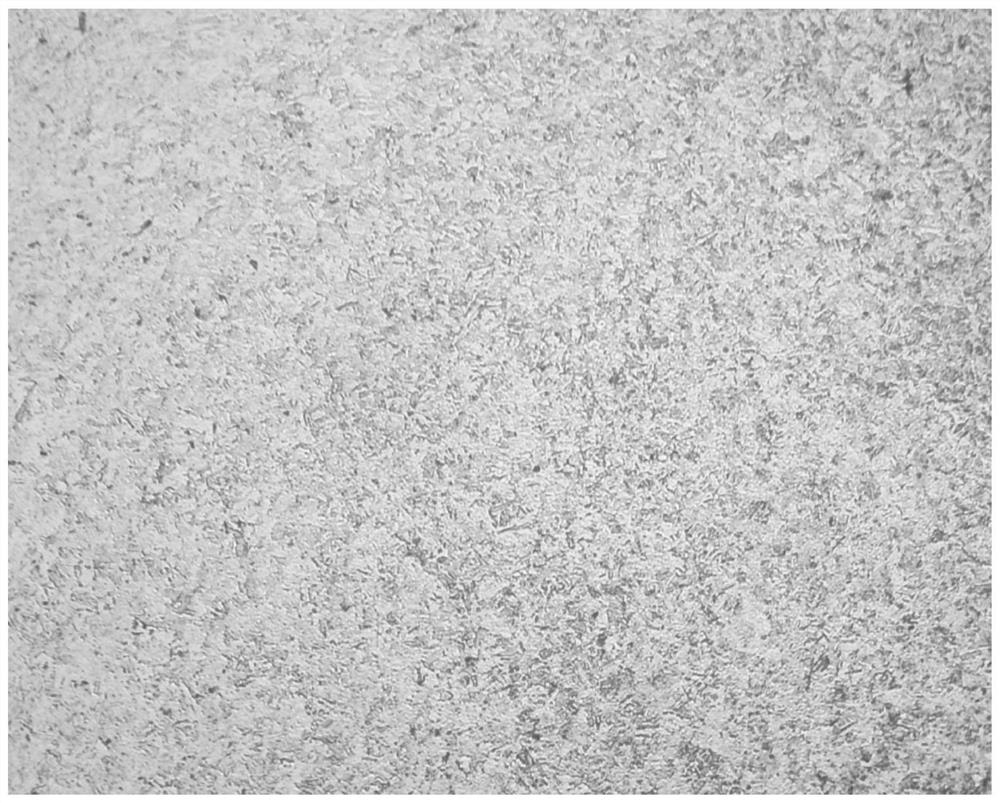

[0061] A passivation method for high-purity pipe 0Cr15Ni10MnMoWTiAlSc corrosion-resistant steel, comprising the following steps:

[0062] (1) Pre-passivation treatment: put the corrosion-resistant steel into a bright annealing furnace for heating, when the furnace temperature reaches 200 °C, start to pass cooling water; when the furnace temperature reaches 497 °C, pass nitrogen gas, and clean the furnace; when the furnace temperature reaches 540 At ℃, oxygen is introduced into the furnace until the atmosphere in the furnace contains 24% oxygen, and the temperature is kept for 17 minutes, wherein the heating rate is 5 ℃ / min;

[0063] (2) Bright annealing treatment: after the pre-passivation treatment, hot nitrogen gas is introduced to clean the furnace, and then ammonia decomposition gas is introduced to maintain the pressure in the furnace at 1.5MPa; the heating rate is controlled to be 4 °C / min, and the temperature is increased to 1100 °C After the heat preservation is comple...

Embodiment 3

[0069] A passivation method for high-purity pipe 0Cr15Ni10MnMoWTiAlSc corrosion-resistant steel, comprising the following steps:

[0070](1) Pre-passivation treatment: put the corrosion-resistant steel into a bright annealing furnace for heating, when the furnace temperature reaches 210 °C, start to pass cooling water; when the furnace temperature reaches 505 °C, pass nitrogen gas, and clean the furnace; when the furnace temperature reaches 550 °C When the temperature is ℃, oxygen is introduced into the furnace until the atmosphere in the furnace contains 25% oxygen, and the temperature is kept for 20 minutes, wherein the heating rate is 7 ℃ / min;

[0071] (2) Bright annealing treatment: after the pre-passivation treatment, hot nitrogen gas was introduced to clean the furnace, and then ammonia decomposition gas was introduced to maintain the pressure in the furnace at 2.5MPa; the heating rate was controlled to be 5°C / min, and the temperature was increased to 1120°C After the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com